-

Posts

39 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Downloads

Events

Gallery

Blogs

Posts posted by STUART_GGF

-

-

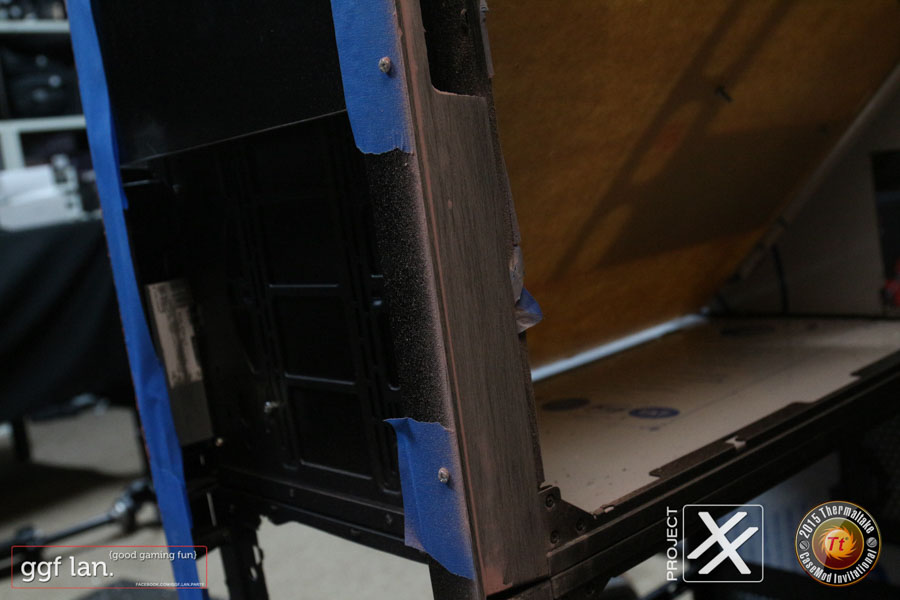

I also worked on priming the main chassis.

