-

Posts

25 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Downloads

Events

Gallery

Blogs

Posts posted by Vinay Agrawal

-

-

-

-

-

-

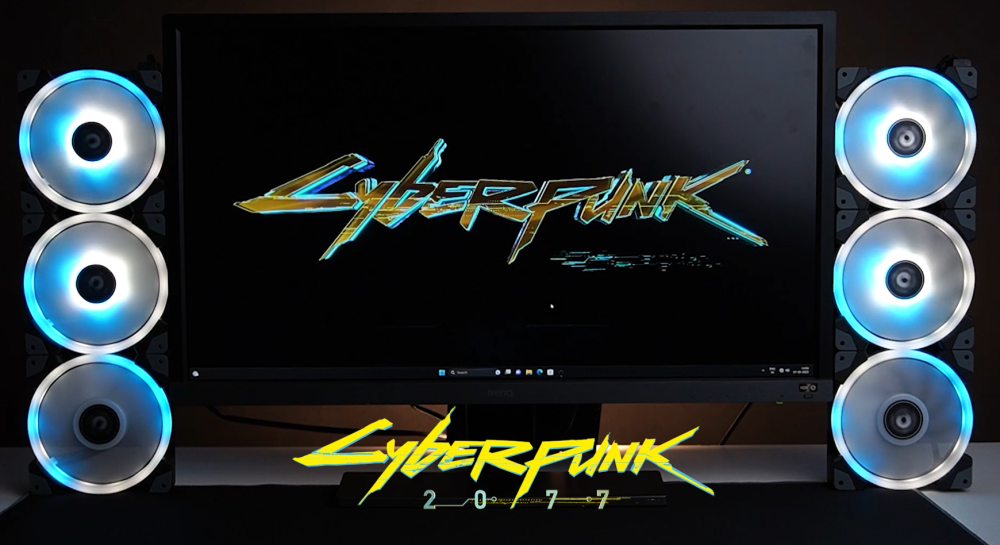

Here is the Video!! cheers !

https://youtu.be/NQ84J45qJ3U<iframe width="560" height="315" src="https://www.youtube.com/embed/NQ84J45qJ3U" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

-

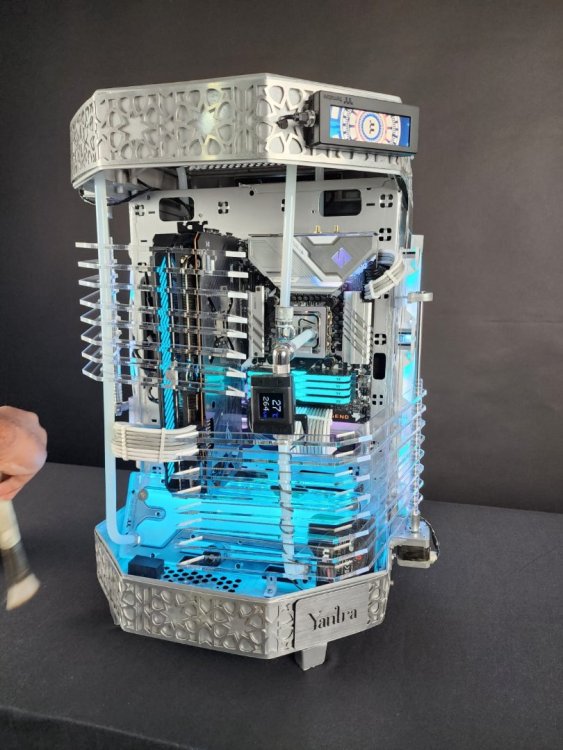

---------------------------FINAL UPDATE AND MOD PICS ----------------------------------------------

-----------------------------------------THANK YOU !! I Hope Everyone likes the build ! and enjoyed the process !--------------------------------------------------------------------

---------------------------------------------------------------------------------😄😄😄--------------------------------------------------------------------------------------------------- Andrew Makin and Anil Malche

-

2

2

-

changed the temporary screws used to Allen screws. to get a more plush look.

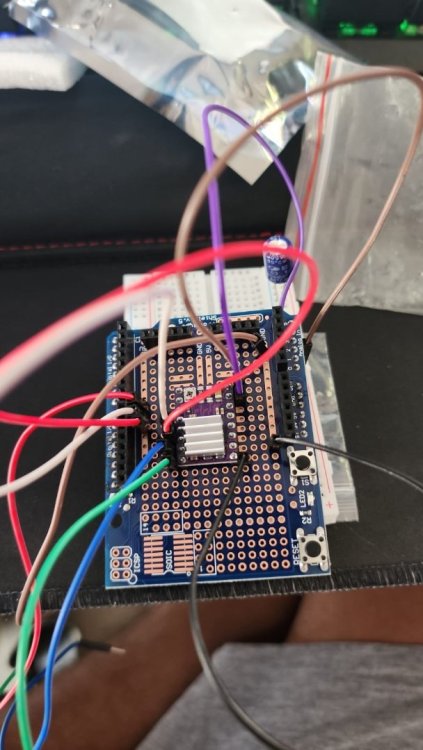

since the test fit was working with motors and Arduino, got this Prototype sheet to fit on Arduino to make it compact .

.thumb.jpeg.999ab85a7b3ae629f53a66877638e608.jpeg)

.thumb.jpeg.f1beef3cfe0cc0103485f42d1870dbe2.jpeg)

will be uploading the project files on the website incase someone needs it. This Arduino will be controllable from the machine itself .

Now the upper panels are in place,

will carry out some testing with the increased load of the acrylic panels.

test of temperatures and will play with Neon, maker for best looking RGB colors .

will be seeing you all with the final post after this !

thank you for following this thread and stay tuned for the final pics !!

.thumb.jpeg.a08fce00d98ac0bf979e95a03c06d27c.jpeg)

.thumb.jpeg.deb8d282801012dc289e779317e5a6b7.jpeg)

will do some dusting and polish to make it ready for the final shoot !

