-

Posts

50 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Forums

Downloads

Events

Gallery

Blogs

Everything posted by Andrew Makin

-

Final Voting Starts Now!

Andrew Makin replied to TT_James's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Amazing work guys. Devastated my poor excuse for a body continues to stop me working at every turn. 😢 My vote is for Sam, just love the concept and the execution is flawless 💜 -

[Philippines] Samuel Callanta

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

So frickin cool man. Love it! -

[Thailand] Krittanon Kidprasert

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Man that's just so good. Superb! -

[India] Vinay Agrawal

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

That looks fantastic 😃 -

[The USA] Tristin Pivnick

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Turned out great 👍 Can here the 'pling-pling-plinh' of collecting the rings 😅 -

[India] Vinay Agrawal

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

This is looking great 😃 -

[Thailand] Krittanon Kidprasert

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Incredible work 💜 -

[United Kingdom] Andrew Makin

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Only the 3 months later than scheduled, but enjoy this intro video for the competition -

[Thailand] Krittanon Kidprasert

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Oh wow. That's quite the design concept. Looking forward to seeing this come together. -

[Philippines] Samuel Callanta

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Looks awesome so far 👌 -

[India] Vinay Agrawal

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Take care man. I've got a horrid cough from all the plaster dust in my house. Not nice. -

[Philippines] Samuel Callanta

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Great work 😃 -

[South Korea] Jony Cho

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Wow, this is looking amazing! -

[United Kingdom] Andrew Makin

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Ahoy hoy modderinos! Firstly I'd like to apologise to Thermaltake and the other sponsors for the total lack of progress. Life has not been kind to me the last few months; there has been a dislocated shoulder, a broken rib and house renovations that have see long delays leaving very little room in my house for anything. Thank you to Thermaltake for being so understanding and their continued support. Parts have most definitely arrived, even if they're still in the boxes they shipped in, trapped behind half a kitchen. 😅 The Tower 500 looks to be an absolute beast! This is Ralph, my little build buddy. He was especially grateful for the lovely new beds for him to sleep on. Even preferred to his cushioned tent bed 😺 I haven't been completely idle though. While my office was clogged with half a kitchen, I thought I should survey my shed, where the bulk of the modding would be done. It was not good 😬 First job then was to throw out all the rubbish and give it a bit of a clean. A few of the old cabinets from my now destroyed kitchen would make for great storage in here too. The shed was got 2nd hand, and put together by me and a couple of brothers when we were all hungover, so it hadn't exactly been done square and true. The back wall slopes quite a bit and all the rain water caught by the roof runs down it causing a fair bit of damp, so I curred that with a large sheet of tarp that you can see just poking it's head up in the last photo. There were also sizeable panel gaps in some of the corners that would need fixing. It was quite tricky, but using a sturdy screw and a c-clamp i was able to pull them tighter. I then sealed up any remaining gap and holes elsewhere with some silicone sealant. See that fail insulation on the floor? It was attempting to carry 2 of those home that caused the dislocated shoulder. 😂 By the time my shoulder recovered we were well into the heatwave that hit this summer. Good job then that this foil insulation also works to reflect radiant heat back out, keeping the temperature cooler than would otherwise be in a black felt roofed sweat-pit of a shed. With the first strip glued to the ceiling I sat back to admire my work, then went inside for lunch. When I came back and walked under the foil i was hit with a wave of heat. What the ####!? isn't this supposed to reflect it? Lets check fitting instructions..... Oh. You're supposed to fix it an inch or 2 away from the walls and roof. Sticking it with contact adhesive direct to the panels made it into a massive aluminium heatsink. Brilliant 🙄🤦♂️ So off that came and I set about fitting it properly. Getting the foil between tensioned evenly between the beams of the panels was such a pain. It was only right near the end when i found that using a small length of 25x30mm wood to get the gap right made it so much easier. If I did it again I'd do one span between beams per piece, rather than as continuous strip around. Especially when your shed is more crooked than the tower of pisa. I didn't take many pictures of the in-between stage and they're all pants anyway, so here's the finished article Suitable for modding and stopping aliens from ready your mind 😉 I was going to use the tongue and grove pine boards that had been removed from the kitchen ceiling for the ceiling of the shed, but it have a small kitchen and i was about 2/3 through the planks, but only covered 1/3 of the ceiling, so a different approach would be needed, so I ordered a load of sheets of 2.4m x 1.2m OSB Sadly, my trusty tape measure got stood on and broke and no amount of aluminium tape would fix it. It was the first tool i ever bought for myself 😧 RIP I also put some studwork in for where the sheet would end to screw the edges down, while also offering further bracing to the suspect structural integrity. Slowly but surely, the walls and ceiling all got cladded. The roof I was especially pleased with. I had been bit worried about the extra weight, but I got the panels fitting really tightly, requiring some not so gentle persuasion into place, which seems to have reinforced it if anything It was good progress. Just needed to sort some flooring out and get all the tools moved in and we'd be good to go. It had certainly been a tough day finishing off the ceiling, as you might tell from the state of my clothes. After I'd showered and changed, i slipped while wearing my slippers, landing chest first on the arm of my sofa, badly breaking a rib right on the bottom of my rib cage. This has had me out of action for about a month now, but have been feeling much better this last week. Should be getting on it next week when i have some annual leave booked. Goin to be a mad 2 weeks. As a not so subtle hint of what's to come, this mod will be called..... I'm sure you can work out what's it's goin to involve a lot of 🤔🤫 There has been some modding done though, here's a little sneak peak into the next update. So stay tuned Crapfans! Same Crap time, same Crap Channel. -

