-

Posts

37 -

Joined

-

Last visited

-

Days Won

11

Content Type

Profiles

Forums

Downloads

Events

Gallery

Blogs

Posts posted by WanV

-

-

-

-

-

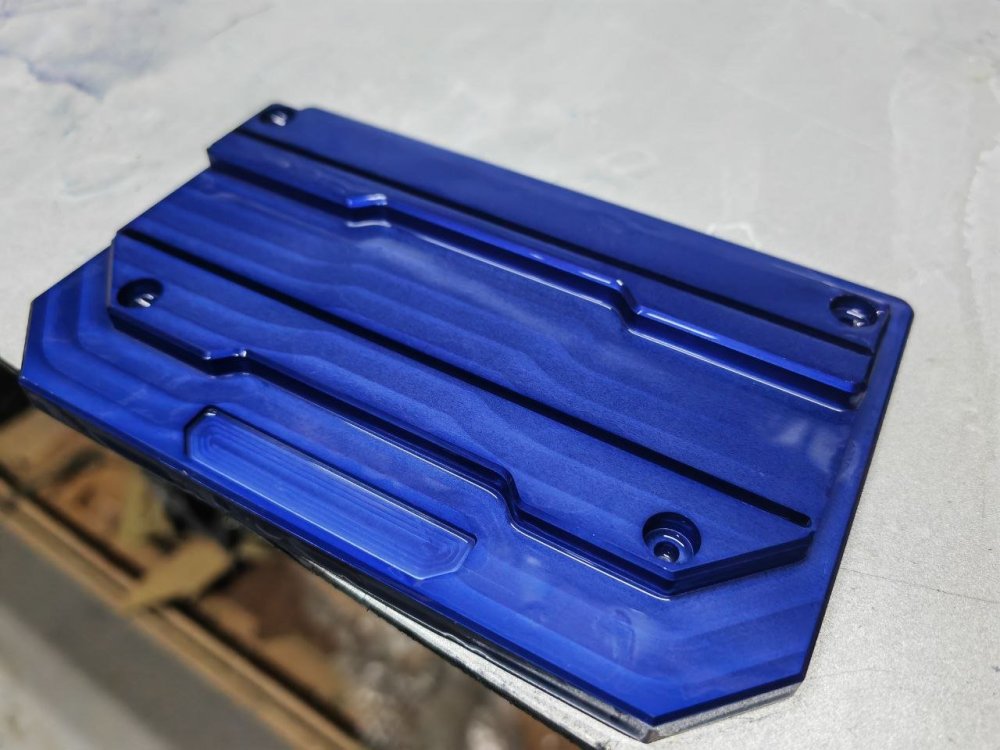

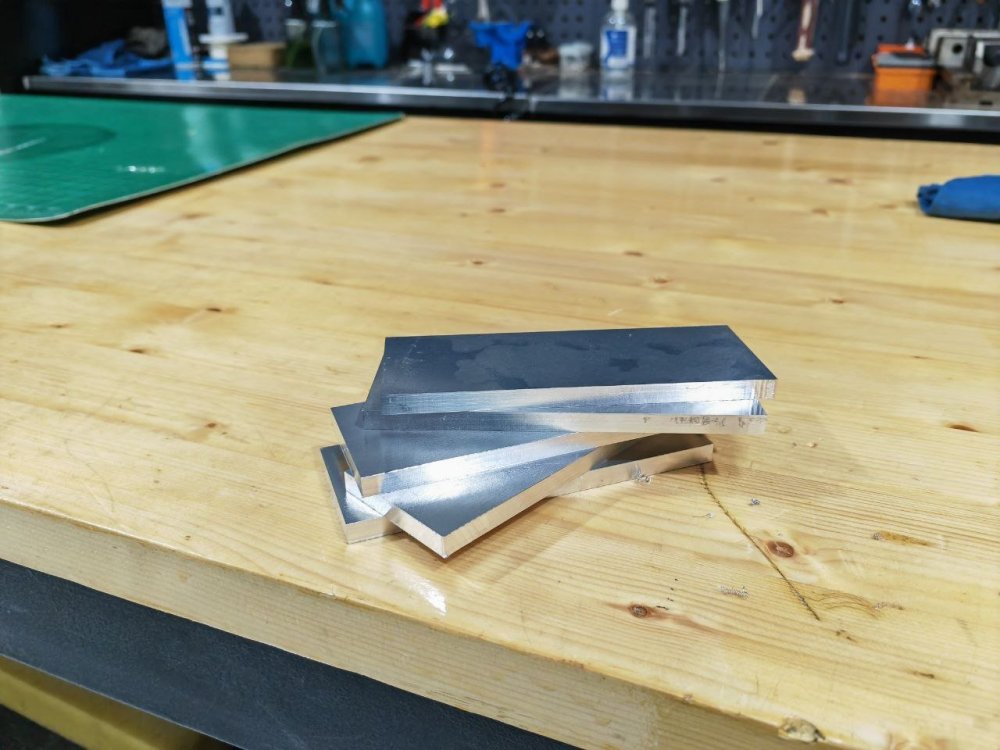

at the same time im doing some ram base to stick for showcase

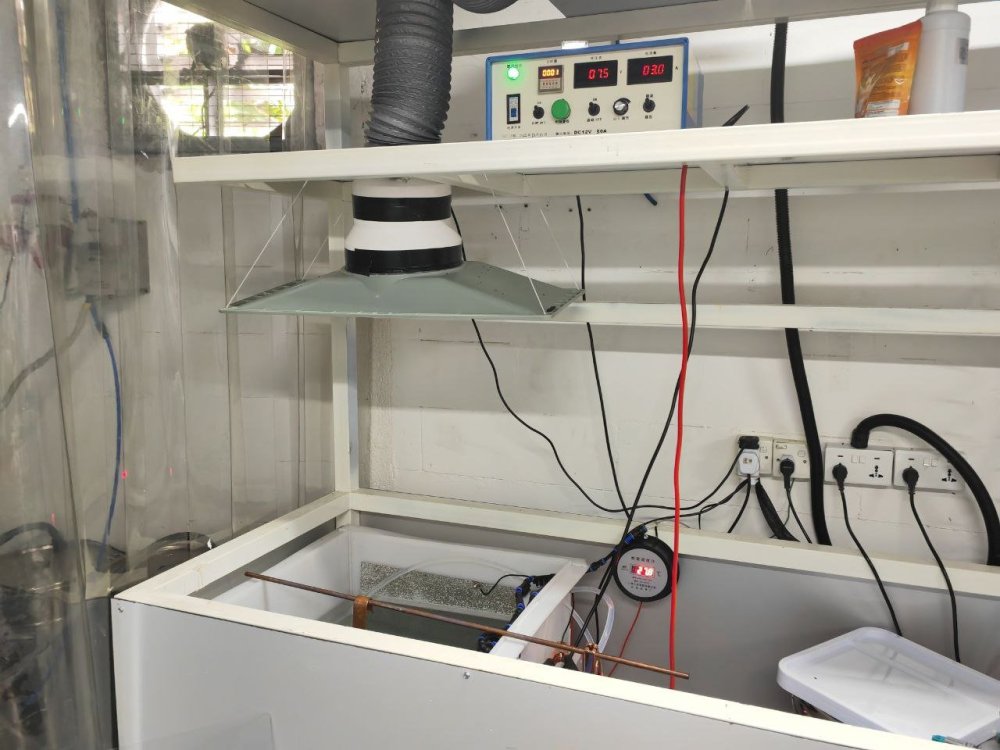