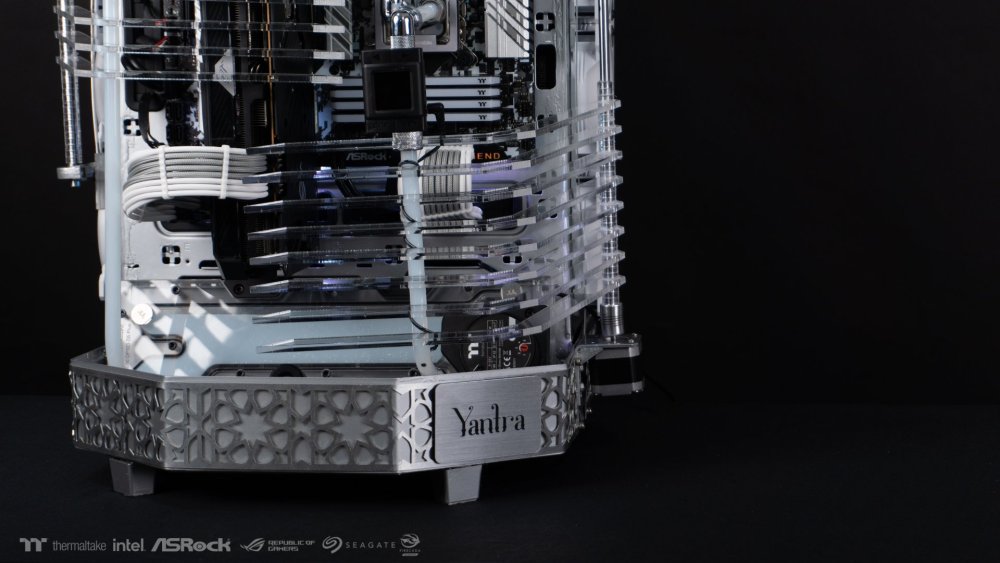

----------------------------------------------------------------------Project YANTRA--------------------------------------------------------------

