-

Posts

50 -

Joined

-

Last visited

-

Days Won

16

Andrew Makin last won the day on November 19 2022

Andrew Makin had the most liked content!

About Andrew Makin

- Birthday October 7

Profile Information

-

Gender

Male

-

Location

Birmingham, UK

-

Interests

I love food, being lazy and copper. ALL THE COPPER!

Recent Profile Visitors

Andrew Makin's Achievements

Experienced Member (3/10)

53

Reputation

-

George Antonopoulos reacted to a post in a topic:

Final Voting Starts Now!

George Antonopoulos reacted to a post in a topic:

Final Voting Starts Now!

-

Sam Ca reacted to a post in a topic:

Final Voting Starts Now!

Sam Ca reacted to a post in a topic:

Final Voting Starts Now!

-

Final Voting Starts Now!

Andrew Makin replied to TT_James's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Amazing work guys. Devastated my poor excuse for a body continues to stop me working at every turn. 😢 My vote is for Sam, just love the concept and the execution is flawless 💜 -

Andrew Makin reacted to a post in a topic:

Final Voting Starts Now!

Andrew Makin reacted to a post in a topic:

Final Voting Starts Now!

-

Inony reacted to a post in a topic:

[Thailand] Krittanon Kidprasert

Inony reacted to a post in a topic:

[Thailand] Krittanon Kidprasert

-

[Philippines] Samuel Callanta

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

So frickin cool man. Love it! -

Andrew Makin reacted to a post in a topic:

[Philippines] Samuel Callanta

Andrew Makin reacted to a post in a topic:

[Philippines] Samuel Callanta

-

Andrew Makin reacted to a post in a topic:

[China] Leo Liao

Andrew Makin reacted to a post in a topic:

[China] Leo Liao

-

Andrew Makin reacted to a post in a topic:

[China] Leo Liao

Andrew Makin reacted to a post in a topic:

[China] Leo Liao

-

Andrew Makin reacted to a post in a topic:

[China] Leo Liao

Andrew Makin reacted to a post in a topic:

[China] Leo Liao

-

Andrew Makin reacted to a post in a topic:

[Philippines] Samuel Callanta

Andrew Makin reacted to a post in a topic:

[Philippines] Samuel Callanta

-

Andrew Makin reacted to a post in a topic:

[Philippines] Samuel Callanta

Andrew Makin reacted to a post in a topic:

[Philippines] Samuel Callanta

-

[Thailand] Krittanon Kidprasert

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Man that's just so good. Superb! -

Andrew Makin reacted to a post in a topic:

[Thailand] Krittanon Kidprasert

Andrew Makin reacted to a post in a topic:

[Thailand] Krittanon Kidprasert

-

Andrew Makin reacted to a post in a topic:

[India] Vinay Agrawal

Andrew Makin reacted to a post in a topic:

[India] Vinay Agrawal

-

Andrew Makin reacted to a post in a topic:

[India] Vinay Agrawal

Andrew Makin reacted to a post in a topic:

[India] Vinay Agrawal

-

Vinay Agrawal reacted to a post in a topic:

[India] Vinay Agrawal

Vinay Agrawal reacted to a post in a topic:

[India] Vinay Agrawal

-

George Antonopoulos reacted to a post in a topic:

[United Kingdom] Andrew Makin

George Antonopoulos reacted to a post in a topic:

[United Kingdom] Andrew Makin

-

[India] Vinay Agrawal

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

That looks fantastic 😃 -

[The USA] Tristin Pivnick

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Turned out great 👍 Can here the 'pling-pling-plinh' of collecting the rings 😅 -

[India] Vinay Agrawal

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

This is looking great 😃 -

Inony reacted to a post in a topic:

[Thailand] Krittanon Kidprasert

Inony reacted to a post in a topic:

[Thailand] Krittanon Kidprasert

-

[Thailand] Krittanon Kidprasert

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Incredible work 💜 -

[United Kingdom] Andrew Makin

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Only the 3 months later than scheduled, but enjoy this intro video for the competition -

