-

Posts

26 -

Joined

-

Last visited

Contact Methods

-

Website URL

timpelay.se

Profile Information

-

Gender

Male

-

Location

Sweden

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Timpelay's Achievements

Just Getting Started (2/10)

2

Reputation

-

[Sweden] Tim Malmborg

Timpelay replied to TT Amanda's topic in 2023 Thermaltake RAM MOD Invitational Season 1

-

[Sweden] Tim Malmborg

Timpelay replied to TT Amanda's topic in 2023 Thermaltake RAM MOD Invitational Season 1

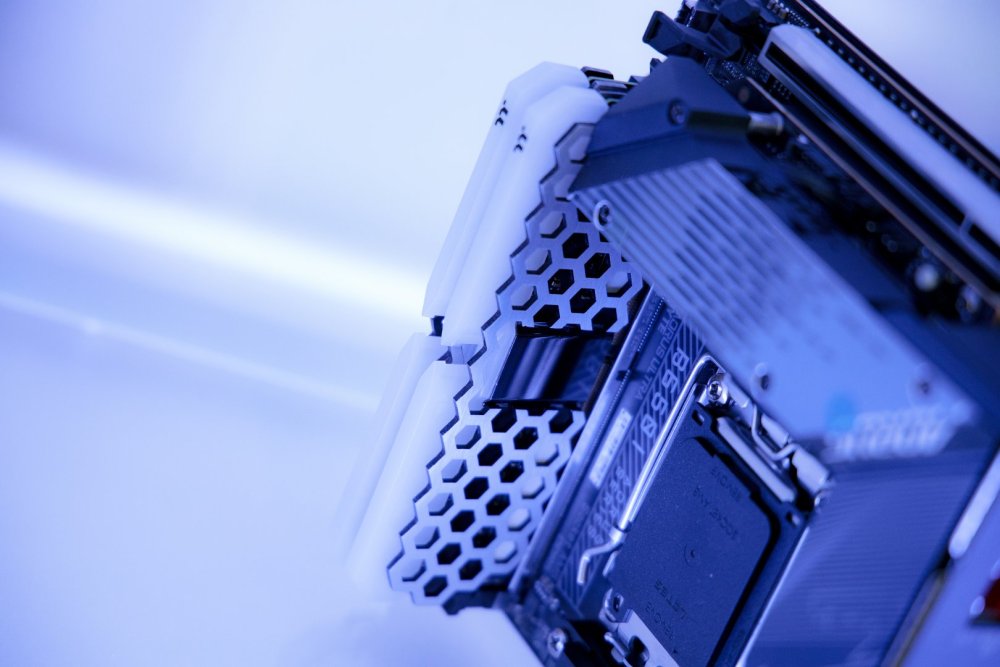

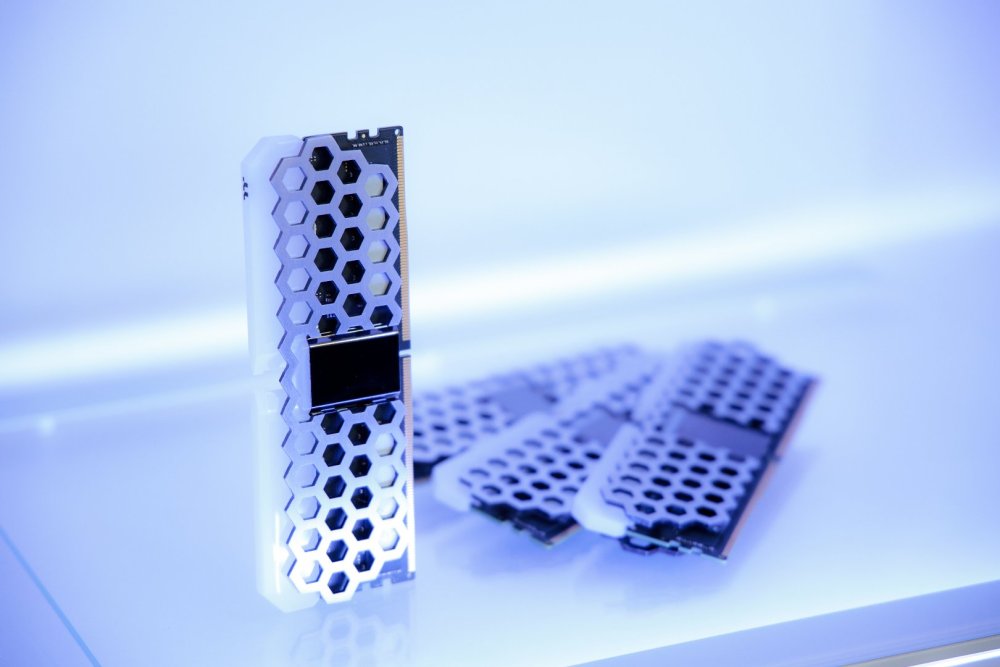

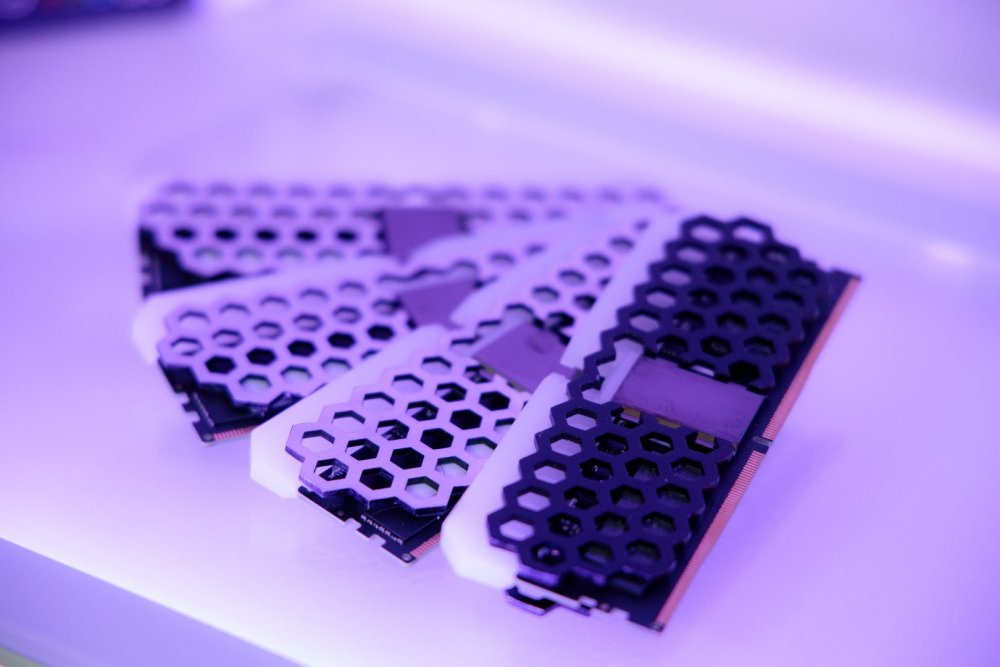

AND they are done! -

[Sweden] Tim Malmborg

Timpelay replied to TT Amanda's topic in 2023 Thermaltake RAM MOD Invitational Season 1

