Search the Community

Showing results for tags 'Reservoir'.

-

Hey guys. This is something I've been planning to do for nearly two years now, and it's finally coming to a head. As some of you may have seen, I recently put together a custom reservoir to sit in the window of a Thermaltake Core P5. You can find the thread detailing how that all happened here . So after much debate between choosing X299 or X399, I eventually opted for Threadripper. I wanted a build I was sure would continue to be supported for years to come, and I didn't feel that I could get that out of Intel (Plus I didn't want to delid). So here are the parts! I ordered these during one of Ebay's 20% off sales, so most of them were a pretty good deal. The parts are as follows: Threadripper 1950x Asus ROG Zenith Extreme Strix GTX 1080ti Gaming TeamGroup Vulcan ram (64gb 3000mhz) Samsung 250gb Evo M.2 SSD Thermaltake 850w DPS Titanium (Only PSU with theRiing fan and two EPS outlets) Some Riing fans for the radiator And of course, the Core P5. I'll be using some HDD's from my current computer when it's time to migrate to this one. The first thing I did was put everything together and test the system. I decided to shove the 1080ti straight into my current build and pull the R9 290x out of that one so I could enjoy those high refresh rates straight away. We have ignition! Windows was successfully installed! It was time to focus on the more aesthetic side of things. I figured, if I was going to put this much effort into this build, I may as well have a symbol/logo done up to match the PC's name. I contacted a graphic designer located in Queensland called Sam Johnston (He has a business page if anyone's interested. Would recommend). Within a week I had a fully-fledged logo! I'm lucky that at work we have a laser cutter on hand. Here I am testing a few different power levels before etching the window. And here's the real deal. I decided to etch it backwards so that it would retain the gloss from the front side of the window. And not long after. Here it is after a quick cleanup. And finally after a polish. Not long after this, my water cooling equipment arrived from Bitspower. All bar the pump mount, which I unfortunately forgot. Hello extra $35 shipping. I tell you what, I feel that Bitspowerdon't get the recognition they deserve. Look at the quality of these blocks. Opps, forgot to take a photo of these ones with the wrapping off. While the waterblocks were great, I did have an issue with the radiator. I find it unfortunate that Bitspower stopped producing the single-sided version of the 480 radiator, and have opted for a double-sided model only. This produced a problem when mounting it to the P5 as I'm sure you can clearly see here. The Core P5 is flat on the side I need to mount the radiator to. But I had a solution in mind. Little bit of silicone and they were sitting pretty. Just shove em in. And wipe the excess away! Now I do love Bitspower, but one thing that irks me about them is the fact that all their plexi products have a frosted finish. I much prefer how EK does this with their crystal clear blocks. Thankfully, polishing acrylic isn't something that's particularly difficult. Before: And after: Before: And after: Before: And after: This was by far the worst part. I forgot to take photos of the ram blocks, but I did get a few before and after shots of the ram sticks themselves. At this stage, I ordered some cables fromCablemod. I quite like the scheme I came up with. They arrived not long after. Shortly thereafter, my pumps and liquid metal arrived. Naan Bread always looks at me like I've just asked her to hang out the washing.Unfortunately I didn't order enough sleeving. I sleeved up one of the pumps, but had to order more sleeving for the other. I couldn't find anyone selling Alphacord in Australia, so I opted for a knock-off vinyl sleeve from eBay. It was not good. I'll post photos of that later, but it looks like I'll have to order more Alphacord from overseas. Money money Next up was attaching the monoblock to the motherboard. Not a bad idea, Asus. Liquid metal is awfully pretty. And hard to figure out how to apply for someone who's never used it before. I got there eventually. And that's where I'm up to for now! Looks pretty good I reckon. I've got a few more parts on the way. Not much more I can do for now until they arrive.

-

Hello, Does anyone know if its possible to replace the res that comes with the Thermaltake pr22-d5 pumps? I currently have a 300ml version but need to replace it with a 200ml for it to fit in the build i am doing. Would the T11 200ml reservoirs that thermaltake sells be mountable on the pr22-d5?