Cleaning the part to remove all grease with ultrasonic cleaner

the part look nice and clean

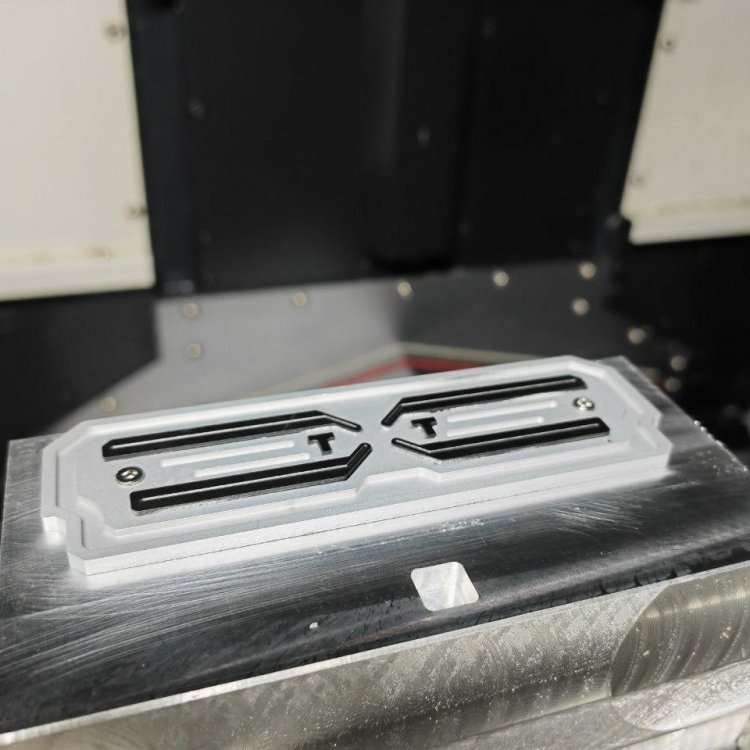

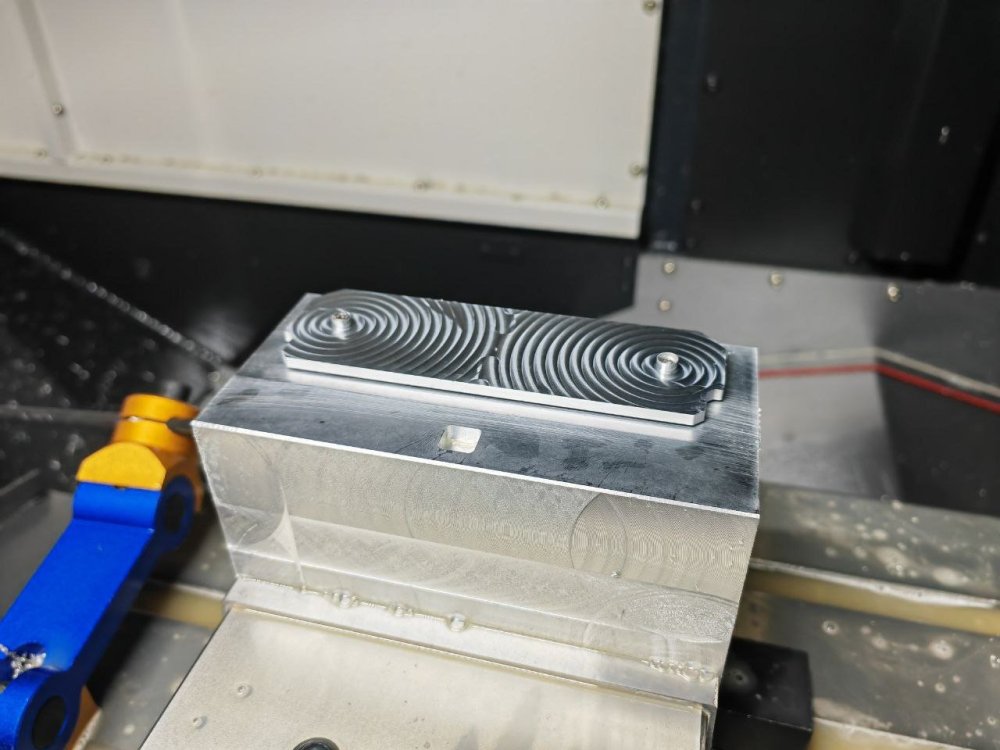

Etching process ,im not trying to remove all the tool mark just to make it less visible so it have some texture that why i am machine with that pattern