[United Kingdom] Andrew Makin

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

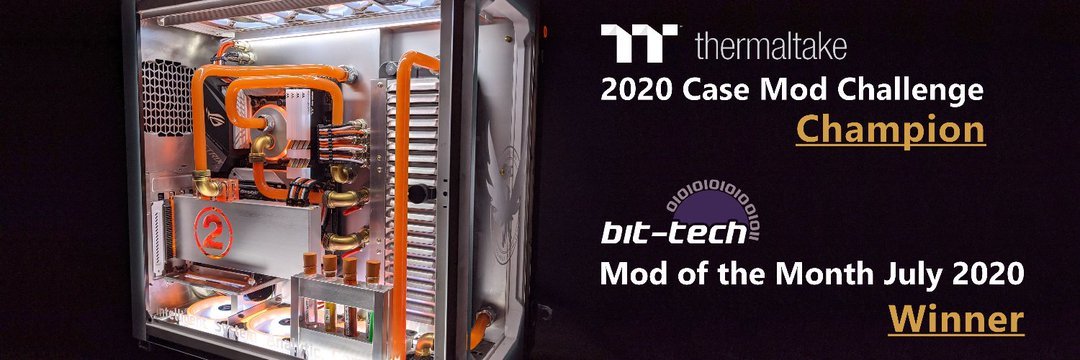

Hi Everyone. I'm Andy Makin, a.k.a The_Crapman/Crappy. It's an old university nickname, don't ask 😅 I won the Thermaltake UK 2020 Case Mod Challenge with my Division 2 themed mod Project: I.S.A.C. (Build Log) Project I.S.A.C. by The_Crapman I'm a former hardware reviewer for bit-tech.net and Custom PC, specialising in cooling and cases. I've been building PC's for over 20years and done watercooling and dabbled in minor mods for about 10 or so, but despite following the modding scene for a long time, ISAC was my first proper full on mod. To win the Thermaltake competition, as well as bit-tech mod of the month and get nominated for Mod of the Year was truly a dream come true. I really pushed myself with that first mod, doing things I'd never done before, and I'm going to continue that trend for this one. I'm no 3d modelling expert, nor am I all that good at hand drawn sketches, all my plans are rough sketches with tons of notes so I know what I was thinking later on 😅 Because of this I can't really share with you my plans, or what the mod will eventually look like, but expect metalwork. LOTS of metalwork 👨🏭 😉 Hopefully you'll join me on this chaotic adventure on what is definitely my most ambitious project to date. Even more so than that time I tried to take over the world with nothing but a wheel of brie and a pineapple 🤨 🤣 Good look to all the competitors. 🤝 -

I WON!!!!!!! 😲 😆 😂 😃 I still can't believe it. I've been in such a daze I even forgot to update you all. Thank you so so much to everyone who voted. Huge thanks to the sponsors for giving me this opportunity Thermaltake UK, Scan Computers UK, AMD, ASUS Republic of Gamers UK and Seagate. And a Massive thanks to everyone who's kept me sane these last few months. I really don't know what else to say. Other than thank you everyone. Hopefully I'll be back soon destroying something else with another mod. Until then Crapfans.....

-

Had some fantastic feedback and responces from both the PC crowd and from the division community in the last few weeks. Today though, today was something else. Should start at 16:04 To not only make the Agent Highlights on the State of the Game stream, but for Hamish to set it apart as something special is just, honestly mind blowing. Thank you to everyone who's voted so far, if you haven't already please go and vote, even if you like one of the other mods and vote for them, just go and vote! UK peoples can win the same case and PSU we used in the mods! Thanks. https://www.scan.co.uk/shops/thermaltake-modding-challenge