-

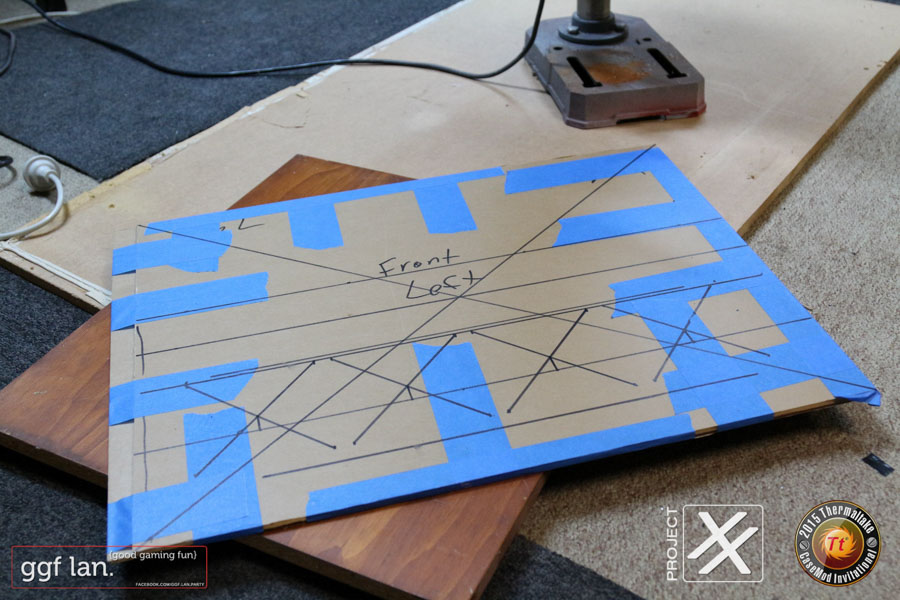

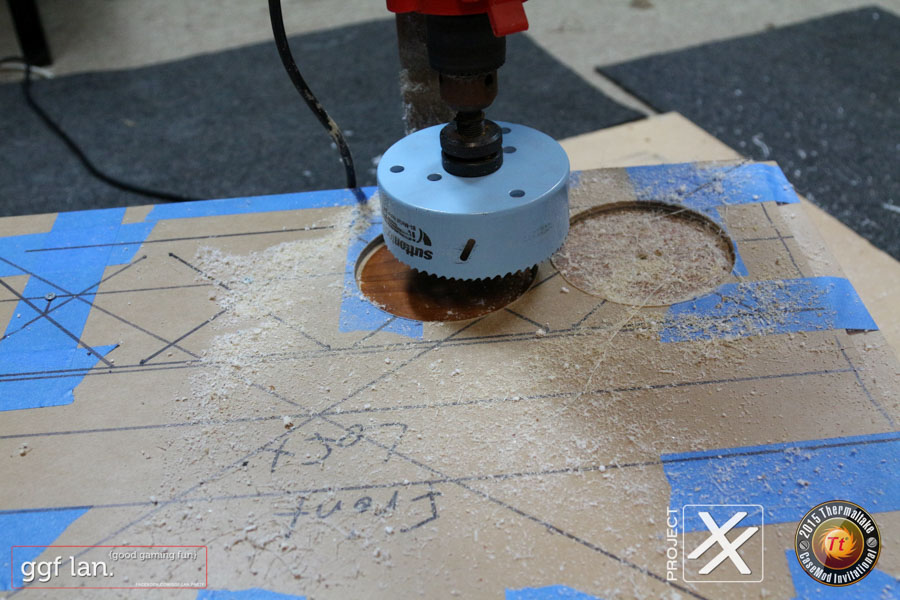

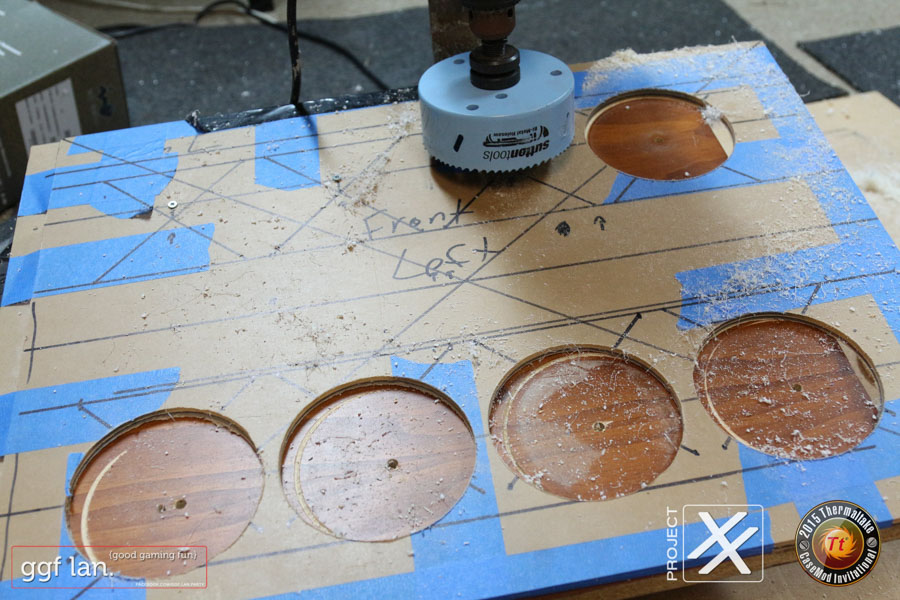

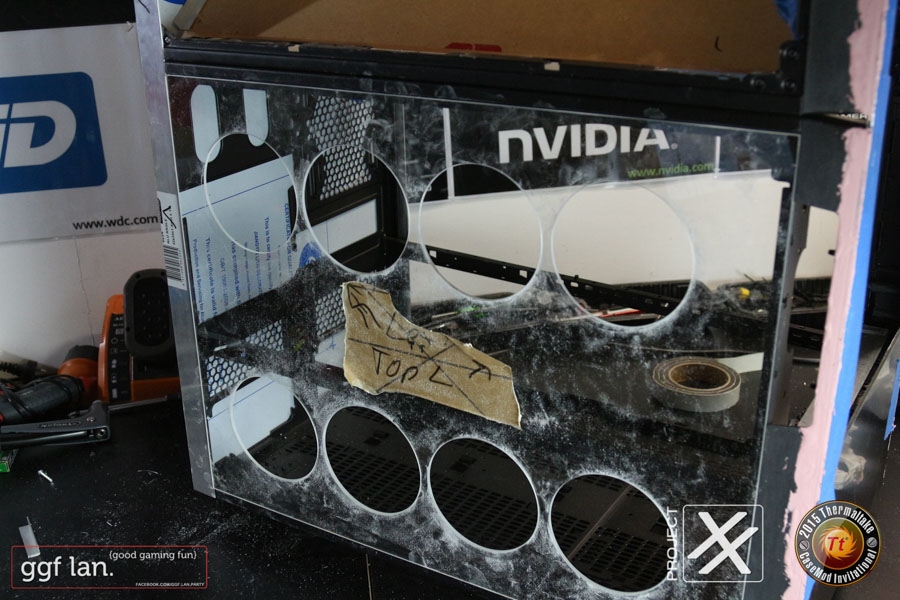

Another area I worked on where the two panels for the bottom X9, these needed to cover the 4x480 rads which would be inside this area.

Each panel had 8 holes in it so 16 holes all up. To speed the process up I temporarily joined the two panels to together so I only had to drill 8 holes

The two panels together

all holes done and sanded down to 80 grit.

Now moving over to 400 grit

Final shot of the panels. Here's one on the left side. Now these are clear atm but will be painted. I just use clear because it's more versatile

-

Next part I worked on was cleaning up the edge around the sides. For this I just used alum strips and tapped holes. I also picked up some real nice screws using M4 thread to finish it off

\\

\\

-

Alrighty. Had a few days off work so time for some more updates.