Sam Ca reacted to a post in a topic:

[Philippines] Samuel Callanta

Sam Ca reacted to a post in a topic:

[Philippines] Samuel Callanta

-

[Thailand] Krittanon Kidprasert

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Oh wow. That's quite the design concept. Looking forward to seeing this come together. -

[Philippines] Samuel Callanta

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Looks awesome so far 👌 -

Vinay Agrawal reacted to a post in a topic:

[India] Vinay Agrawal

Vinay Agrawal reacted to a post in a topic:

[India] Vinay Agrawal

-

[India] Vinay Agrawal

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Take care man. I've got a horrid cough from all the plaster dust in my house. Not nice. -

Sam Ca reacted to a post in a topic:

[Philippines] Samuel Callanta

Sam Ca reacted to a post in a topic:

[Philippines] Samuel Callanta

-

[Philippines] Samuel Callanta

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Great work 😃 -

52PC reacted to a post in a topic:

[South Korea] Jony Cho

52PC reacted to a post in a topic:

[South Korea] Jony Cho

-

[South Korea] Jony Cho

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Wow, this is looking amazing! -

[United Kingdom] Andrew Makin

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

Ahoy hoy modderinos! Firstly I'd like to apologise to Thermaltake and the other sponsors for the total lack of progress. Life has not been kind to me the last few months; there has been a dislocated shoulder, a broken rib and house renovations that have see long delays leaving very little room in my house for anything. Thank you to Thermaltake for being so understanding and their continued support. Parts have most definitely arrived, even if they're still in the boxes they shipped in, trapped behind half a kitchen. 😅 The Tower 500 looks to be an absolute beast! This is Ralph, my little build buddy. He was especially grateful for the lovely new beds for him to sleep on. Even preferred to his cushioned tent bed 😺 I haven't been completely idle though. While my office was clogged with half a kitchen, I thought I should survey my shed, where the bulk of the modding would be done. It was not good 😬 First job then was to throw out all the rubbish and give it a bit of a clean. A few of the old cabinets from my now destroyed kitchen would make for great storage in here too. The shed was got 2nd hand, and put together by me and a couple of brothers when we were all hungover, so it hadn't exactly been done square and true. The back wall slopes quite a bit and all the rain water caught by the roof runs down it causing a fair bit of damp, so I curred that with a large sheet of tarp that you can see just poking it's head up in the last photo. There were also sizeable panel gaps in some of the corners that would need fixing. It was quite tricky, but using a sturdy screw and a c-clamp i was able to pull them tighter. I then sealed up any remaining gap and holes elsewhere with some silicone sealant. See that fail insulation on the floor? It was attempting to carry 2 of those home that caused the dislocated shoulder. 😂 By the time my shoulder recovered we were well into the heatwave that hit this summer. Good job then that this foil insulation also works to reflect radiant heat back out, keeping the temperature cooler than would otherwise be in a black felt roofed sweat-pit of a shed. With the first strip glued to the ceiling I sat back to admire my work, then went inside for lunch. When I came back and walked under the foil i was hit with a wave of heat. What the ####!? isn't this supposed to reflect it? Lets check fitting instructions..... Oh. You're supposed to fix it an inch or 2 away from the walls and roof. Sticking it with contact adhesive direct to the panels made it into a massive aluminium heatsink. Brilliant 🙄🤦♂️ So off that came and I set about fitting it properly. Getting the foil between tensioned evenly between the beams of the panels was such a pain. It was only right near the end when i found that using a small length of 25x30mm wood to get the gap right made it so much easier. If I did it again I'd do one span between beams per piece, rather than as continuous strip around. Especially when your shed is more crooked than the tower of pisa. I didn't take many pictures of the in-between stage and they're all pants anyway, so here's the finished article Suitable for modding and stopping aliens from ready your mind 😉 I was going to use the tongue and grove pine boards that had been removed from the kitchen ceiling for the ceiling of the shed, but it have a small kitchen and i was about 2/3 through the planks, but only covered 1/3 of the ceiling, so a different approach would be needed, so I ordered a load of sheets of 2.4m x 1.2m OSB Sadly, my trusty tape measure got stood on and broke and no amount of aluminium tape would fix it. It was the first tool i ever bought for myself 😧 RIP I also put some studwork in for where the sheet would end to screw the edges down, while also offering further bracing to the suspect structural integrity. Slowly but surely, the walls and ceiling all got cladded. The roof I was especially pleased with. I had been bit worried about the extra weight, but I got the panels fitting really tightly, requiring some not so gentle persuasion into place, which seems to have reinforced it if anything It was good progress. Just needed to sort some flooring out and get all the tools moved in and we'd be good to go. It had certainly been a tough day finishing off the ceiling, as you might tell from the state of my clothes. After I'd showered and changed, i slipped while wearing my slippers, landing chest first on the arm of my sofa, badly breaking a rib right on the bottom of my rib cage. This has had me out of action for about a month now, but have been feeling much better this last week. Should be getting on it next week when i have some annual leave booked. Goin to be a mad 2 weeks. As a not so subtle hint of what's to come, this mod will be called..... I'm sure you can work out what's it's goin to involve a lot of 🤔🤫 There has been some modding done though, here's a little sneak peak into the next update. So stay tuned Crapfans! Same Crap time, same Crap Channel. -