-

This was the start of the build, all the mods complete, it looks pretty messy but it's actually fairly organised, for me anyway. But this was the decent into sleep deprived madness. lol To prevent getting finger prints everywhere I tried wearing gloves, but when previously wearing them my hands get disgustingly sweaty, so I made some sweatbands from old socks 😂 First issue, I'd managed to damage one of the terminals in the CPU RGB extension, so I had to splice them into the controller cable. You can just see the squished terminal in the middle of the cables, took an age to figure out what the problem was as hadn't done anything with it since taking the demo rig apart 3 months ago. I thought it was the wrong connector and was trying to find ones that match up to either end before I realised what the problem was. After installing those bottom LED strips, the first and what should have been straight forward simple job was to get all the ancillary cables through the holes in the motherboard tray and get it attached. 4 hours. It took 4 hours to get the dam thing attached properly with all the cables through. The brass g1/8 fittings I was using for the LED cables should have been simply attached with a G1/8 nut that I'd bought. NOPE. The threads on the fittings were tapered and the nut didn't go up high enough to attached it securely to the tray. Joy. Rummage round in my box of crap, find a bag of smaller aviator connectors I'd bought and deemed too small, pinch the nuts which are a little oversized, but act great as washers. problem solved. It's a bit of a struggle getting the tray in position with all the cables on the lower right corner coming through and having them orientated properly, but I manage it. Start putting in the motherboard standoffs to connect it, get to the middle right one and there's a big gap that wont close properly. Very odd. Check everything over and find that my new washer solution for the fittings is too fat, hiting the original motherboard tray and stopping the new one attach properly. Everything off. Attach the fittings to the tray using cable ties, tied round the base to keep them in check. They don't form any part of structural integrity so as long as they stay put, sod it! Get the tray back on, get down to the bottom where I've drilled new holes to keep it steady and I've forgotten to attached the standoffs for them. 🤬 Back off then. Attach lower stand-offs. Attempt 4. Cables in the bottom left being SUCH a PITA, takes an age to get them to play ball so I can get the lower right corner attached. get down to the bottom left, it won't go on. There's an old screw thread that protrudes from the bottom of the case that it's snagged on and wont get past it without damaging something. I know it's there, I know I've got to slide the tray round it, but with the new lower standoffs the bottom edge of the tray wont go back as far and I haven't made sure it's not past it. back off. Attempt 5. Lower right cables again ****ing me off, big time, sworn into submission after an age. Get to the last mother board standoff in the bottom middle, it's out of alignment. Everything else exerting force on the tray has shifted it enough that I can't get the thread to catch and not end up at and angle. I remove a couple next to it and file it bigger, being careful at first, but gradually lose patience and hammer the er with a bigger file, vac up the dust. 4 hours after I started the motherboard tray is finally on. It should have taken 4 minutes, not 4 hours. But it's on. Can only get better from here, right? 🤨 Finally The case was ready for some actual components. Best get the motherboard ship shape with new thermal pads on the VRM and M.2 here you can see the additional detailing I did in the back, with some heavier streaks off the cable tie points and a very dirty bottom of the case, making it look like it's flowed to the drain hole. I also got the fans and verticle rad attached with the Thermaltake drainvalve underneath. Nice and simple..... Nice and simple until I realise I've left one of the temporary G1/4 port plug on the rad and it needs swapping for a proper one. I try just loosening the screws and swapping it without tasking it all off, but can't quite get it. I stop and think "you always try and do this, make 'less work' but ends up taking far longer, just take them off and do it properly." so I take the rad and fans off and swap the plug out. Can I get the rad and fans back on? Can I ########## I try the top fan first, I try the bottom fan first, I try the middle fan first! I can manage to get up to and half the screws in then just can't get it lined up for the rest. I JUST had this one, how is it not goin back on!!!??? Notice the rad is getting blocked a little by the drain port on the bottom, really weird seeing as how I attached that to the rad before installing it the first time. So I take that off, put a plug in it, it's still a real struggle to get them all on, but eventually I manage it. 1.5 hours later. ONE AND A HALF HOURS to put a rad and fan back where they had just been, but sans drain port. That is no where near fitting. Just does not compute??? Cursed I tell thee! But it's on, I get the motherboard on, looking good. Got the 3 brass fittings for the fan cables in, looking good. On the up from here. Or not. 