I noticed that once stacking two X9s there's a heap of unused space at the front. Perfect for a 24" 1080p touchscreen

I started by just cutting a large hole in the stock mesh front then the plan was to cover the whole area with a nice flat sheet.

Shot of the panel

When it comes down to cutting large lengths that need to be 100% perfect. I use a circular saw and a straight edge.

Once I had the top panel cut out perfect I then moved on to making a flush fit.

I also noticed that there was a slight join you'd see between the two panels

So I decided to get a filler and mask the two together

Once dry I began sanding it flat

Once fully sanded it was ready for the primer coat

Then after that the final satin white coat was applied

And a final test fit of the screen before securing it

Currently as of this post the screen is mounted and the 2 part bond is still drying.

-

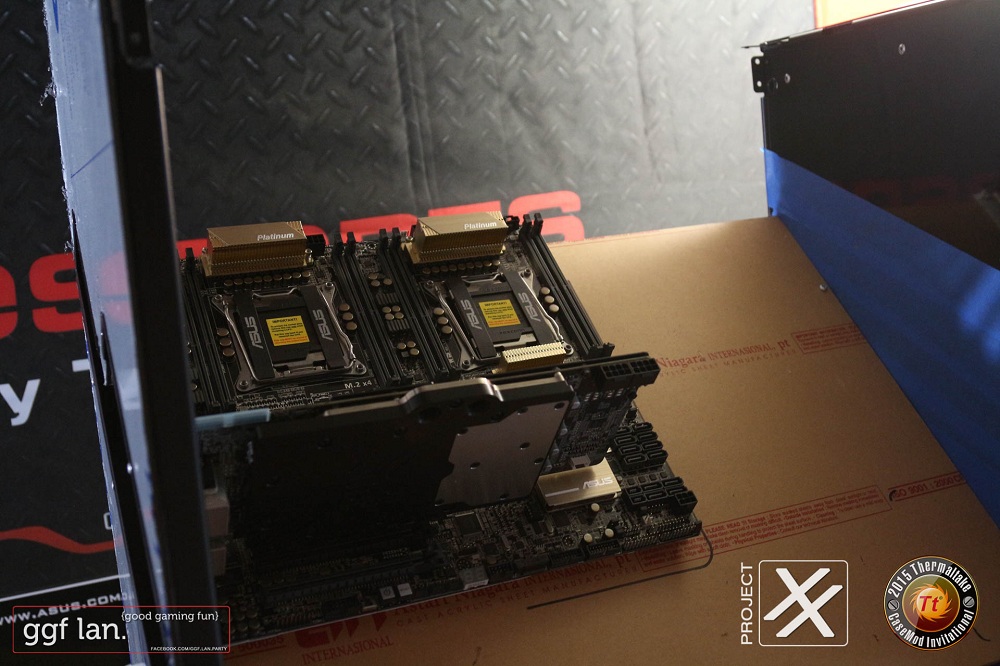

Now it's time to test with the final ASUS motherboard. Don't really want to keep this board around here for too long