-

Hi guys. My first post here so I thought I'd make it a good one. It's been a dream of mine to build a reservoir and integrate it into the window of a case for some time. I initially went down the path of having someone else (A very well known custom PC builder with a huge Youtube presence) do all of the design work and production for me, but after waiting nine months with no communication from them except to sometimes reply to an email giving me excuses as to why we'd blown out the initial six-week timeframe, I decided to do it myself. Here is where it all started. This was done up in paint hastily as a way to try and visualise what I was going for. Now, I have some design experience and could have done the next step myself, but as a high school teacher I rarely find the time and since we were in the middle of marking season, I decided to outsource the designing to a fantastic case modder in Italy, FlowMods. He was absolutely fantastic, and offered me a more than reasonable price. From top to bottom it measures at 570mm. Go measure that. YOU SEE THAT?! That's absolutely huge! So, now I had to source the case and acrylic block for machining. The block itself was actually quite cheap, but the shipping. Good lord. It was more than the #### block! And yet, it was still the cheapest option I had. From Sydney to Canberra it cost me $57 to ship it. The block itself was only $45. Here it is, and where it'll be sitting on the case window. My next job was to find a CNC shop with the equipment to machine acrylic this size. I eventually came across a shop called "Devilish Racing", who despite the name mostly built custom equipment for the Australian Defence Force. Naturally, Defence work took priority, so after about two and a half months I dropped by and picked up the freshly machined reservoir, threaded for M4 bolts to hold it to the window and G1/4 for the water cooling connections. He even cut the holes in the window for me, which was nice of him. So that was the easy part. Next came the polishing. This stage took about six hours in total. I needed a few things. 600 and 1200 grit sandpaper. Kerosene. Most people wet sand acrylic with water, but kerosene is more viscous than water, so I drowned my sandpaper in that instead. A drill and polishing attachments (Reasonably cheap). Brasso. WD-40. Plastx headlight polish. FW1 cleaning wax. As you can see, the reservoir was quite cloudy from the CNC process. So my first step was to hit it with my kerosene drenched 600 grit sandpaper. This took about an hour. As you can see, it looks much clearer already. Next step, 1200 grit sandpaper and even more kerosene. Another hour :'( The improvement was a bit harder to see this time, but it felt MUCH smoother. After this came the brasso and drill polishing kit. Thankfully this was nowhere near as physically taxing as the sanding and significantly faster. So it looks much clearer now. Brasso is fantastic stuff and was recommended to me by Ross at Devilish Racing (the CNC shop that produced the reservoir). The only problem was that it gunked up the threads. This was something I would have to deal with a little later on. So, this is where I used the Plastx. The reservoir was much clearer already, but still cloudy in some areas, especially those the polishing attachments couldn't reach. I neglected to take a photo of the reservoir immediately after hitting it with the Plastx, but you can see the impact it had in this photo where I'm cleaning out the threads with WD-40. So I found that even though I was doing this part by hand, I couldn't quite clear up the internal corners. I grabbed my Dremel kit and attached the small polishing tools to finish that job. Something I once again forgot to take a photo of. But here is the reservoir after, about to get another hit from some Plastx. As you can see, it's already very clean at this point. Following this, I gave it a final polish with some FW1 cleaning wax. Naturally, I only applied this to the outside. You don't want wax residue flowing through your loop. Here she is, looking crystal clean. Polishing is now complete, thank ####. So with the polishing out of the way I now had to measure and cut the O-Ring cord to fit. Please ignore my pyjamas. You can usually use superglue for this bit, but I opted for an O-Ring connecting specific glue (Sureloc SL406 Cyanoacrylate). Here it is fused together. Looks good, hey? Nearly done now. The first step of sealing it up was to bolt down a select few of the screws so that everything was lined up. This is the part where I had to be most careful. If I overtightened a single bolt, the entire thing would be ruined. I set my electric screwdriver to its lowest torque setting so that at the slightest touch of resistance it would automatically stop. I lightly tightened each bolt three times after they had been fully inserted so ensure that there would be no leaks. I cannot stress enough how careful you have to be here. As soon as you feel resistance, move on and come back around to it. After tightening every single bolt in the first pass I found that the bolts I'd first done now needed additional tightening. Here it is all fastened and ready to begin filling for the leak test. SUCCESS! Here she is! Finished at last.

-

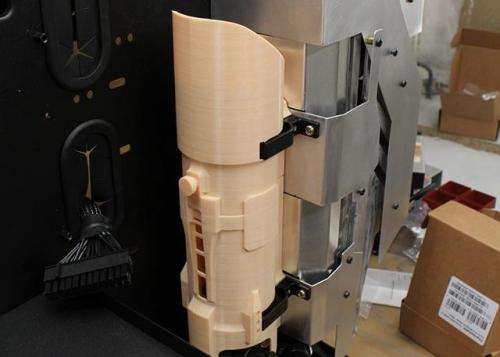

Thanks for Gizmo2poche's 3D Design sharing! Name: Gizmo2poche Description: 3D printing parts that could be assembled together to obtain a riflescope on Pacific R22 reservoir. The first part to engage has to be placed on the core of the reservoir without the transparent cylinder The second part has to be place on the top of the riflescope, it could be translate to the extremity of the transparent tank until to be stop by the black hood to let a clearance. This clearance will be useful to screw the top on the core. Like this, you can assemble the two parts to put them together and lock the 3D printing parts between the extremities. Share your ideas now! http://3dmakers.thermaltake.com/downloadMaker.aspx