🤬 I take the siding off the rad, screw the valve into the pass-through, go to put the panel back on, won't go on. It just won't, no matter how hard I try and something is getting broken in a minute. So have to take the rad and fans off. Again. Get the rad cover sorted eventually, Rad and fans go back on without putting up too much of a fight, but it's more time lost to complete lunacy. or more likely a total lack of sleep. lol With that sorted I can get to work on the loop. My 2nd ever bent piece of hardline. It's a bit of an odd one, the pipe has to go under the 24pin cable, then up, round and back into the CPU block. I had wanted that to be more of a continual curve, but it was much harder to heat up an area of the PETG evenly than I thought. I kind of botched my way into this piece that worked, so with time not being on my side would do. The heavens opened, bringing a bit a coolness to the air that was desperately needed. Both the weather and this cable tie point reflecting my mood at the time. Tired, battered, dejected. Gotta push on. Got this long run from the bottom corner to the res done in one go, pretty pleased with that. In this pic we can also see all the fan cable down the bottom. I'd taken the stock sleeving off ages ago, as it's massive, stiff and unyielding. The plan was to sleeve it with tinned copper braid. I'd got the braiding, had a test go with a bit of wire off another fan it seemed to go ok. I checked how long I'd need the wire, snipped the connector off and cut the wire to size as I had new terminals to crimp on the wire. But because by this point I'd had about 4 hours sleep in the last 72 and I was running out of motor skills, time and patience. I just could not get the wire through the braiding, It kept on snagging on this one bit and after getting past it, just couldn't feed the wire to move up through the braiding. I had to make a call and cull the braiding. At least I could still get all the cables cut to length and it would still look better than stock. So I took out the terminals and got to crimping, or at least I would have, but a combination of my tired decrepit postman pat hands and a crimping tool not suitable for such a small terminal just could not get it crimped properly. I ended up splicing the cable back into the connector I'd cut off. Quick test with a spare psu and controller confirmed it still worked, at least I hadn't killed it. I just had to forget it, 'cable manage' as best I could and push on. Time was desperately running out. And it did. No idea where the time went. I had a little trouble with the GPU bracket I think. That's another think that's got missed in the rush. I had to cut the back off the bracket having installed a new motherboard tray and removed about 10mm of space it used to occupy. This made it fairly flimsy, so I put a new screw hole on the back left edge and made a support bracket from 1/2" aluminium angle. The support bracket comprised of 1 piece attached to the bottom fan to keep it nice and solid, with 2 vertical struts bolted in tight that the original bracket would then rest on. No GPU sag here. 😁 I got a couple more runs done, had some trouble with the small run at the front because I didn't realise they weren't level. The run from CPU out to GPU in round the back was meant to just be a solid extension, but no combination of pieces I had fit properly. I tried so many combinations of 90s, 45s and extensions. I think one fit, just, but looked absolutely ridiculous as it used about a dozen different pieces. It was also too short for a small straight piece. I had decided to tray a 45 into a 90, but offset so the angle would probably be more like 30degrees and was beyond my mental capacity at that point. I was so tired and drained I could barely stand or talk. so I just crawled off to bed and left it. Failing terribly. Needless to say I had a fair old lie in the next morning. Had to take a few to wake up and my hands to loosen up before getting back on it. First thing I notice with refreshed eyes is the the weird CPU loop has got to go. Apart from just plain looking pants, it will interfere with the GPU out loop. An afternoon later and we're done. I think the only line I didn't redo in the front was the one round the back of the GPU. I'd figured a way of using tape to help mark where the bend had to start so that when I took it away there was no doubt where that bend was going. Everything tight, level and with some nice symmetry to the runs. That front run with the little level change was daunting, but I just heated a small spot, held the bend flat to the table and pulled the end up. Fit beautifully. I gave all the fittings, o-rings and tubes a good clean and tidied up the ends, made sure there was no rough or sharp edges and got rid of the tape marks. The tight bend in the back I also ended up doing by hand as it was tighter than any of angles offered on the mandrels. Took a few goes to get it right, but by jove we did it! The keen eyed of you will see the future in this picture 🤔 It's loop filling time! Non of that fancy air pressure nonsense, just good ol' fashioned tissue. Warning. The following video contains strong language and scenes of a disturbing nature. Yep, I'd left the rear drain valve open 😖 Good job it was pointing straight down next to the massive hole in the bottom of the case, so the majority of it flowed out onto the mat below and what remained inside didn't get very far or near anything shocking. After that little mishap it was plain sailing. Get it filled up no further problems, no leaks. :rock: I'd made the PSU a cagoule incase there were any "mishaps" in it's vicinity 😅 It was so close to being finished, I could feel it, like it was just over my shoulder. With no leaks overnight All the tissue could be done away with and the power cables installed. I hadn't been too sure about them until I got them in and caressed them into shape with the combs from the extension set we'd been given. Once in though, 😍 I installed all the rear cables, the top fans bracket with fans and LEDs and attached external panels, but of course forget to take any pics of that 🙄 Now we have to travel back in time, way back to the 13th July for the genesis of the next feature. 