Stay Tuned for final pics ! -

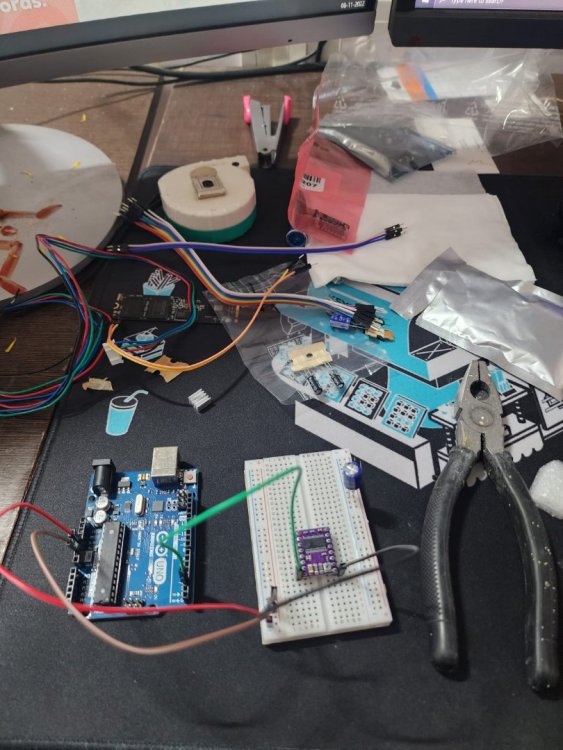

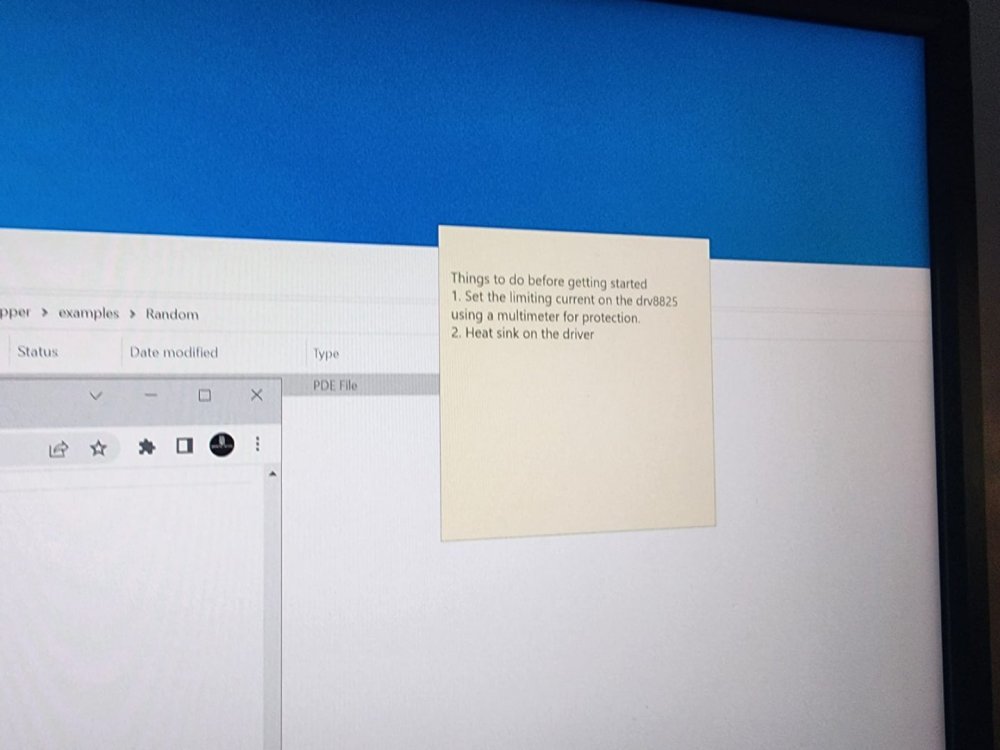

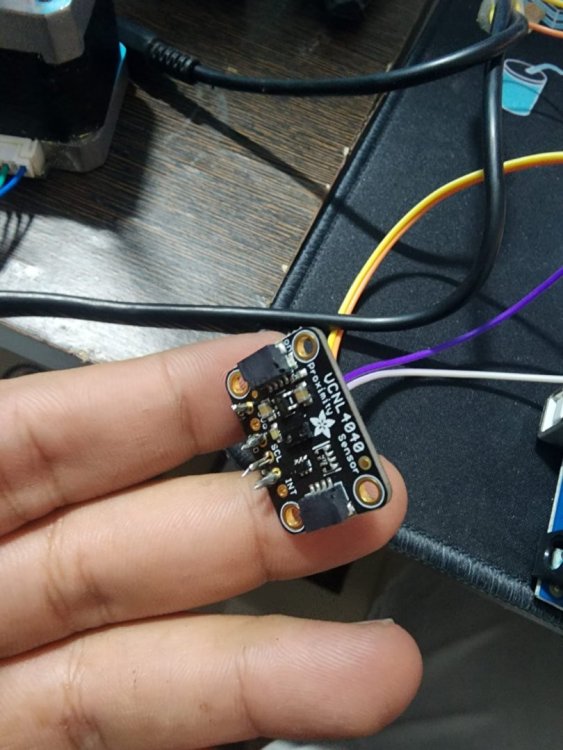

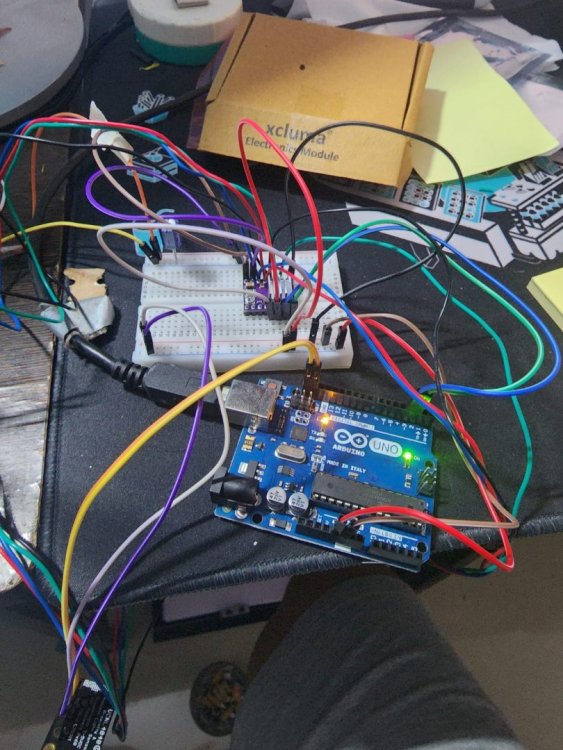

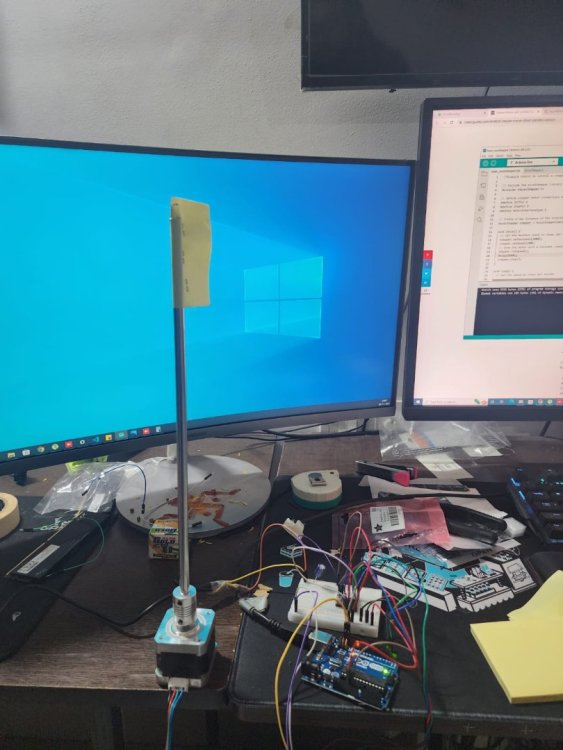

i will be using Arduino Uno 3 and proximity sensor to Open the acrylic panels on the front.

stepper motor needs a driver to set position and speed of the steps. testing things out with breadboard,

.thumb.jpeg.8e29ebf300c27454ea394ab0696decac.jpeg)

.thumb.jpeg.4eb1fad71f4f5ea539aea181e6bb0f49.jpeg)

.thumb.jpeg.6475184b62dff4af249767ca51f89608.jpeg)

This will need some trial and error.