Etching with NaoH 2% solution to water its react very fast

-

-

-

-

-

-

-

-

my vote go for clerence while my case look right his looking left

-

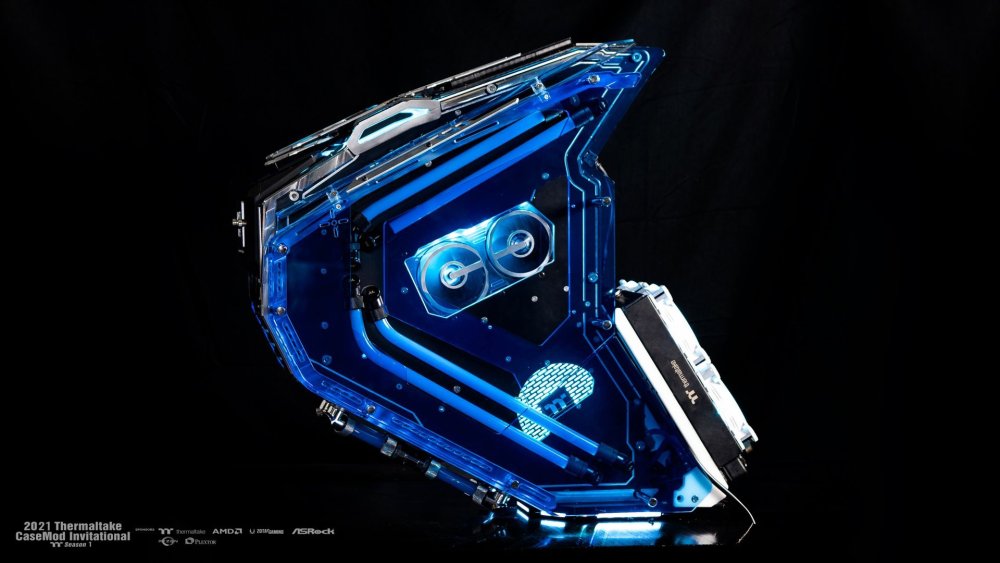

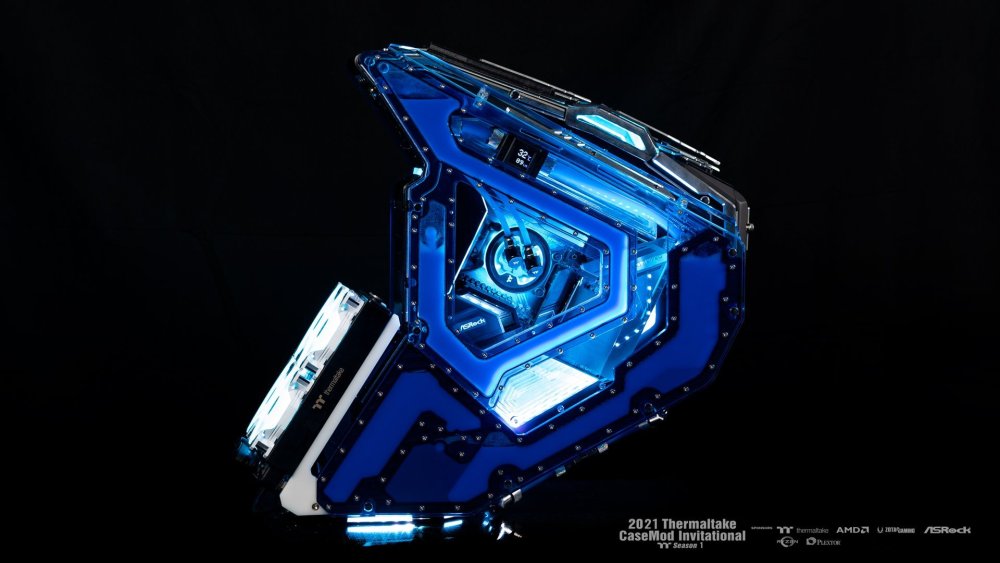

Thanks for all support and comment that all of you give me,overall my thought about this case mod is quite tiring and painful to be done,that true i use alot of part with cnc machine to have the shape but overall there alot of hand work and sanding to be done for finishing to get this effect for using such a cheap cnc machine that have finishing problem. alot of part need to be hand fix such a problem with roundness and material flex,overall its a satisfying result for me that i design with Fusion 360 took almost 3 weeks and the end product look exactly with what i imagine in design.

Final photo for PROJECT 0.6

sorry for video wobble we already use gimbal but forgot to calibrate, first time doing video sorry about that and enjoy

- MERRICK and Jean R built

-

2

2

-

-

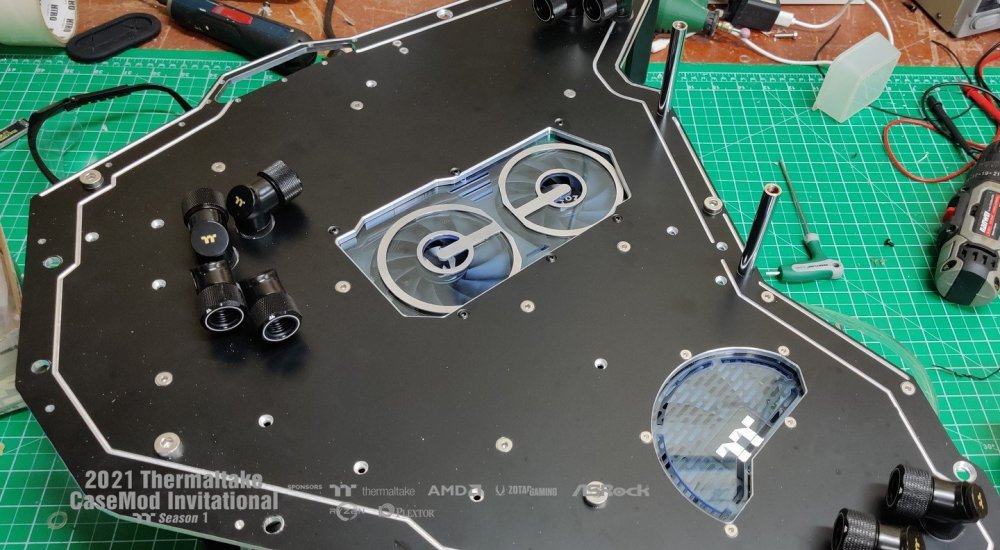

Right side of the case that i test fit before connect between original case panel and left middle panel.