1000x600mm of 1" hole galvanised steel mesh, 6m of 37mm galvanised steel angle and a bunch of corner braces to make this beast a cage! First up was cutting the mesh to size. I started with the dremel but it was slow going as the wire was so thick. The hacksaw made quick work of it however and gave cleaner tighter cuts. Typically for me, the first piece I cut I cut the wrong size, meaning there wasn't enough to make the other 2 pieces the size I wanted. luckily I could just fit 2 pieces big enough in that would still work. Next up was to cut the steel angle to size, with angled cuts where 2 pieces would meet. This was jigsaw territory, made light work of the steel. Along the bottom edge of the cage I would only need one side of the angle and small lip to cover the mesh. This was done in 3 goes with the jigsaw, moving the clamps as the cut progressed. Soon had the 9 sections needed cut out Then I started to make the sides up, joining them with the corner braces. I marked up the braces with which angle they joined with and where. This would make sure there were no -ups come assembly time when all the holes were out of alignment. Coming together nicely. When there was crossover between 2 sides on the braces, I'd keep the first side built and connected so they would sit as they would in final form. I cut out one section of braces for the lower corners, to let it fit round the case. With all sides complete it was time to start figuring out the mesh attachment, with where the bolts could go through without fouling on the mesh and drilling out the holes. The mesh would be attached using 1.5-2" sections of the angle made from the offcuts. These were then drilled out with holes to match the main pieces (with mesh in place of course). These were all individually marked on both pieces so there was no mistaking what went there. With everything marked up the wazoo, there was nothing left top chance and it was time to construct. Nothing could go wro...... Oh, the bolts I've got aren't long enough. So with 32 pieces cut and 102 holes drilled that was as far as I could go. Fast forward 2 weeks and I had the new longer bolts, it was assembly time. This was done on the shed floor, which was so, so uncomfortable. Quite painful even. I'm not currently formatted for floor work. lol But he got built! And to even my surprise it was pretty darn sturdy 😃 Bit of JB Weld used as locktite and you could actually use it to keep things safe 😂 That was it. Everything was built. Everything was finished. All I had to do was put the cage on and.... it doesn't fit. 😞 I had done all my test fittings without the side window hinges on the case and they interfered with the back edge of the cage. I could probably have cut a couple of notches in it, but by this point I was at the end of my tether, so I lopped the entire back edge off. At least it now fit! ha ha Oh yeh and at some point I'd attached a staple loops to the top and front. another thing I forgot to document. There's probably more, but who knows? lol So that was it. I was finally finished. there had been some absolute nightmarish, soul destroying mishaps and moments in the last few days. I was so, so tired, my body was crying and I was emotionally drained. But at least it was finished and I could get on with the video. I had taken some pics with the case on when I first finished, but then realised the cage had red pen all over it. So had turned it off and given it a good clean before getting those pics above. I took the cage off and then thought "I should probably get some pics of the pc on with the clean cage". So I put the cage went back on, back on go the locks and.... Taking the key out of the last lock and the barrel just comes out with it. It just had to **** with me one last time. I was absolutely distraught. How am I going to get this off? Anything I do to cut it is just going to send shards of steel everywhere, I can't take the cage apart, it dam near killed me making it in the first place. Resigned to taking the cage apart, find I've built it too well and it's not going anywhere. Fall onto floor crying. Like i said at the beginning, it's been a difficult 2 years. lol Luckily a few folk here and elsewhere talked me down and helped me to the realisation that I could cover it up with something and cut carefully and I should be fine. So Here's the after shot. You get a good view of the staple and also the mesh I put in the top panel that i forgot to take any pics of or record in any way. I don't do rushed. lol And the cage and case survived! One last little snippet, the test tube contents. For those who don't know, The Division series is set in a time when a genetically engineered flu has been released. All the test tubes contain samples of things you'd find in the game. Fro Right to left: 1) Green Poison - the virus unleashed in New York on Black Friday using contaminated money, which is why it's also know as the 'Dollar Flu'. This isThermaltake P1000 pastel green coolant 2) E. Shaw's Blood Sample - Emeline Shaw is the head of one of the enemy factions know as The Outcasts. Emeline is an asymptomatic carrier and upon her downfall (at your hand), it is said that they can use a sample of her blood to help develop a cure. This is made from Paprika and water. 3) DC-62 - an anti-viral agent that was released in the worst contaminated areas, however in extreme cold temperatures, the DC-62 changed and became toxic and as deadly as the virus itself. These quarantined contaminated areas form the games 'Dark Zone' PvP areas. You sometimes get dust storms of DC-62 in the games weather patterns. This is made from dry turmeric, as the DC-62 in the game is also a powder 4) Anti-viral sample - in a secret underground lab in DC, scientists had been working on an anti-viral to combat the Green Poison. This was stolen by President Ellis and given to the Black Tusk, a paramilitary group trying to take over America, to whom he defects. You get back the sample of the anti-viral after defeating Milla "Wyvern" Radek at the end of the Black Tusks Styronghold mission 'Tidal Basin'. This is just some distilled water. Now the moment you've all been waiting for, the final glory shots. These were all taken right after I finished, so they may not be as spot on as they could be. There are so many angles I could cover, so many details to pick out, I may well take some more when I've tackled tidying the room. 😬 Until then, enjoy the pics and don't forget to vote for me in the competition! Size Warning - All these pics will be posted in original size without hyperlinks you can enlarge them to your hearts content. :thumb: That's all for now folks. All that's left is for you to go and vote! People in the UK could win the same case and PSU used in the mod too. Thanks to everyone who's helped and supported me throughout the process. Hopefully I'll recover from the emotional trauma soon and be back with a new project. Until then crapfans!