- Orel Hardy and modguru

-

2

2

-

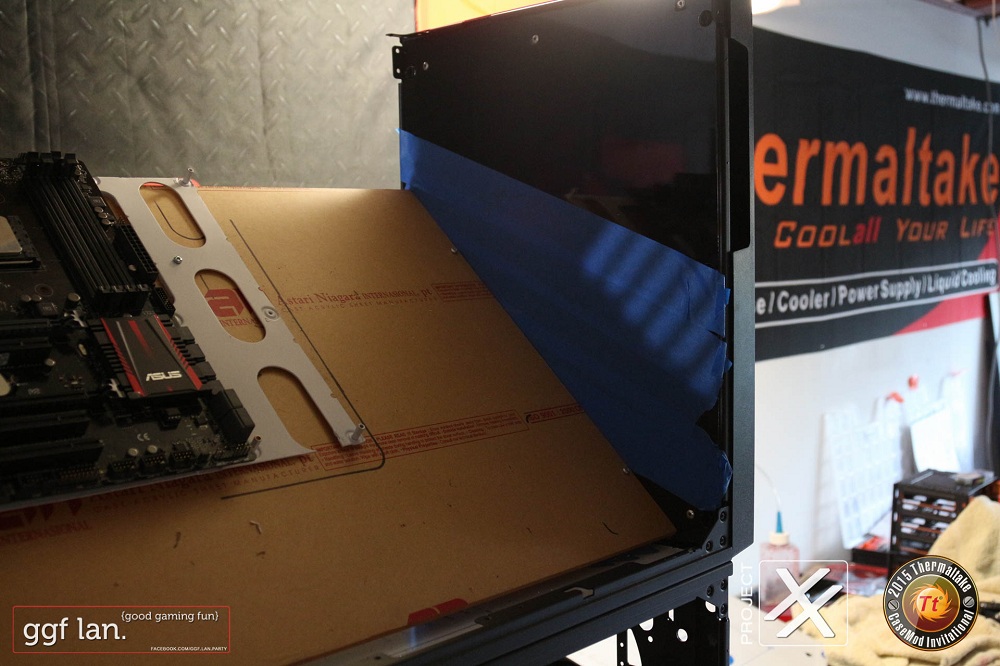

Now it's time to work on the mounting for the acrylic plate. I just went a simple way with 2 angle bits of aluminium. I also added a bit of the black alu composite on the inside of the front of the case. This just made it a a nice flat mounting surface for the bracket. I'll most likely paint this later on.

Mounting the bracket on the other side was pretty much the same.