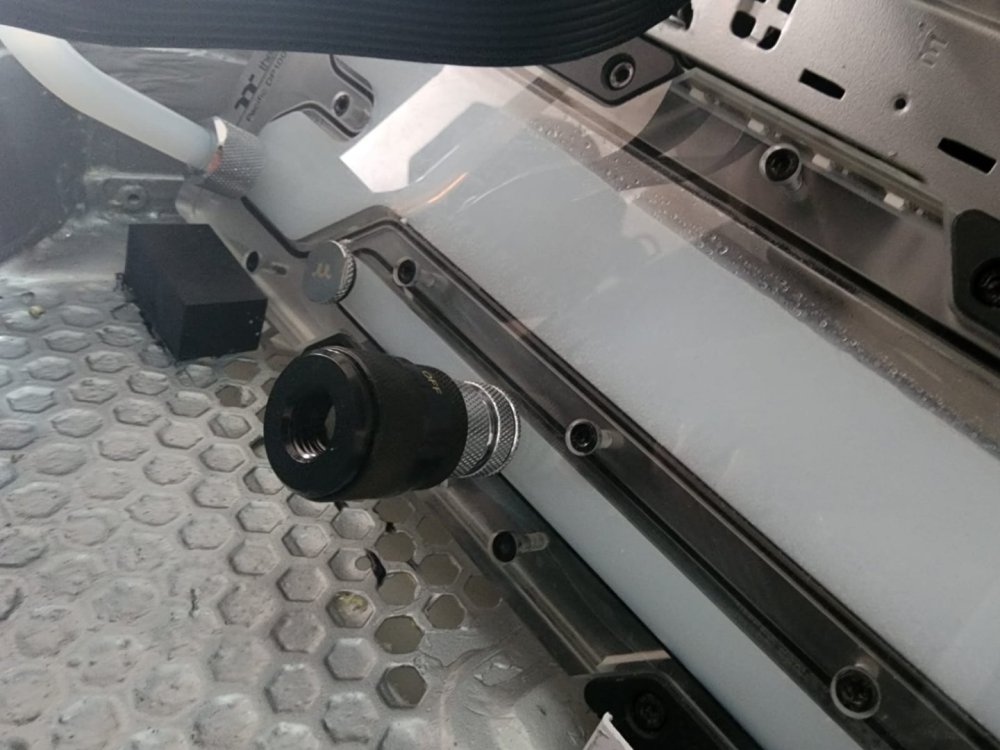

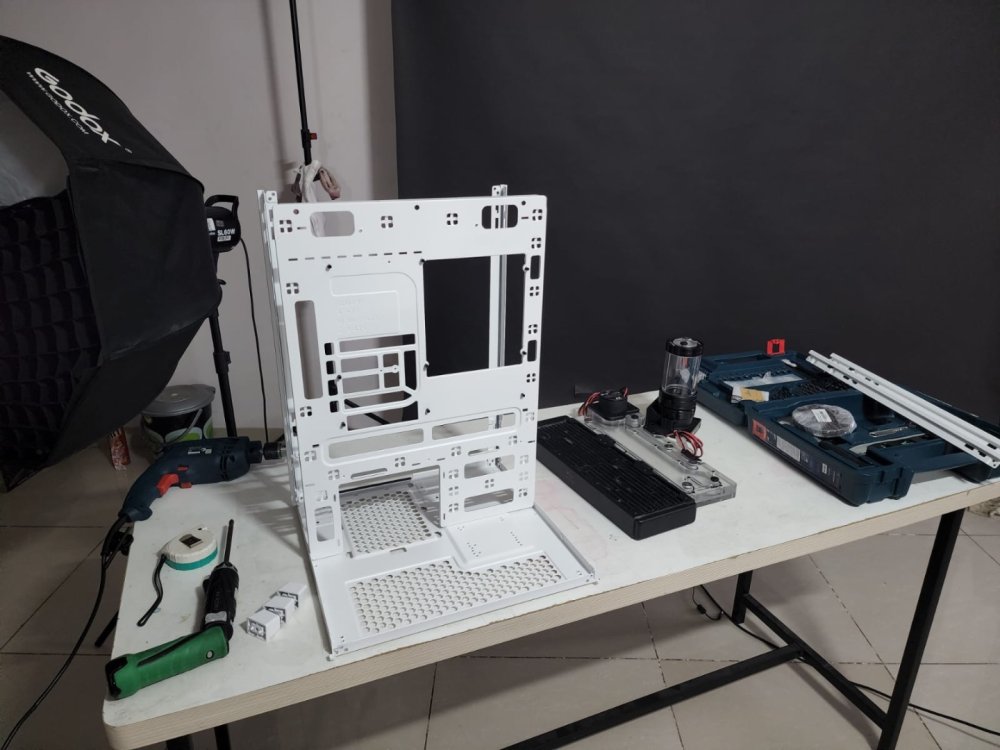

meanwhile i will assemble the machine and finish the CPU loop.

.thumb.jpeg.6566ce0e55e7f9679cc0837d92bd79e3.jpeg)

.thumb.jpeg.b71513a2806ae44ae53a34ad024596dd.jpeg)

.thumb.jpeg.df91ac29847b2908ea60e041d1265547.jpeg)

Aluminum panels are here as well test fitting with normal screws .

.thumb.jpeg.69921260eb8b062c2efcb0a44e72bac6.jpeg)

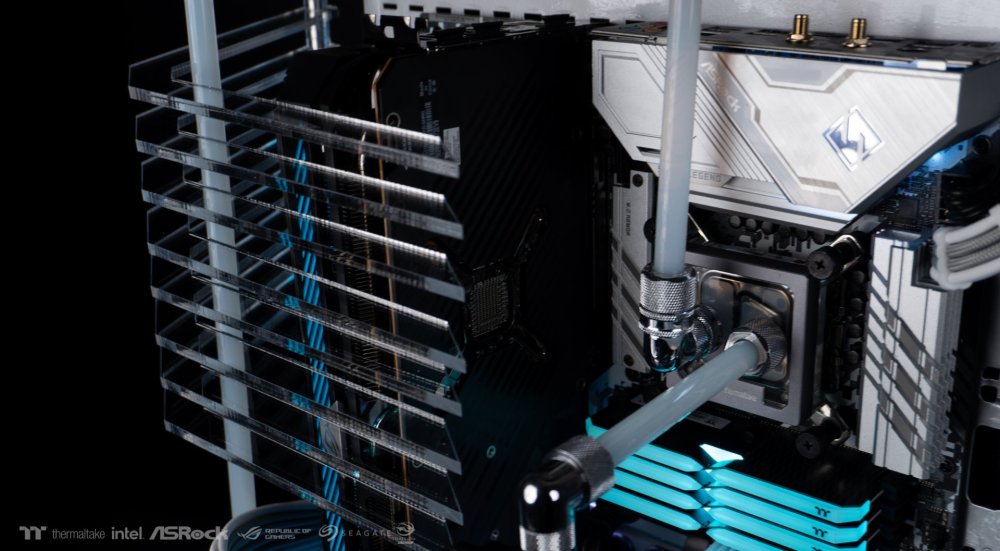

loop is complete, will start with test fitting of the Arduino first for the trial run.

.thumb.jpeg.e0949dd1c0fe49bfe77600df8df4eccf.jpeg)

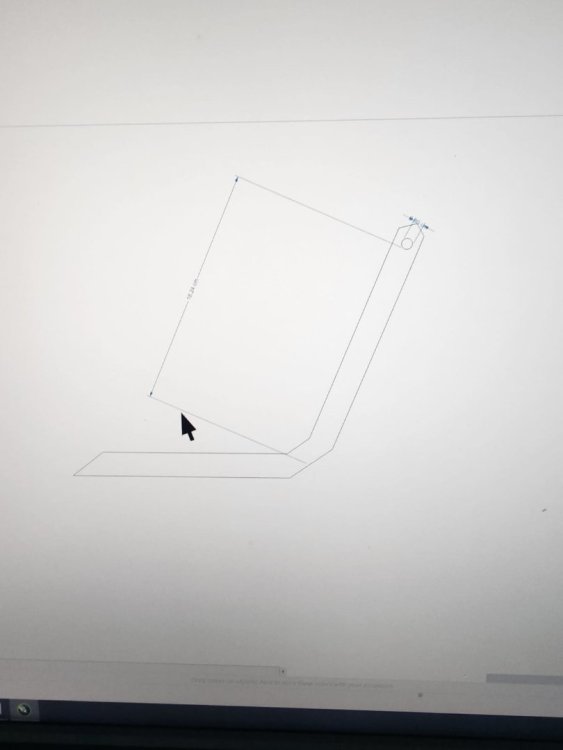

its working as expected , time for the acrylic panels . measuring out with the spare aluminum strip i had left ..thumb.jpeg.7c6b5b9fe3fd7fef345b96ef9434d584.jpeg)