-

On the 15th July, someone on another forum commented "wow great start". I thought that was a bit cheeky given how much work I'd put in so far, little did I know he wasn't wrong and the next 2 weeks would descend into chaotic #### I can only now talk about without being reduced to tears. It's been a difficult couple of years, today (7th Aug at time of writing) should have been my wedding day, but instead I'll make do with cricket commentary and build logs. As a sign of just how right WarBoys was, the following and final log has had to be split into 2 parts! 😲 At this stage I was doing about 5 things at once and I could tell the story in actual chronological order, but it would be like a reverse Tarantino and would just be a bit of a mess. Instead I've tried to pluck out threads of parts from the chaos and form some sort of orderly fashion. There are little things that may be missed, but it will make a heck of a lot more sense and at this stage, such was my urgency that I started to forget to take pictures of entire processes. If you have any questions just ask. Lets start with the cables. I shown you I'd started on them previously, having measured the required lengths, cut then crimped. Next up was to start the process of getting them soldered to the female side of the aviator connectors. This would be done in the comfort of the front room. lol First job was to get a good blob of solder on the terminals of the connectors. All 13 done and I was pretty pleased with the job I'd done seeing as how I was a soldering noob. As usual I had my little mod mate Ralph at my heals supervising. Then I stripped the other end of the wires and tinned them. Once tinned, I could hold the wire to the soldered terminal and heat with the iron to melt the 2 together. Had to be careful to get the natural curvature of the wire in the right direction. There were also 3 different length of wire for the 24pin and EPS lines, so had to be careful to solder the right length to the right terminal too. I labelled them all too to make sure they then went to the right motherboard connector. You may have noticed that there are 2 white wires standing out, being used for one of the longer GPU connectors. This is just one of the 'dramas' that befell me in the wiring saga. My original plan, from the design submitted for the competition, was to have the cables bundled inside steel braiding, the type you often see around hoses in an engine bay. I'd already got a sample of it for a proof of concept, but the pandemic dried up all sources of the braiding by itself without paying astronomical prices, postage and then likely import tax to get it from the states. Next I turned to braided shielding 4 core cable, but the thinnest core cable I could get was too thick for the aviator connectors, as was the 18AWG wire I got from pexon. Luckily I had this orange wire I'd bought ages ago when I had orange coolant in my personal rig that was still "18AWG", but just a smidge thinner than the Pexon and had a silicon sheathing that would give a bit more and just fit. However, in the process of figuring out the correct lengths required for all the connectors, some stripper mishaps and just plain bad measuring on my part, I'd ended up just 2 lengths short so had to use the pexon wire. This also meant changes to how the 6pin PCIE connector would be wired, for 2 sets of 3 to 1 set of 4 and 1 set of 2. This would probably work out for the best as I could pull the 2 slightly thicker wires in between the 8pin and the other 6pin wires. Not that you can even tell in the end result. Next up were the rear cables to connect up the PSU to the male aviator connectors. First job was working out which terminals on the PSU went to which terminal of the 24pin. This was not as straight forward as I was hoping, the layout is nowhere near the same and there were 4 terminals on the motherboard side that had 2 cables from the PSU. After a double check and a reverse check, I attempted to remove the cables from the PSU connectors to reuse them, waste not want recycling and all that. Only they would not budge. I couldn't get them out for love nor money so there was only one thing for it, chop of the 24in and use the existing cables! After labelling each cable for where it went in the 24pin, I bundled then into there aviator connector groups and got to work splicing the doubles together. I managed to not take any pictures of the sleeving and soldering of rear cables and I didn't get any pictures of the GPU or EPS process. This is probably due to the difficulty I had in getting into a reasonably comfortable position. I needed the case next to me as I needed to get the lengths right and the orientation and twist on the wires would play a big part. As the rear section would be a horrid dank and dirty affair, the last thing i wanted was pristine sleeving and cable combs, so the cables would need to be able to hold themselves inside the grey SATA sleeving I'd be using. I went from the desk upstairs, to the dining table to the sofa to upstairs to dining table and finally, made a soldering den on the floor of the lounge. In the end they came out alright, despite the trials and tribulations of their production. The poor old soldering iron had taken a beating too. With the main rear section cables complete, It was time to finished the front section with some nifty sleeving in the 'The Division' colours of Black, White and Orange. Heatshrinked at both ends to keep it from going anywhere as I'd had to keep it short and tight to fit it through the covers on the aviator connectors. Was pretty tricky slipping them on, had to put 2 cables through first, then slip the 3rd in in the tiny space between the other 2. The 4th was an ordeal, having to get the other 3 cables exactly where they should be, pull the 4th into position where you could just get the terminal through, then grab hold of all 4 and pull the cover down. Then there was a tricky twist at the end to lock it in. There was really very little room for manoeuvre once on and if they weren't in the right place once on it'd have to come off for another go. Then I only had the motherboard connectors to fit, just push it in... just push it in... push...... in....... nope. They're not going in. 😢 I'd given the ends a quick blast with the lighter to prevent fraying whilst being pushed on. That slight bump from the melted sleeve plus heatshrink was just too much to push in for most of them. At this point it was 4 in the morning. I was distraught at the thought of having to take all the sleeving off and start again, with no idea for how to avoid fraying the ends. So I took myself off to bed to try again the next morning. At this point (23rd July) my body was already suffering badly from having to step up my work volume. This was how much I could clench my hand in the morning when I first woke up. After a coffee or 2 it was back to the sleeving. I worked out that I could get the tip of a knife of tweezers under the heatshrink to loosen it and allow me to pull it back to insert the terminal into the connector then release it and it would jut up nicely against the connector. I still had quite a difficulty getting a couple in having to try and grab the very end with needle nose pliers to push it in. I eventually worked out the the crimping wasn't quite as tight as it should have been (likely due to my cheap ebay crimper or using slightly the wrong size). A quick squeeze with the pliers and they were slimmed up and slid in fine, still catching well inside the connector. Finished! 😄 With the cables pretty much sorted, lets look at some pretty metalwork. I didn't want to leave the rads as great swathes of black, so got some stainless steel louvres to cover them with. The louvres are only 90-100m wide, but a good 10mm deep so will still give plenty of ventilation. As the thin rad would be being placed under the case as exhaust, it would probably improve the performance, directing airflow out to the back of the case instead of straight down into the desk. I couldn't get any the right size, so some chopping would be in order. Such an awkward shape to get a cutting device in there. being stainless steel it would eat Dremel wheels for breakfast, so it would have to be the Jigsaw. After cutting the panel in 2 and trimming some from what was the outer edge, I had to decide how I'd arrange the louvres. For the thick rad that's going in the vertical slot, I didn't want a louvre right at the bottom edge as it might interfere with the fans for the bottom rad and other things going on in the bottom of the case. This would then be attached by 1" aluminium angle (in the background) As if it was meant to be, the aluminium angle sat perfectly against the louvres, keeping them nice and central. The thinner rad is also not as wide, so used half inch angle instead. You might see the holes for the screws are, well, rubbish 😅 Don't ask me what was going on, just went a bit measurement blind. With the protective plastic off, the alu angle cleaned up and some chrome screws with brass washers, you can't even tell and it looks so good. The motherboard tray and rad surround got brushed up and a rub down with WD40 to both protect and bring out the shine. Not that you can tell from the terrible picture. (light, dam it man! 