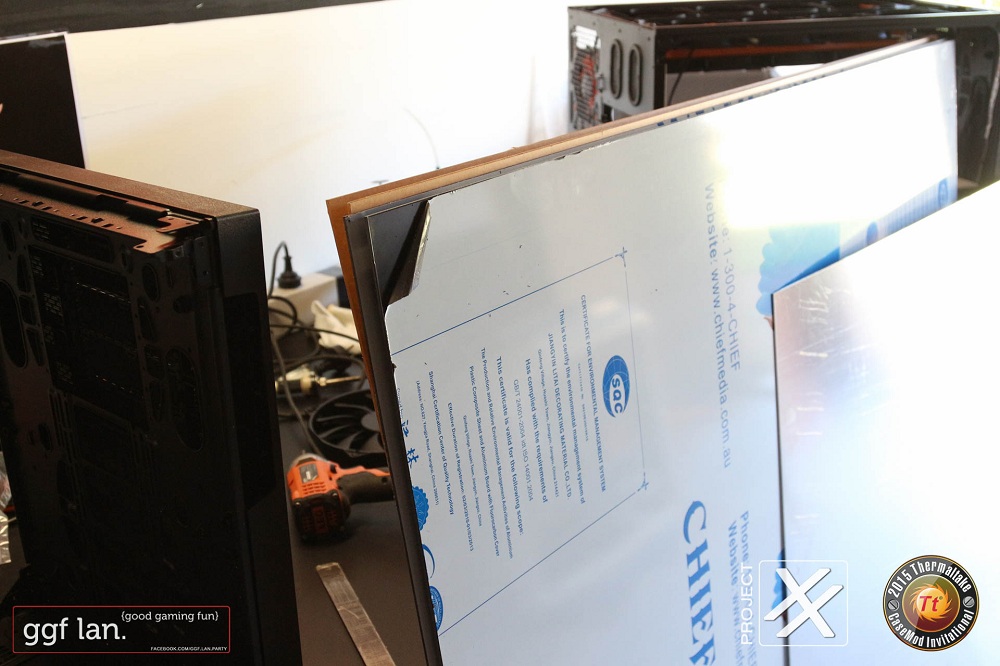

Acrylic sheet fits in nicely.

Testing out a motherboard.

-

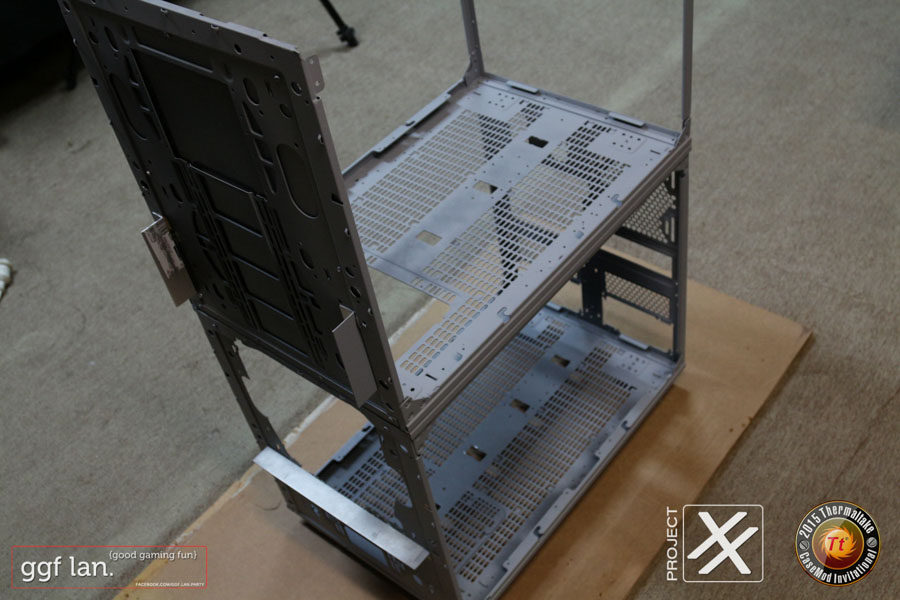

My first task with this build was to strip down most of the top X9 and work out how I'm going to do the angled motherboard. I also wanted to use a clear motherboard based to give it a floating affect. I also pinched the IO back panel from my Cosmos 2 to make it a bit easier.

Now the top sheet hanging off is way to long. But I'm just leaving that there for now until I decided exactly where I need to cut it.

-

Alrighty, time to get my modding on. Picked up some supplies. Lets see what we have.

Was keen to try some new materials for this mod so I grabbed some aluminium composite sheets. This stuff so far seems great. Very strong, very light and great to work with. It has a 1mm alu sheet each side with about 2mm of Polyethylene sandwiched in the middle.

I also grabbed a stranded 2mm aluminium sheet and a sheet of 3mm clear acrylic.

I got these sheets cut in half which gives me a few sizes around 1200x1200. Luckily I have a table saw out the back trim them down even further.