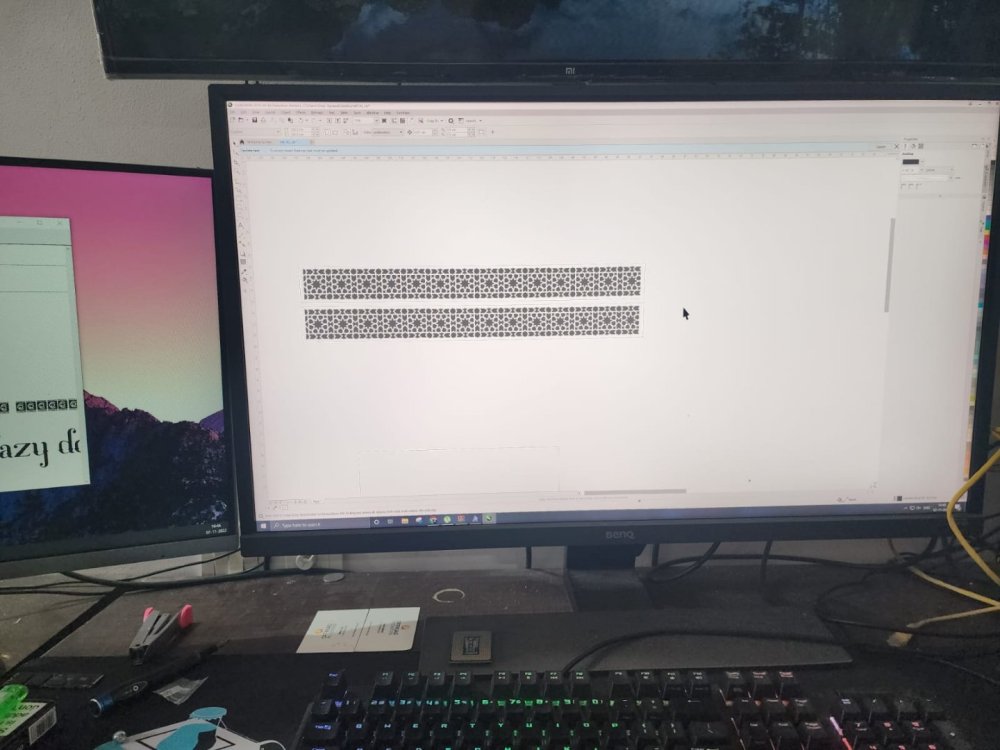

and the panels will be sent for laser cut. until i get the panels i will finish out the loop and installation in the build.

tested with distilled water.

and the leak test with liquid is done.

assembling the rest of the machine.

.thumb.jpeg.192be526ff92a65a6f1fdf8d9c5252ac.jpeg)

.thumb.jpeg.33f8fbc65c513968f64e00aec7cd447d.jpeg)

machine is assembled now its time for the coolant ,

.thumb.jpeg.80d865f00fd724c93cc0d6bc0ab5f7e7.jpeg)

after some TT RGB magic .

Acrylic panels are here as well .

.thumb.jpeg.b61af2e3ff0e243cba0d51769a7b54be.jpeg)

.thumb.jpeg.4c745dde02ff7a61546b719e63bf3cdb.jpeg)

Bottom Half Done !

acrylic still has the protection film on , that's why it looks milky.

-

removing micro overspray's and droplets with water paper 1000 grit.

.thumb.jpeg.abcdb2169dcf2d32f2e3ab88c3d82f83.jpeg)

now time for some rubbing compound and finish paste to rub out the fine imperfections.

.thumb.jpeg.908216b691940ae77bc1a0bc73e50853.jpeg)

.thumb.jpeg.200943691eb76c1ce988a8c12fad9225.jpeg)

.thumb.jpeg.1a0d0239e7cf0885e143fdbbc548889d.jpeg)

.thumb.jpeg.728f07d816a835529265c2ebaf4a4f06.jpeg)

top is also finished with a Matt Black Border , will be detailed later.

Looks good for the base , now it will be enclosed in 2MM aluminum sheets for the top and side .

now use of some vectors to order laser cuts of the design .

-

-

Sliced the trop panel into half will be making the front part transparent , will do the detailing ion the back part after the paint.

Now adding the Transparent acrylic in the front .

.thumb.jpeg.128f7bc544350d95d478e764590a2db7.jpeg)

pasting it with epoxy resin and some putty to smooth the surface ,

.thumb.jpeg.df4b90bf4a1e51dceeaa2c013dfb9dbd.jpeg)

sanding time again , after smoothing out the putty looks way better and uniform

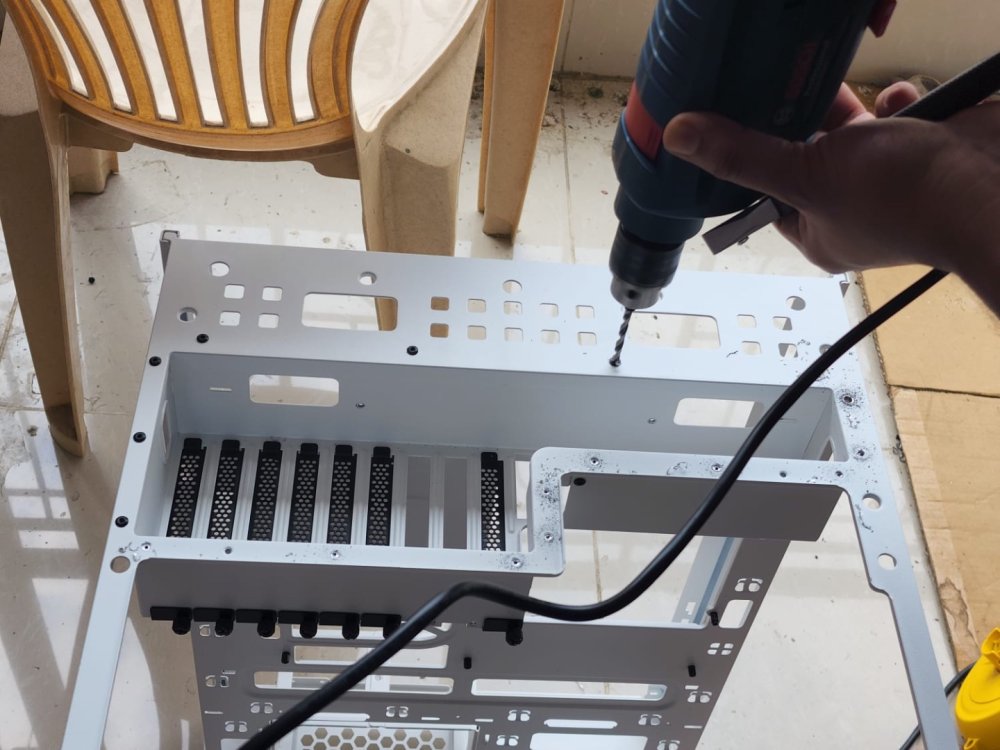

making holes for the Fan Cables.