🙄 ) Thermaltake make a massive variety of fittings and adapters in all sorts of colours. I had wanted some that were a straight 90 and combined fitting for the front, rather than the slightly bulkier adapter plus a fitting. Unfortunately with supplies cut off from COVID, I could only get them in black. But where there's a will (and a Dremel) there's a way. With the black paint removed by way of an abrasive wheel, it revealed the beautiful solid brass body beneath. With a very warn wheel, where there was a solid core, I was able to remove the indented lines to make it a bit more solid looking. The line didn't look right with the brass and really improved the 'OEM' feel to the final result. Just beautiful 😍 With a lot of ancillaries done lets turn our intention back to the case. First up was the front IO panel and the corresponding strip across the top of the case. These received a strip of the mild steel used for the internal panels, but with the crap beaten out of it, plus I'd removed most of the plastic ventilation holes in preperation for it's replacement mesh. I also put in a couple of holes for the obligatory anti-vandal switches. But not without drilling them too high and running into clearance issues internally 😖 A bit of dremel action solved that. As for the main case, it had had some damage beat into it in brutal fashion, but it still needed a fair bit of work to achieve the look I wanted. The first stage happened entirely by accident. I'd moved the case with some JB Weld on my hands from the parts I'd just glued and it had rubbed off onto the case. At first I was annoyed but after a bit more rubbing, it actually looked pretty good, an added dirt effect. So I went over the case with the leftover glue, just to give it a light smudge of dirt. Next up was some proper paints: AK's rust streaks and dark yellow enamel wash. Their application was far from 'proper' though, using a combination of old paper towels and scotch pads to apply and remove paint till there was a uneven base coat inside. You can see some new holes that have been drilled in the top right, more on those later 😉 Externally was more about highlighting the damaged metal with rust spots, as well as general grubbiness. It was tricky to get them on and looking "right" having to apply and remove quite a few times till it looked good. I also attached some aluminium extruded mesh to the vents and aged that up with paint too. After that first pass had dried properly I went back to further accentuate with more rust and some run-off streaks. Internally I layered it up in the corners and creases where dust and debris would collect. Next up for the "dirtification" was the internal components. First the PSU which I also removed some of the paint from the corners and edges using a needle file, followed closely by the vaccum. lol Labels and panel covering would also get roughed up before getting some paint on using a sponge, as well as the pump/res. I still needed to do a bit of cable work in the back. Firstly the SATA power, which was trimmed down and a connector removed in between the 2 I needed. I pulled the cable apart and applied some electrical tape where that connector had been. With those and the pump cables all sleeved they looked far to clean to be living back there. Much better 😃 The power and reset switches would also need similar treatment. Seeing as though they would pop out in the front sectionm to connect to the motherboard, I sleeved the end section like the power cables and swapped the 2 seperate 4pin connectors into 1 8pin for neatness and simplicity. The CPU and GPU block RGB cables got re-sleeved to. I may be making them look a mess on purpose, but they'll be a purposeful custom mess! 😂 Next on the agenda we have the case feet, and I figured plastic case feet wouldn't have made it, so would be replaced with 1"x!!x1/8" thicccccc aluminium U channel and attached and supported by some heavy M16 threaded action This meant some big holes in the bottom of the case, a couple of which needed some additional "amendments" to allow the bolts to sit on the bottom properly. Finished off with some dome nuts for extra lift and to provide breathing room for the bottom rad. I also stripped the paint from the bottom and rear panels inside the front chamber with an abrasive wheel and wire wheel. This was much more difficult than anticipated. I had wanted to dismantle the case to allow decent access for painting and paint removal, but with a month getting knocked off the build time and not wanting to weaken the case too much. It was so awkward getting into the corners and other nooks and crannies. Next up a nifty little piece I knocked up that's purely for aesthetics and for the theme of the build, but also happens to feature some nice chunks of metal. A test tube holder! The longer piece of angle sits on the bottom preventing the test tubes falling out and also has holes drilled into it so it can be attached to a fan to keep it secure and upright. This is the kind of thing that happens when you're tired, rushing and not paying attention. Dropped my drill on a can of cutting lube, narrowly avoiding taking the resulting explosion to the face and reacted quickly enough to chuck it out of the shed to stop it spraying over everything. 😳 It also broke my only 3.3mm bit used for M3 bolt holes. 🤬 Now while there will be 9 LED fans in the case, their LEDs will be more used for a decorative theming purpose, rather than illumination. There's going to be a lot of features and highlights, so I'll be using 6 high SMD LED strips in the case. 4 bright white in the fron, 2 warm white in the back. They'll be mounted in aluminium LED housing, these 2 for the top of the case have been drilled and bolted in. The ones for the front panel would need to be re-sleeved. The first one I did had got some glue in the sleeving and I ended up pulling out one of the wires 🙄 Time to put my new found soldering skills to the test. It was attached, but would it work? Like Lazarus! 😄 The LED strips to be put in the bottom were sleeved in grey to fit the metallic scheme Bit of heavy duty double sided tape and they were stuck fast to the newly manicured interior. You can also see the brass G1/8 fittings I'd be using as pass-through ports for the cables. The top LEDs I sleeved in white to match the fan mount, which had been left intact to help with the illumination. But what's that PCB at the back of the case? If you remember the new holes in the back, they're for a PCI bracket fan controller which I'll use to adjust the brightness of the LEDs In amongst the chaos and calamity, there were of course moments where things just came together and worked, like the LED control which at one point I had a dreaded feeling was genuine 4pin pwm control, but thankfully cheap chinesium rules applied and it was in fact voltage controlled. Another was the VERY close proximity of motherboard tray to upper fan bracket and the LED strip to the EPS cables. so many measurements coming together to fit perfectly. 😁 Something I'd had on the to do list for quite some time but for one reason or another had put off, was getting the custom graphics etched into the glass panels. The guys at 4D Model Shop had done a fantastic job with the vinyls and I was so glad I paid the extra to have them do the weeding. I'd marked 3 lines on the masking tape alignment marker and the back of the vinyl to make sure I got it in the right place, which was off-centered thanks to the asymmetrical frame. I gave it a good squeegeeing to remove any bubbles from the edges, there were a few in the middle but nothing damaging. The etching process was fairly straight forward. I started the timer from when I'd finished applying, giving it a bit of a dab about with the brush at 1.5 min and 3.5 min mark and then began to remove it after 5 mins. When removing it, it seemed to have taken quite well then i wiped with a wet cloth and seemingly just wiped it completely off 😕 It turned out it was fine, they is a layer that gets a little attached, but once wiped and rinsed you're left with the etched surface of the glass, which needs to dry a minute to see the full effect. Came out perfect! 😄 As did the others 😃 They were then glued back into their prospective frames. Please forgive the local and backdrop, it was the only place left large enough to house them all. lol You may also notice a small strip of alu angle on the bottom edge of the front window. The foot section housed the bottom lip for the glass and this was a quick fix to prevent any slippage, not that there probably would have been given all the glue I'd used. lol