-

Cleaned out the garage to make room for an extra large work area. Pimped it out with some banners and it's good to go

- hotcoolman and ShadoWx3Sandy

-

2

2

-

Video covering the Toughpower Grand Platinum 1200W I'll be using in the build

- dO_ob, ShadoWx3Sandy and modguru

-

3

3

-

Some shots of the Toughpower Grand Platinum 1200W. man this thing is nice

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Motherboard shots

.jpg?date=2015-04-15%2014:38:15)

.jpg?date=2015-04-15%2014:39:12)

.jpg?date=2015-04-15%2014:39:31)

.jpg?date=2015-04-15%2014:39:51)

-

Here's a few shots of some of the gear so far.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-

Hi guys and welcome to my build log. My name is Stuart and I'm the owner of GGF. First off I'd like to thank Thermaltake for selecting me for this global invitational competition. Now lets jump in and see the wonderful sponsors who are supporting me in my Double X Project. Just a note to add that I'm still talking with unconfirmed sponsors and will add these up later.

Playing host to this competition. We aimed to keep everything Thermaltake as much as possible. This included the required Thermaltake gear including Case and Cooling. We also opted for Thermaltake PSU and Riing fans.

When it comes to Motherboards and Video Cards Asus is always our number one choice. The flexibility and endless support they provide make it that much easier to build customisations.

Having Asus on-board is only part of the process. With NVIDIA's support we wouldn't have the foundation for the video cards being used in the build.

A hardcore build needs hardcore memory. Avexir makes some of the best looking memory around. They are provided a HUGE 64GB Raiden kit for this project.

As SSDs are becoming the norm. Most people are forgetting the good old Hard Drive. We haven't forgot which is why we use hard drives in most of our builds. Including this one. WD also provide the largest range of drives for just about every purpose.

ModGuru are relatively new to the scene and we're happy to have them on-board. ModGuru are helping to supply LED strips and connectors for the build.

100% of this build is performed by me. Painting, cutting, drilling, all done in my house, either in the garage, backyard or shed. I'll be putting up a final write-up once the build is done with pictures of the tools used for my build. I feel the purpose of this project and competition is tell help close the gap between modders and beginners. I'll be showing you that you don't need thousands of dollars worth of high end equipment to do modding.

Other links to keep an eye on

Build Specs/Hardware - More info - click here

CPU/s - 2x Intel Xeon e5-2667s

Motherboard - ASUS Z9PE-D8 WS

Memory - 64GB Avexir Raiden

GPUs - 3x ASUS NVIDIA STRIX GTX 980's

SSDs - 3x Kingston HyperX

Storage (HDDs) 3 or 2 Western Digital 4TB Blacks

Power Supply - Thermaltake Toughpower Grand 1200W Platinum

Fans - Thermaltake Riing Fans x22

Water Cooling

Pacific VGA Bridge Triple x1Pacific V-GTX Block - STRIX - 980 x3Thermaltake Pacific W2 CPU Water Block x2Thermaltake Pacific PT40-D5 Silent Kit Reservoir/Pump Combo x2Thermaltake Pacific P1 Black D5 Pump w/ Silent Kit x2Thermaltake Hard tubes 500mm x10FittingsThermaltake Pacific G1/4 Stop Plug w/ O-Ring – Chrome x10Thermaltake Pacific G1/4 45 & 90 Degree Adapter – Chrome x10Thermaltake Pacific G1/4 90 Degree Adapter - Chrome x10Thermaltake Pacific G1/4 Y Adapter - Chrome x10Thermaltake Pacific G1/4 Female to Male 20mm Extender – Chrome x6Thermaltake Pacific G1/4 Female to Male 30mm Extender – Chrome x4Thermaltake Pacific G1/4 Hard Tube 16mm x30RadiatorsThermaltake Pacific RL480 x4I've created a dedicated website for this competition. This is to keep everything in one place. On the site you'll find videos, pictures, build info, build log and more. - www.ggflan.com/tt/

Other links to keep an eye on

- dO_ob, LiquidAtoR, ForSkinGump227 and 1 other

-

4

4

[Australia] Stuart Tonks

in 2015 Thermaltake CaseMOD Invitational

Posted

Moving on to the blocks. To fit the theme I painted the GPU and CPU blocks to match, and also the pump covers.

Also found the badge from my first ever TT case, the Xaser 2. Cleaned it up and will be using this on the front of the new build