.thumb.jpeg.06275c08c79828ce02c1e8b8ed230bd0.jpeg)

Smoothing out the whole chassis again before doing the paint job, and its ready for painting ,

.thumb.jpeg.74091959a8e634b4af7234a13f6bb17b.jpeg)

.thumb.jpeg.dbfe5c5d10ee9263f8c80c8471ac03db.jpeg)

Primer coat first , to get the unevenness out, looks good , came out as expected.

using spray gun and 2K paint , sliver is my color of choice for the build,

-

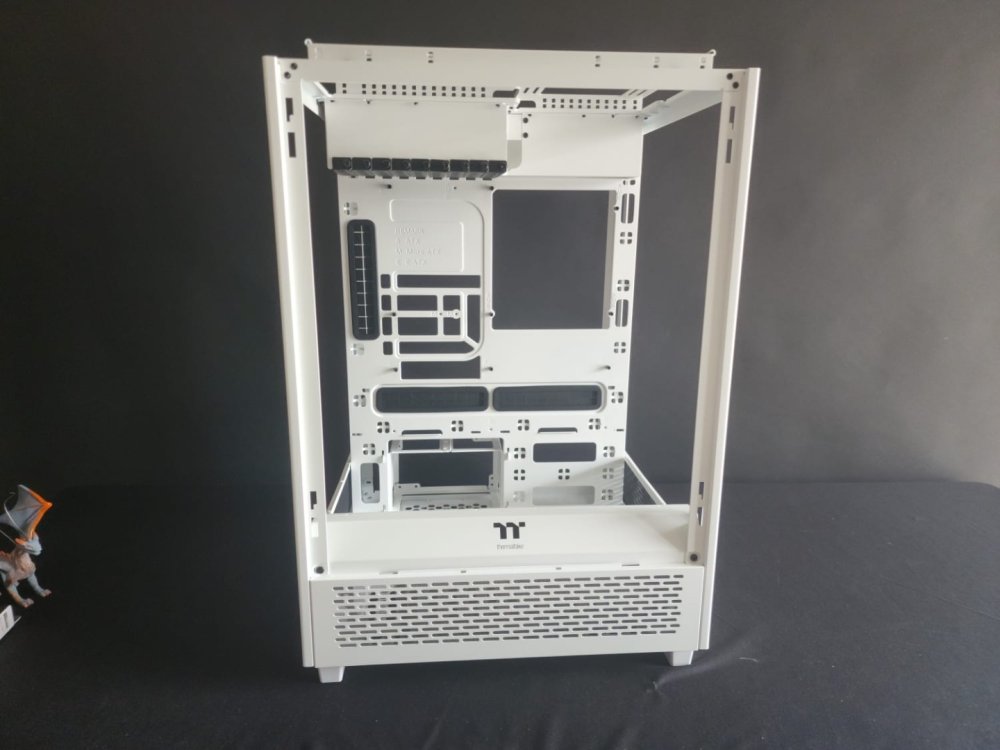

Now with Temporary screws i have completed the top shrouds and side Panels (where the rads will be )

1MM aluminium for the shorud and 2mm aluminium for the side panels

The top panel i will be dividing in two parts , one will be transparent and another will be the same default mesh.

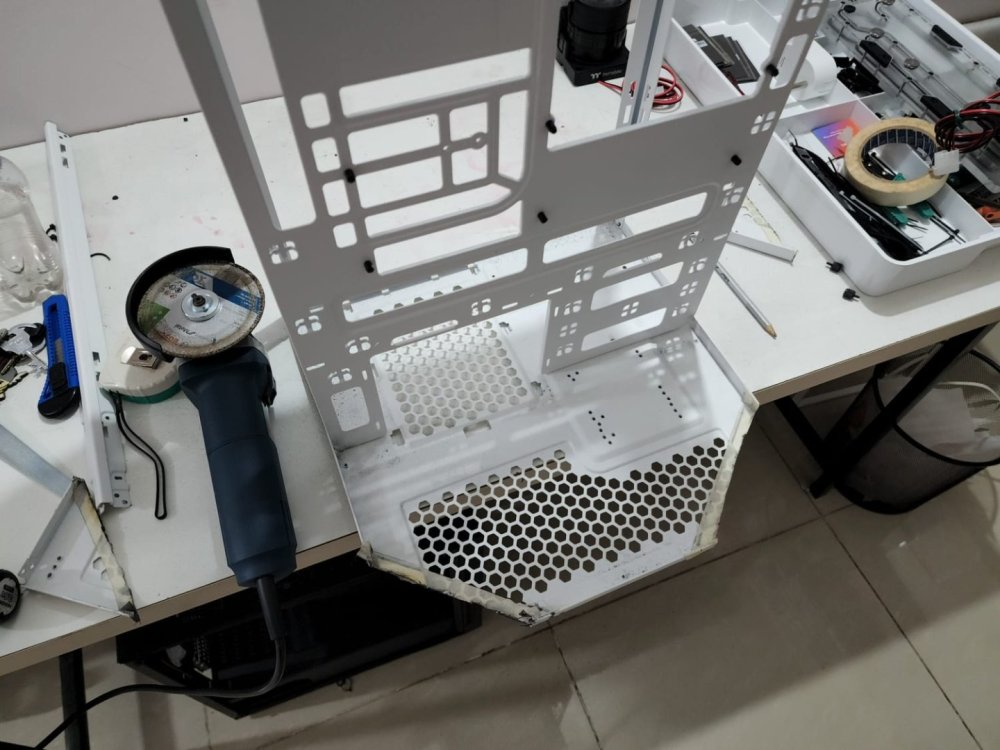

cuts and marking on both sides for Rad openings.

cuts and marking on both sides for Rad openings.

For the opening mechanism ibwill be using two 4.5Kg stepper motors which will be then controlled by arduino .

For the stepper motor brackets.

now with motor in place amd matkings done , let me test fit the fans and 360mm radiator

(Rad link )

Removing everything and getting started with Grey putti again to smooth out the joints on the panels.

Removing excess putty when its slightly firm.

Sanding it down for smoother finish

Dry sanding is more or less completed , getting started with wet sanding now.

with dry sanding , wet sanding, rad fittings in place , mod has started to take shape.

Also reused the bottom stands of the chassis and refitted them according to shape, much stable now.