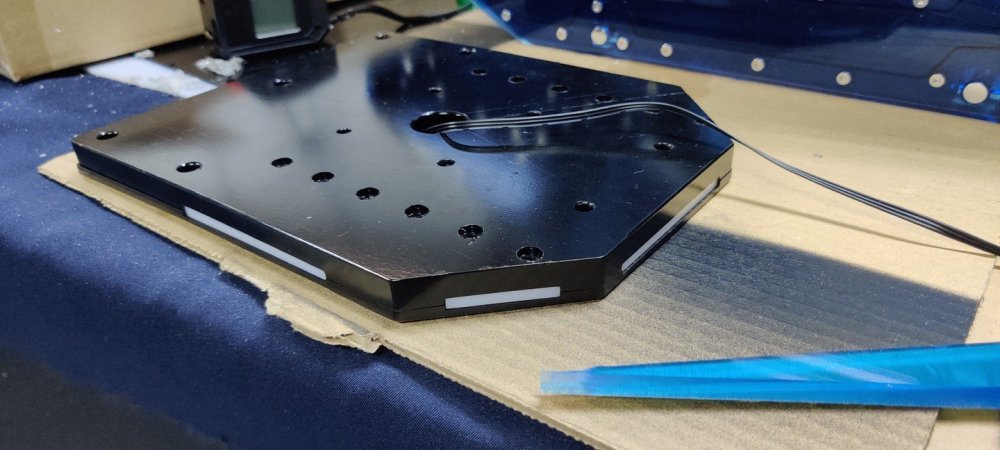

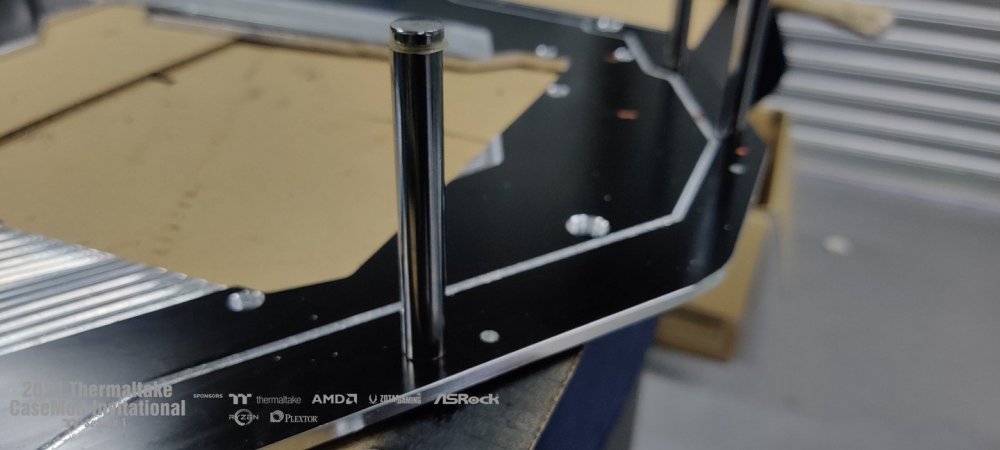

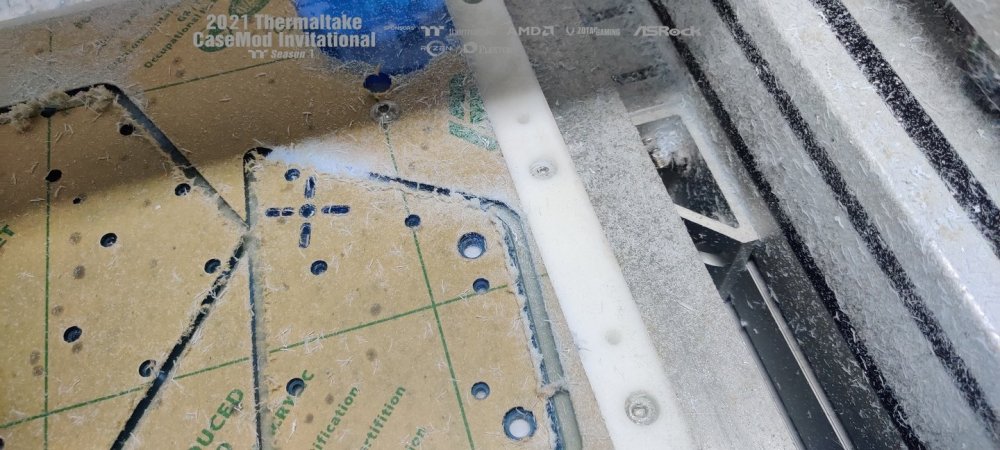

bottom side i need to tap all M3 thread to connect middle cover panel that thickness around 5mm only. so i have 1mm each side for clearance,pretty hard.

on of 3D printed part that i use in this build because lack of material and its hard to get new material ASAP this season