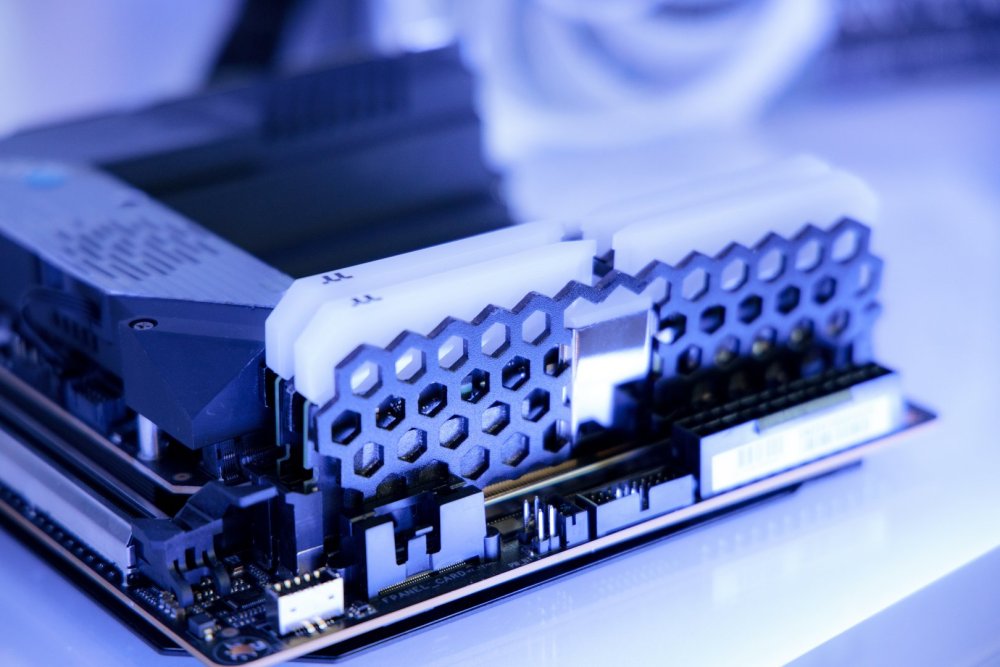

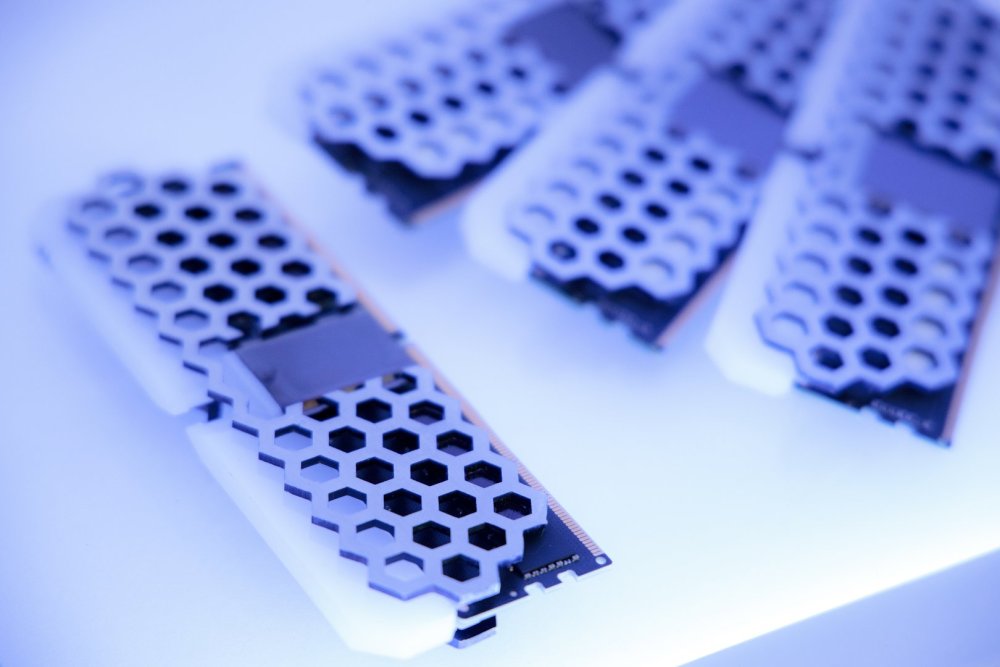

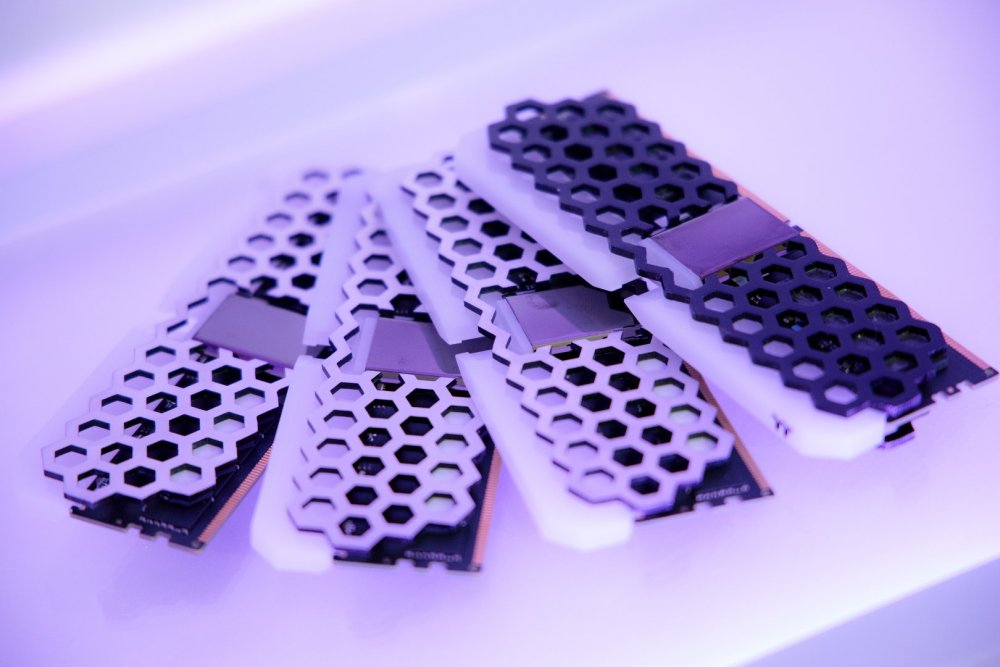

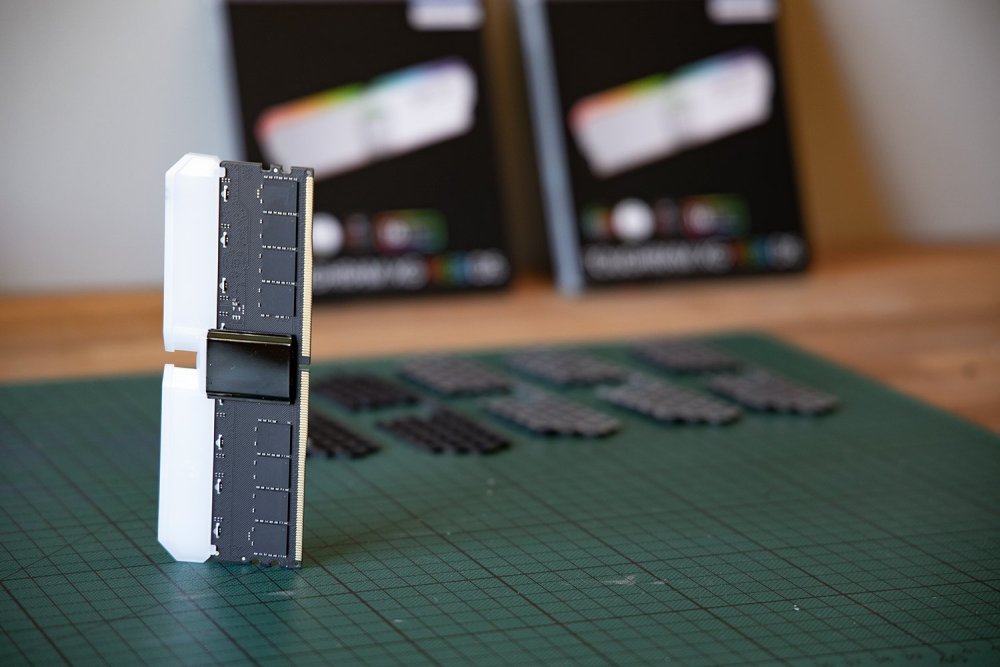