-

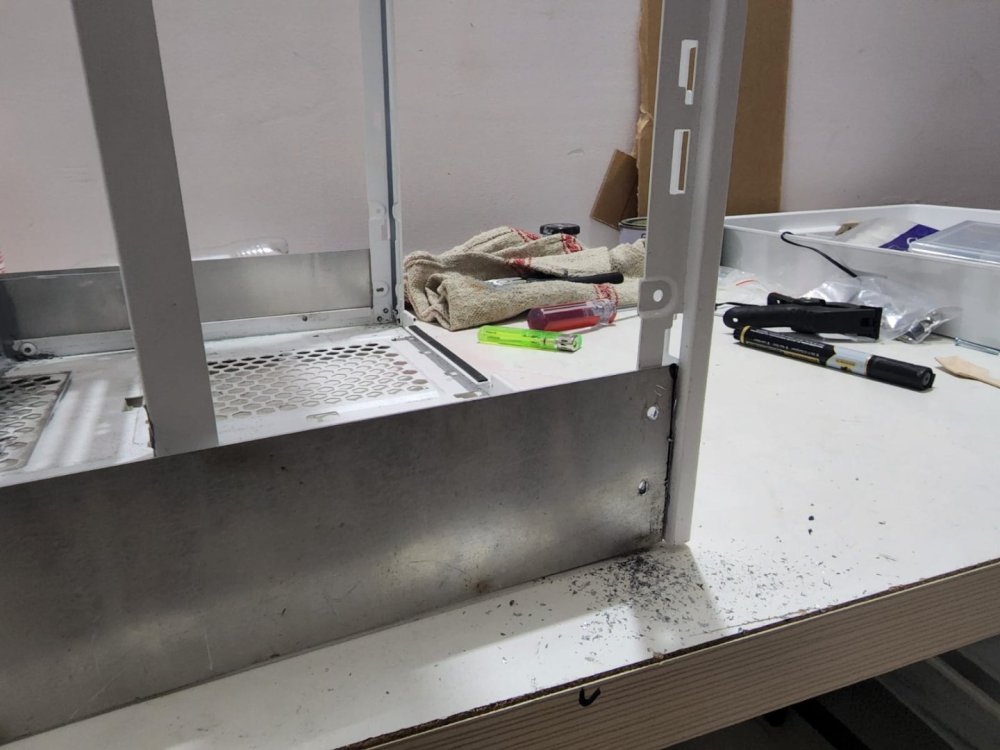

Now comes the part where i cover the base with aluminium sheet with 2 MM thickness

With hand bending the sharp bends will be little hard but we can try with more force.

First measurements with 1MM aluminium strip.

looks like perfect fit. Now lets gets to the final 2MM strip.

Bending with aluminium sheet.

final step is to get some screws for temporary fitting , i will fit rivets in the final step

final step is to get some screws for temporary fitting , i will fit rivets in the final step

-

-

23 hours ago, The_Crapman said:

Take care man. I've got a horrid cough from all the plaster dust in my house. Not nice.

you too man ! I shall continue once I start feeling better.

-

-

Down with Bronchitis , need to take a brake for 4-5 Days. 🤒

-

now getting to the structural supports, getting it into shape

some Grey Putti to shape the edges 🧱

meanwhile till the putty dries we can focus on the upper structure .

some more support

😄

😄

putty is dried for the bottom part.

-

- Andrew Makin and Yash Datir

-

2

2

-

- Andrew Makin and Yash Datir

-

2

2

-

- Yash Datir and Andrew Makin

-

2

2

-

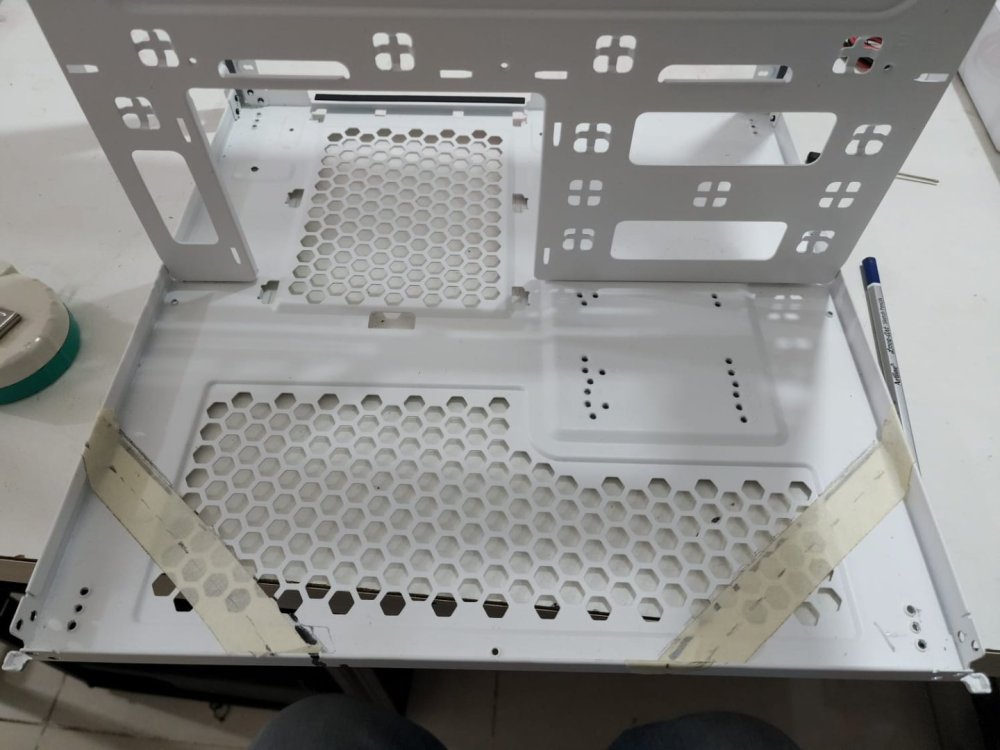

So the first thing i do is take apart the chassis , and readjust the Motherboard tray to fit my desired config.

i always want to make a mod which is practical in use and can be used in day to day life.

i will be trying to keep the Mod as practical to use as possible so it can be kept on a table for showcase and stuff.

- Yash Datir and Anil Malche

-

2

2

-

- Yash Datir and cheeselover

-

2

2

-

hey Boys,

I have received most of the parts yesterday ! lets get this started and make the best PCs out there !!

Myself Vinay Agrawal, currently working in the industry with my firm Gamerz Nation!

Best of luck to everyone! lets get this started!!