-

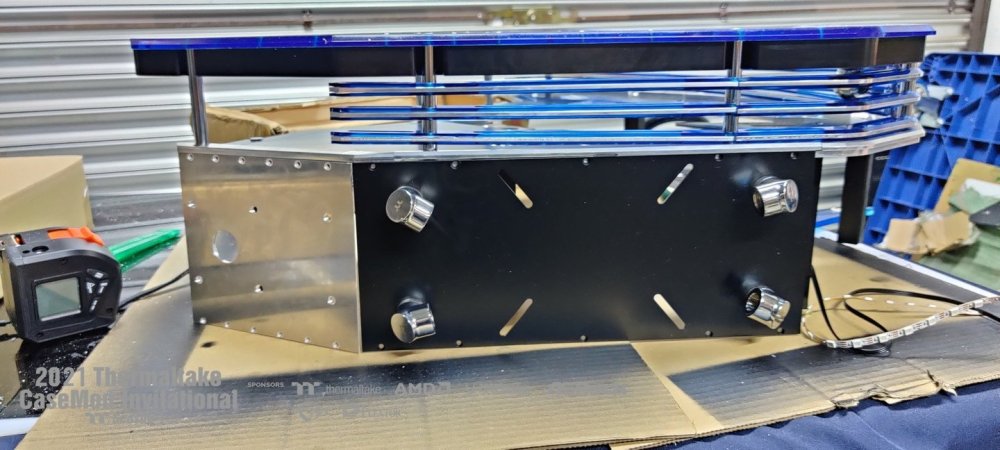

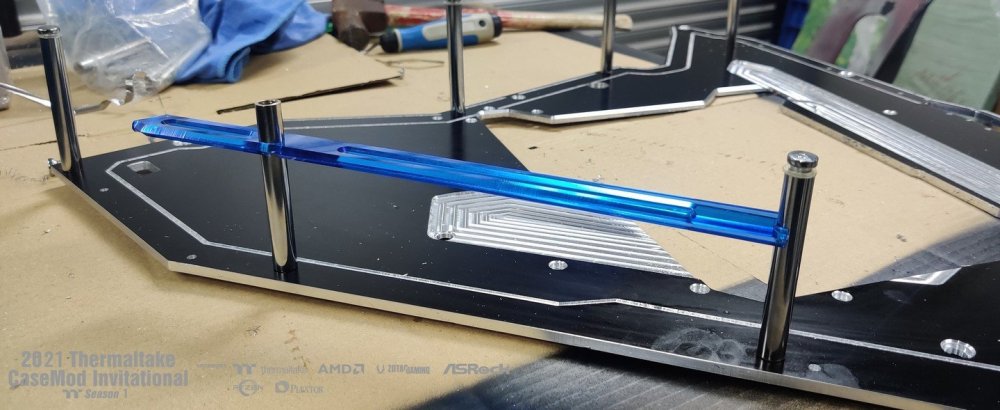

today start doing middle connector that need to connect middle left and right frame to support original case panel inside

chamfer side to remove sharp part

Since my cnc machine height is pretty low need to manual drill and make sure its pretty accurate if not it will bend the frame and probably wont fit,quite hard to get it got some scrap too.