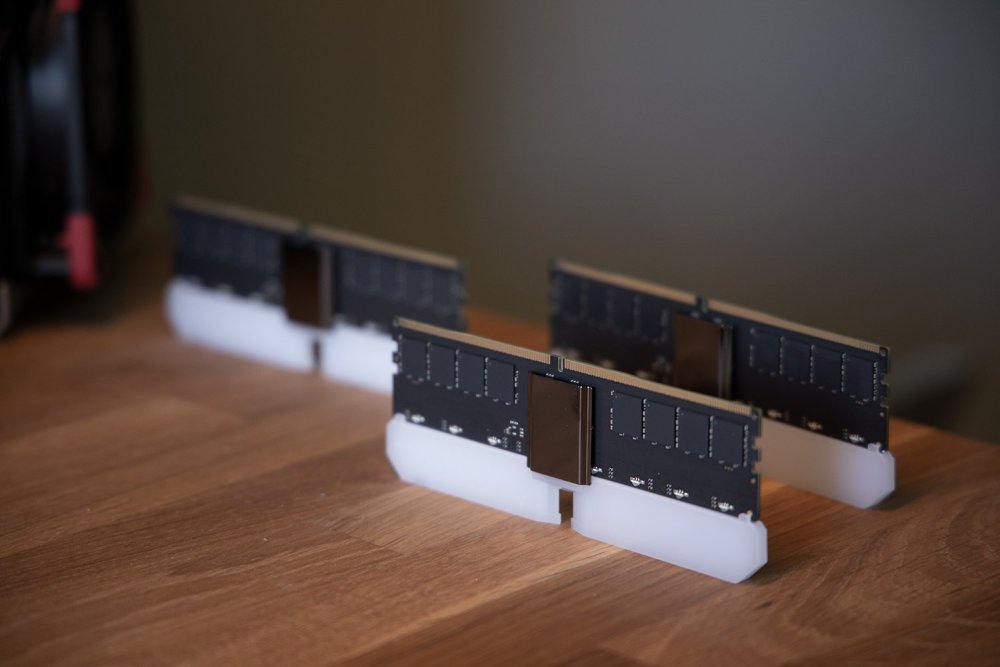

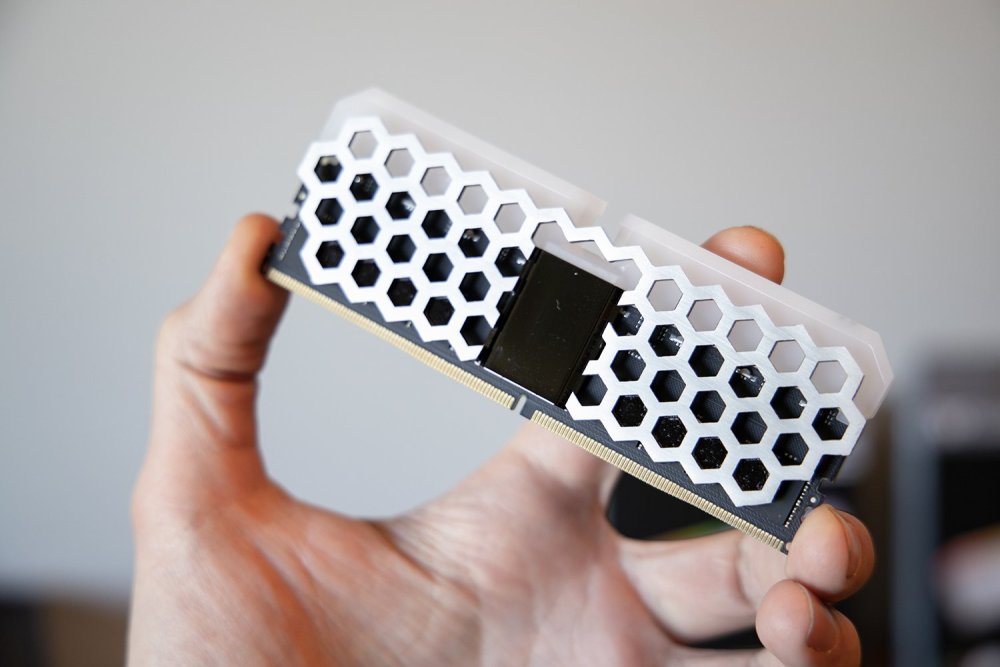

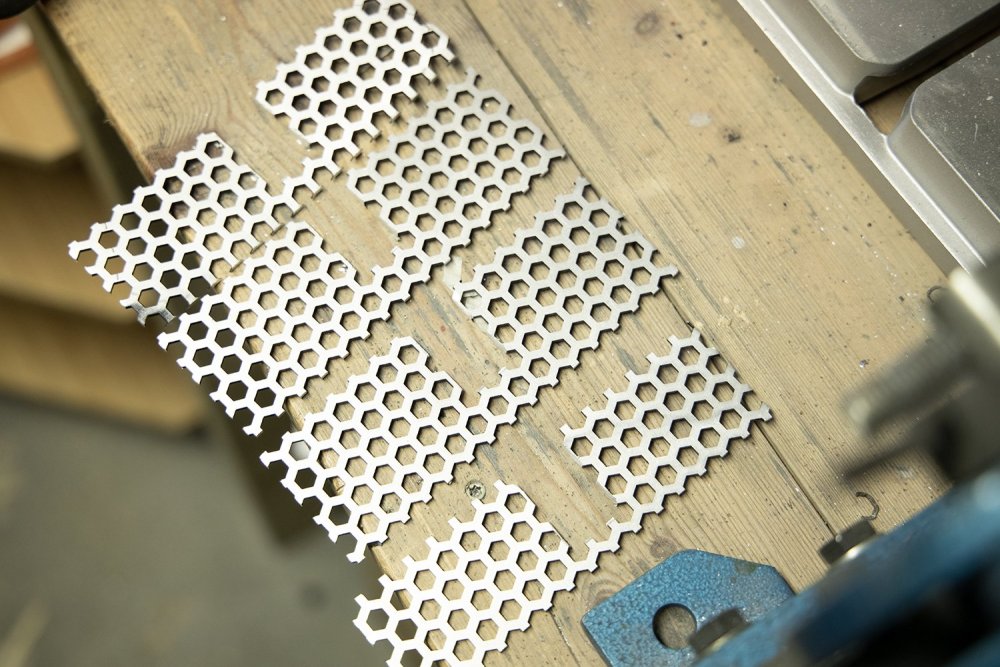

This will be good! Can either use inserts, keep as it is, or paint the pads black inside the combs. Soon finished with all spreaders! Stacking up. Glued the light diffuser to the middle metal plate to keep it tidy in place on the sticks before mounting any spreaders. Assembly time! -

[Sweden] Tim Malmborg

Timpelay replied to TT Amanda's topic in 2023 Thermaltake RAM MOD Invitational Season 1