-

Project ISAC is finished! It has been a hectic last couple of weeks to say the least, I've barely had time to eat or sleep, so for now you'll have to make do with the final competition video, but I'll be back with the final update log and plenty of pics in the next few days. I'd really appreciate it if you'd vote for me in the competition, the link to which is below. Thank you to everyone who's stopped by, commented and offered support and guidance of the last few months. I'm off to raid the liquor cabinet 😅🥃 🍻🍾 VOTE HERE (note that once on the scan website competition page, you'll have to hit the 'vote now' button to take you to a gleam page that's rather large. you'll need to scroll down a fair bit to log in and then the actual voting bit is the 10th gleam entry down)

-

Ahoy hoy Mod fans! A working week since the last update, quite a lot of that time has been spent on a rather large piece of work that I can't show just yet. 32 pieces measured and cut, 102 holes drilled, come to construct it and one of the 2 types of bolt I'm using was too short 😖 Just 2mm longer and would have been fine. 🙄 But new bolts should be arriving in the next day or 2. That's what I've been working on in the shed during the day, but in the evening I've been working on case internals, especially the wiring. Seems even my tools are Division themed 😂 First off are the 36 motherboard cables for the front section, which are all going to be pretty darn short. Then the GPU cables, which have a path even Lewis Hamilton would struggle with. You can also see the loop starting to take shape and 2 nifty little brass ball valves that will be being used. I was very lucky as the 18AWG wire I got from Pexon is too thick to fit into the GX16 connectors, but luckily I had that orange wire got just before the comp when I was planning something with my own rig. Had just enough to get all the front section wires, apart from 1 of the GPU wires, came up just 1 inch short. 😟 So the 6 pin connectors will get 2 orange and 1 white and will hopefully be able to hide the thicker wire in between all the others. There's also been lots of other little fabrication and case work been done. Knocked out these brackets, which you may tell from the treacherous proximity of the countersunk holes to the edge and hastily shortened bolts wasn't quite fully thought through. 🤔 But they work 😄 And now you can see the reason for the deep scoring on that 2nd PSU mount cover. There will eventually be something a little more secure than just a thumbscrew to hold the cover in place 😜 The pump/res is going to be mounted on top of a shoggy sandwich to kill vibrations and noise, but I can't just plank a fat wedge of foam under it and call it a day, so I made a housing for it and got it glued and clamped, but it's still in the shed curing. I might put some holes in the side as the orange and black of the foam fit the colour scheme and a few round holes will make the alu angle look a bit more structural. As the THICC 360 rad will be going in the front chamber and fan in the rear, I needed to make a 30mm hole for it's drain-port and Thermaltake's brilliant rotating drain valve. As well as that there have been a few minor modifications made to the case here and there. I cut out the last rung of the vertical rad support as it wasn't going to be used and was in the way of the pass-through section. A couple of cable tie points needed to be Dremeled off as they got in the way of things, few other holes for cable routing and such and I modded the GPU support bracket to cope with it's decreased living space, but forgot to take any pics. There will be plenty later don't worry 😉 Also needed to put in a few more holes to the new motherboard tray, mostly along the bottom edge. 4 small holes for it to be screwed into the original tray and keep the lower edge steady, 4 larger holes for cable pass-throughs. There's also a couple of holes will sit behind the motherboard itself for a little sneaky sneaky cable management 🤫 That's all for this update folks. A lot of the work being done now with the cables and everything is just very fiddly and awkward and visually very unimpressive. Hopefully have something very soon for you that is. As it's now so far into crunch time that I've no teeth left, I might just pop in with the odd pic here and there. T-minus 7 days 7hours 7 minutes....... Until then Crap fans, stay tuned! Same Crap time, same Crap channel.