-

-

-

-

-

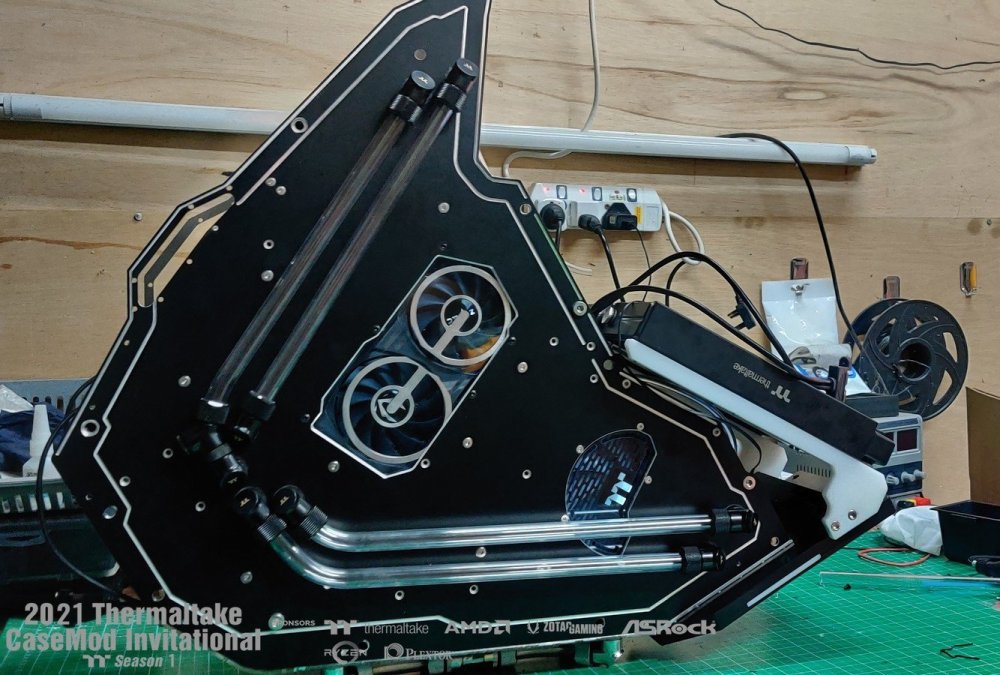

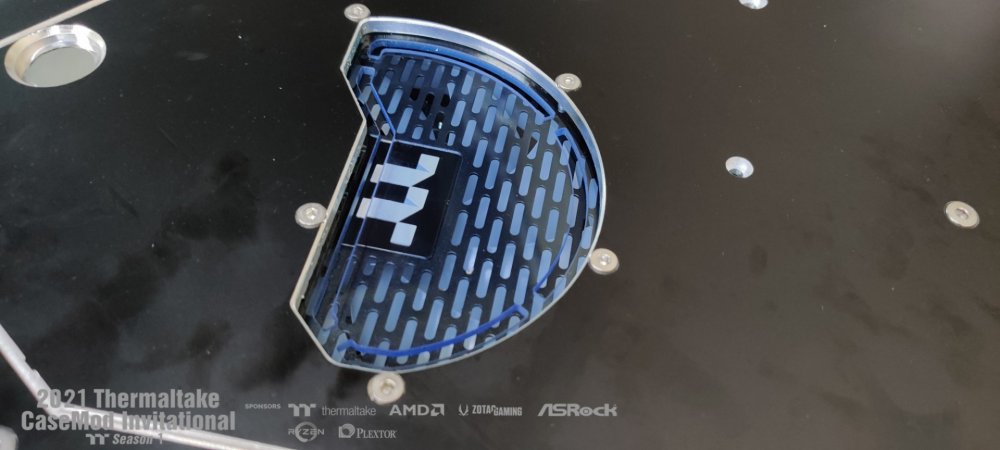

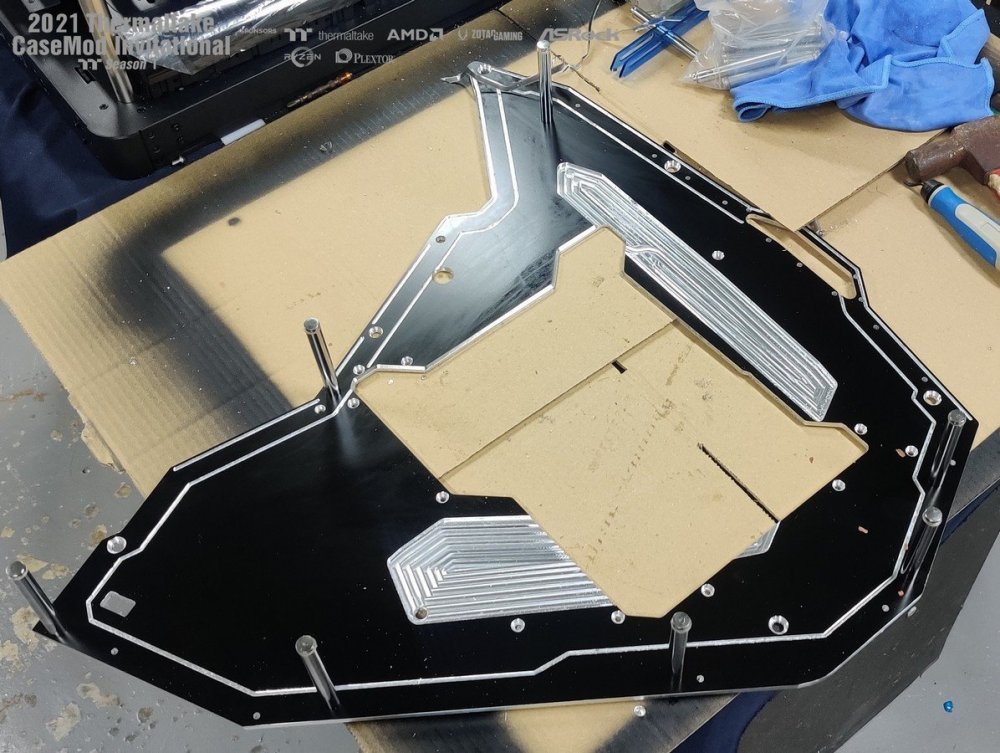

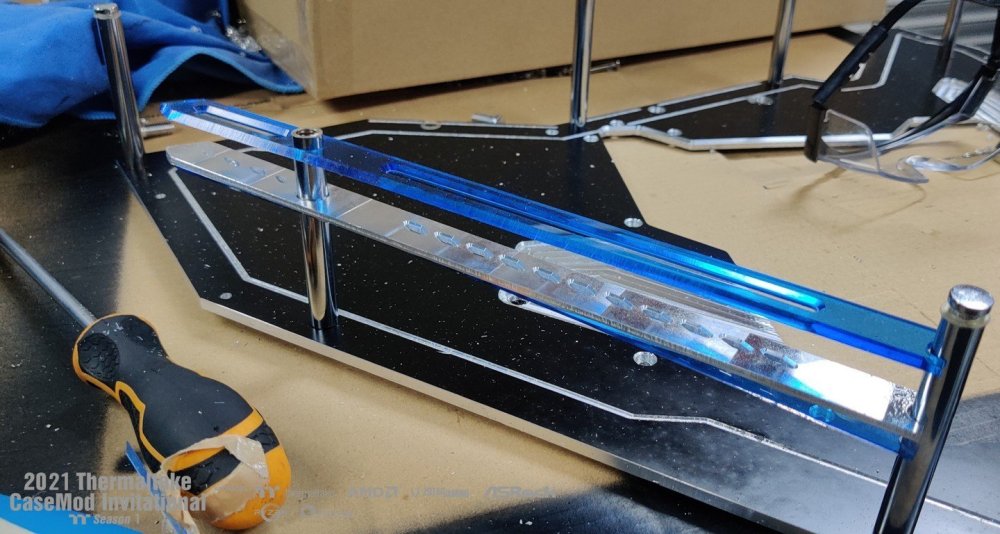

one of side panel done cutting now need to cut side blade that will have 3 part which is blue acrylic>alu 3mm>blue acrylic.

Cutting Side blade is quite hard since im using cnc router and its quite fragile and easy to flyout because of thin material,before cutting all countour im using 50mm face mill to get shiny effect after face milling, so overall i rather use thick material 😏since its easy to cut and set

after done cutting i do fit test to see it will fit or not since its just a cheap cnc machine sometime its hard to get a good round hole that need to fit the chrome rod.