.thumb.jpeg.bb31b6b5a6b9d12cad4484c850347ff6.jpeg)

.thumb.jpeg.c6fc6ecc33ad519ab69131004ce72aad.jpeg)

.thumb.jpeg.97a306f6264986a3a758930e9b44972d.jpeg)

.thumb.jpg.0ef5cf8b0fbf4b9ceac1c736483df4be.jpg)

.thumb.jpeg.754c6750449007a19ca6094f09fb20c6.jpeg)

.thumb.jpeg.ac207fa0256dfc2046c683e26ee171bc.jpeg)

.thumb.jpeg.9ccad03bd8daafe452fd82639c7b125c.jpeg)

[India] Vinay Agrawal

in 2023 Thermaltake NeonMaker Lighting Mix Invitational Season 1

Posted

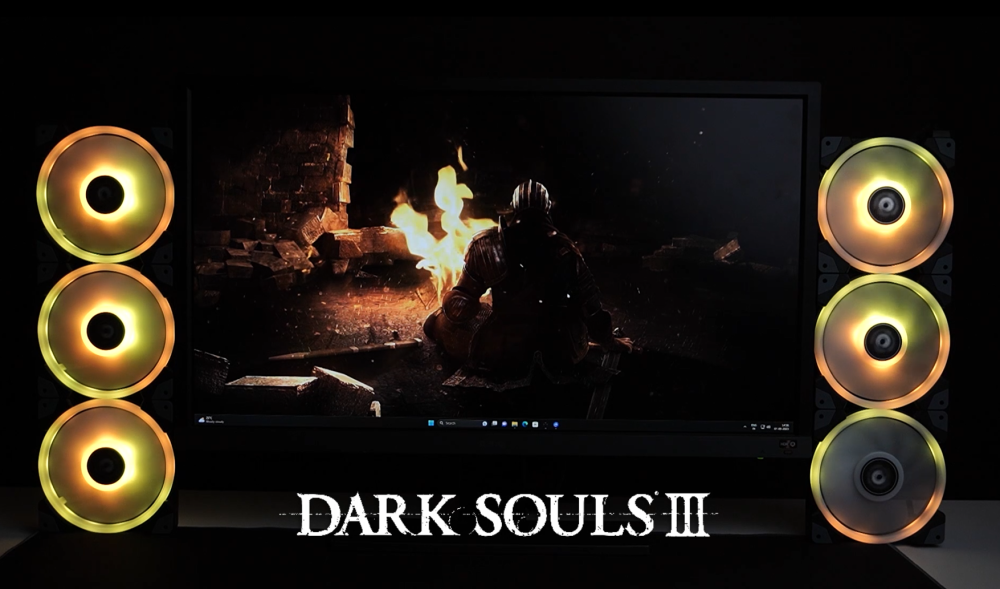

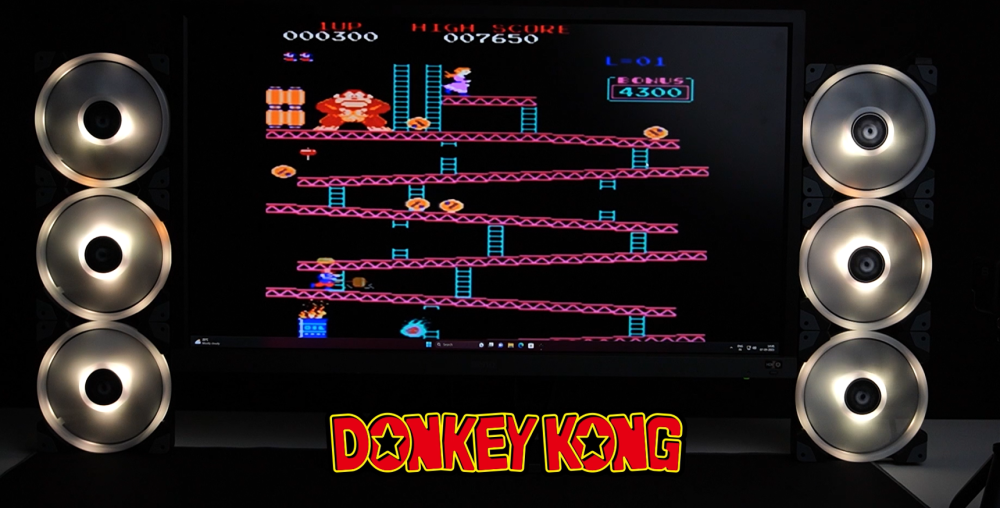

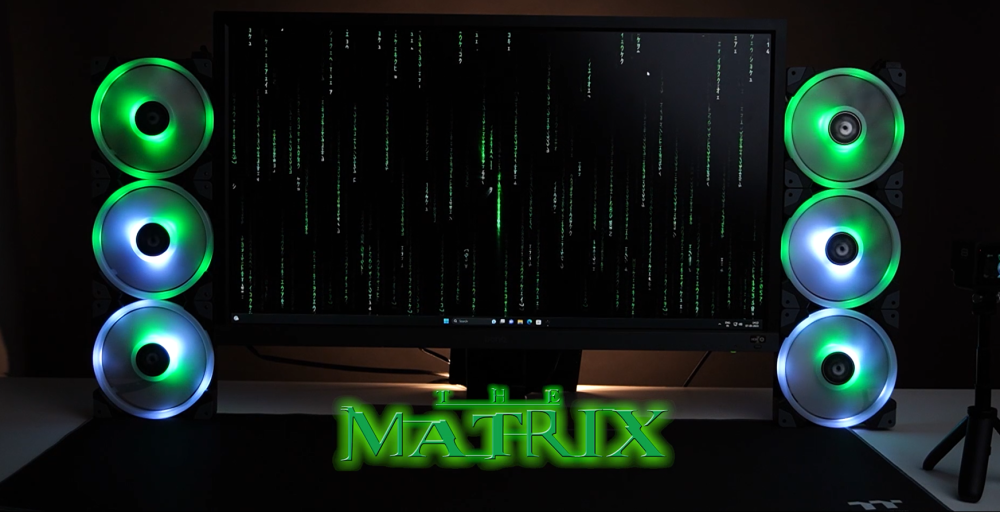

Here Is the link of the video for you to enjoy INTRO and Feel the profiles in motion !

Thank you ! Hope Everyone Likes it!

https://drive.google.com/file/d/1NeWT7kz7PLiUV4O6S3DS4H2MKYxJnp-d/view?usp=drive_link