[United Kingdom] Andrew Makin

Andrew Makin replied to TT Joey's topic in 2022 Thermaltake CaseMOD Invitational Season 1

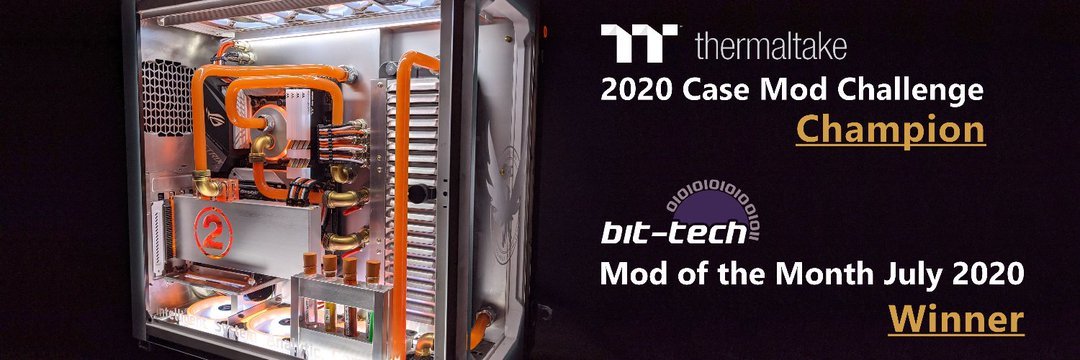

Hi Everyone. I'm Andy Makin, a.k.a The_Crapman/Crappy. It's an old university nickname, don't ask 😅 I won the Thermaltake UK 2020 Case Mod Challenge with my Division 2 themed mod Project: I.S.A.C. (Build Log) Project I.S.A.C. by The_Crapman I'm a former hardware reviewer for bit-tech.net and Custom PC, specialising in cooling and cases. I've been building PC's for over 20years and done watercooling and dabbled in minor mods for about 10 or so, but despite following the modding scene for a long time, ISAC was my first proper full on mod. To win the Thermaltake competition, as well as bit-tech mod of the month and get nominated for Mod of the Year was truly a dream come true. I really pushed myself with that first mod, doing things I'd never done before, and I'm going to continue that trend for this one. I'm no 3d modelling expert, nor am I all that good at hand drawn sketches, all my plans are rough sketches with tons of notes so I know what I was thinking later on 😅 Because of this I can't really share with you my plans, or what the mod will eventually look like, but expect metalwork. LOTS of metalwork 👨🏭 😉 Hopefully you'll join me on this chaotic adventure on what is definitely my most ambitious project to date. Even more so than that time I tried to take over the world with nothing but a wheel of brie and a pineapple 🤨 🤣 Good look to all the competitors. 🤝