-

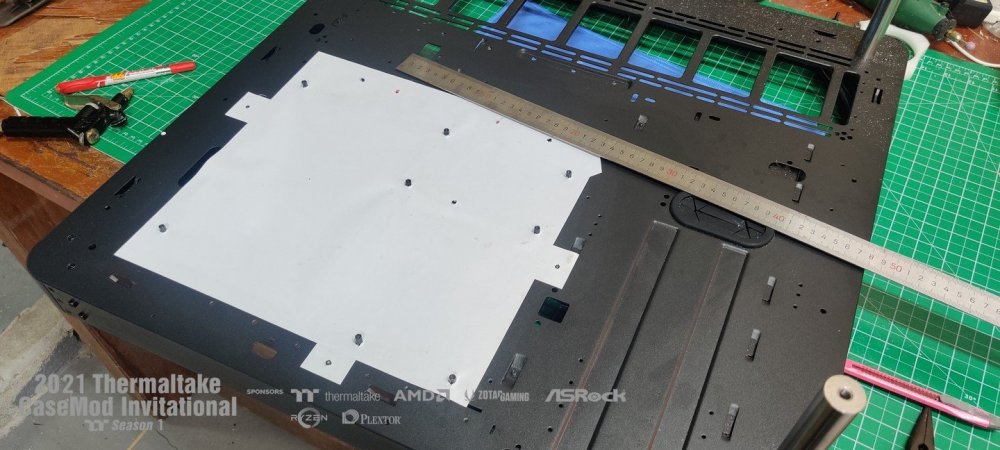

Testing and measure some part for design and cutting.and i need to make sure its right since most of my material i need to source it from china ,because im living at rural place and its take 1-2 month to get the material and i can go wrong with it.

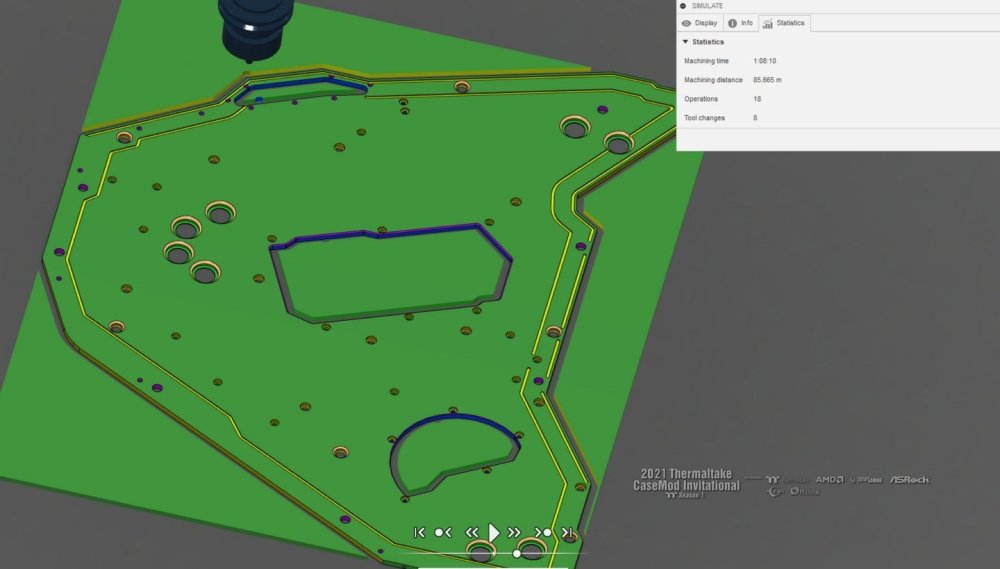

Cutting Process start for side distro and main panel ,its quite hard for me since it hitting all my machine size limit because the core p8 case is quite big

Machining time that take over 1-2 hours overall to finish plus need to do 2 side.

-

-

.thumb.jpg.fca84be277aa4f4254829686bcbcf3e1.jpg)

.thumb.jpg.65f52cb2daf7542f32575065c260246e.jpg)

.jpg.d75bb4cb31a7c280b00f8654b1040f52.jpg)

.thumb.jpg.72cbc8b7d562622f201d62d021fad9f2.jpg)

.thumb.jpg.825cf9266fb1839cadbc2dc9a225e4c9.jpg)

.jpg.20524d9f3836170d91d519f2eb75b5d9.jpg)

.thumb.jpg.7e4084e485c3a51e333c35e58fc9c6de.jpg)

.thumb.jpg.e0cd2ebee66aa2e96b928c2125b3bb61.jpg)

.thumb.jpg.31d8414913645a1a7000a538e01d45d2.jpg)

.thumb.jpg.4ebeea3be9f5b32bad3979c98135866f.jpg)

.thumb.jpg.205524c36dbf805382711da35e28bc98.jpg)

.thumb.jpg.27aa9afb47dbef7ca9d2868f5337b82e.jpg)

.thumb.jpg.ceee00f8b10714a30c63617e40d49dca.jpg)

.thumb.jpg.56e2eab3cb6f80b1080fc78faef386b8.jpg)

.thumb.jpg.b1736a1ae28d8c09f7fa00926b8d1072.jpg)

.thumb.jpg.33bd47866c79b0004084c7042c281c29.jpg)

.thumb.jpg.e38f8ab071df7f88f2aad3e8f8191ee0.jpg)

.thumb.jpg.cafd3cf9a4625df4bb413a4f85094f81.jpg)

.thumb.jpg.30265ab439c94cadf0ae7a65730cb330.jpg)

[Malaysia] Ahmad Safuan

in 2023 Thermaltake RAM MOD Invitational Season 1

Posted

Final Video