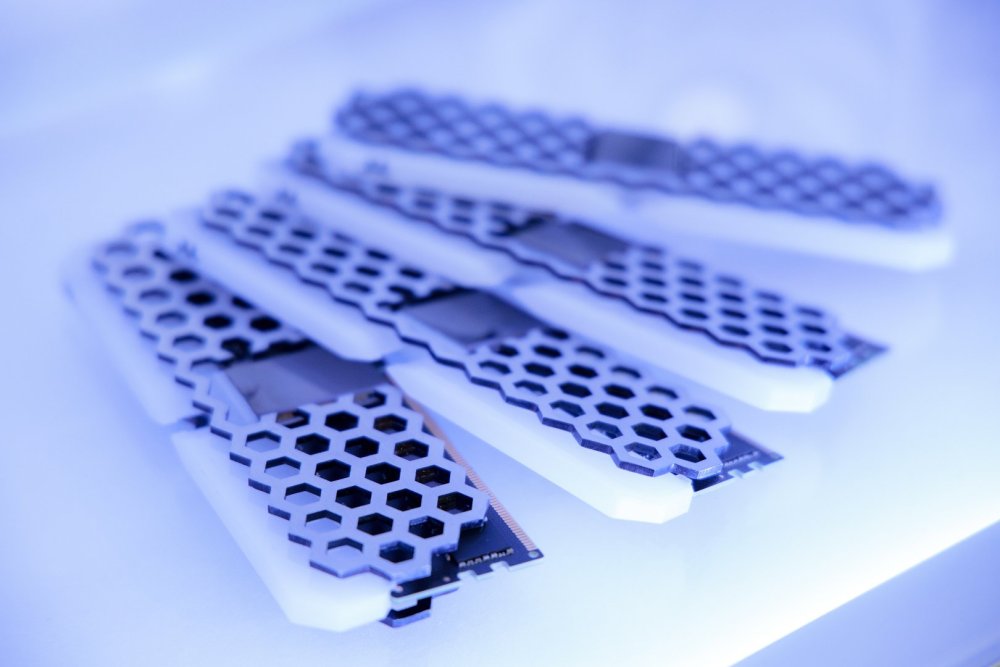

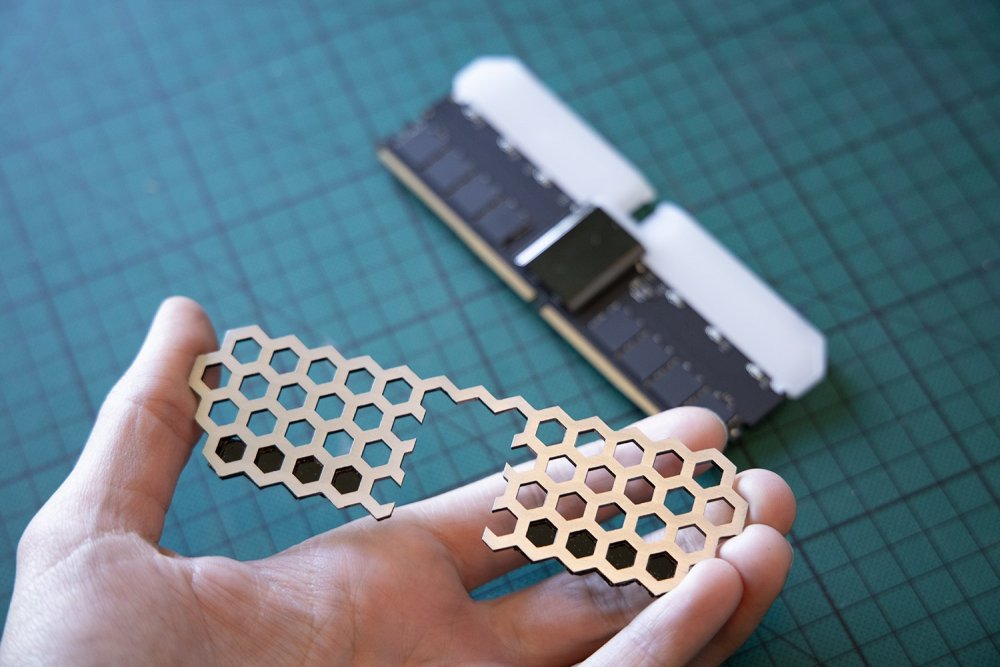

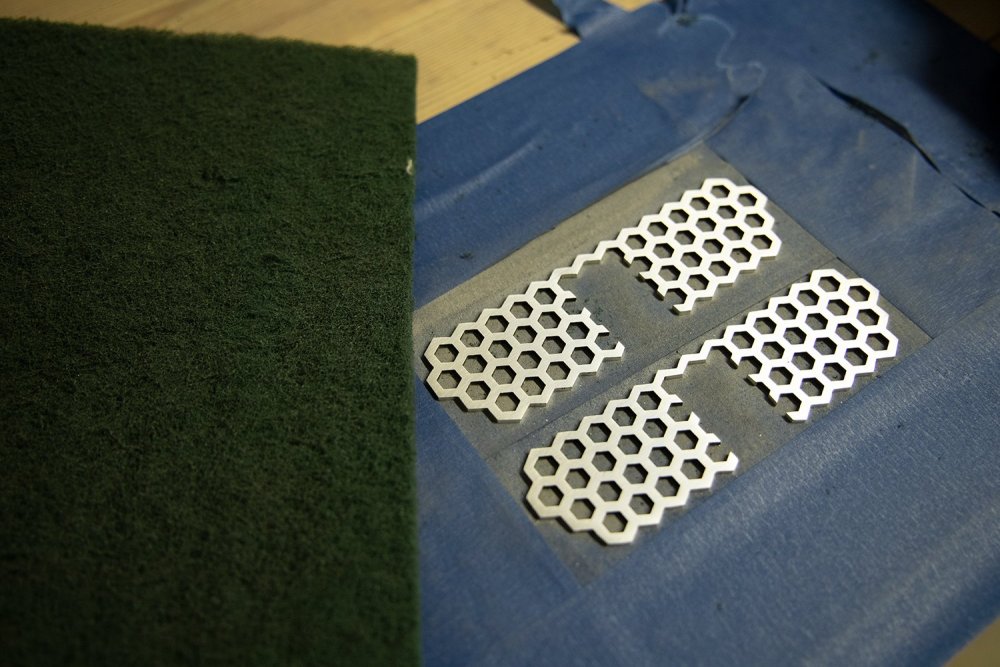

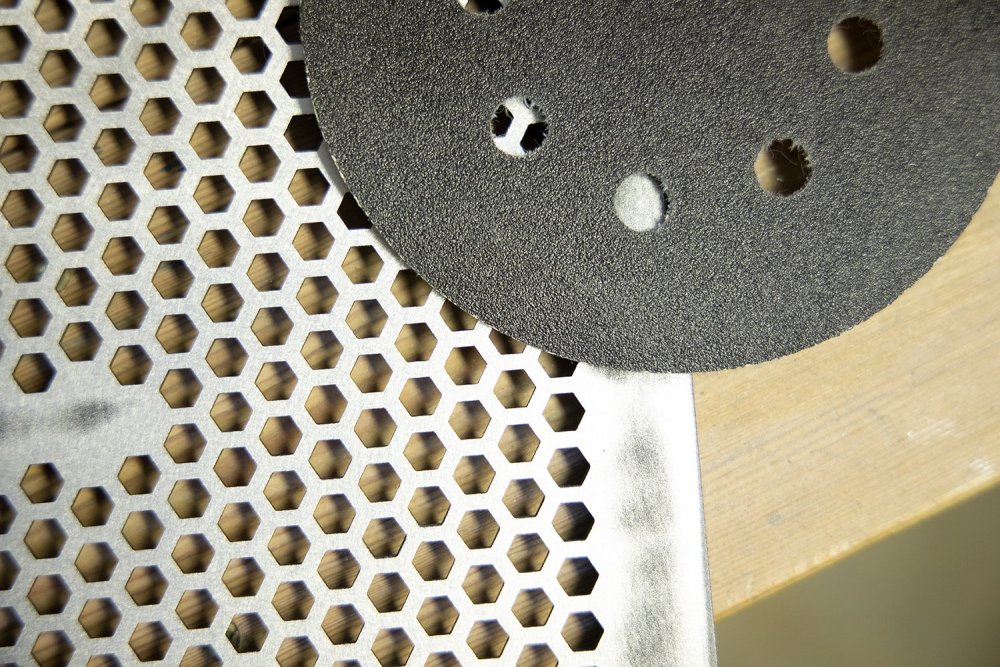

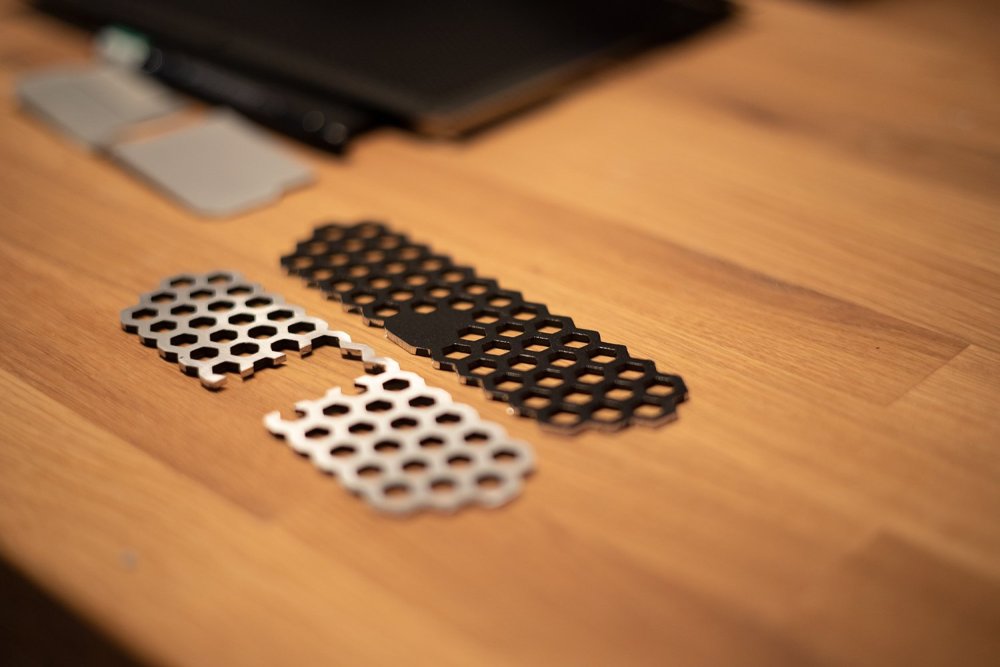

To remove any scrathes and get the final finish I used tape to hold the spreaders flat in pairs when sanding. The 4 bare metal sides are finished and ready for mounting to the actual ram sticks! Worked my way through my stock of thermal pads to find a version that's 1mm thick and really sticky. Lets see if they can hold or I'll order some thermal tape. -

[Sweden] Tim Malmborg

Timpelay replied to TT Amanda's topic in 2023 Thermaltake RAM MOD Invitational Season 1

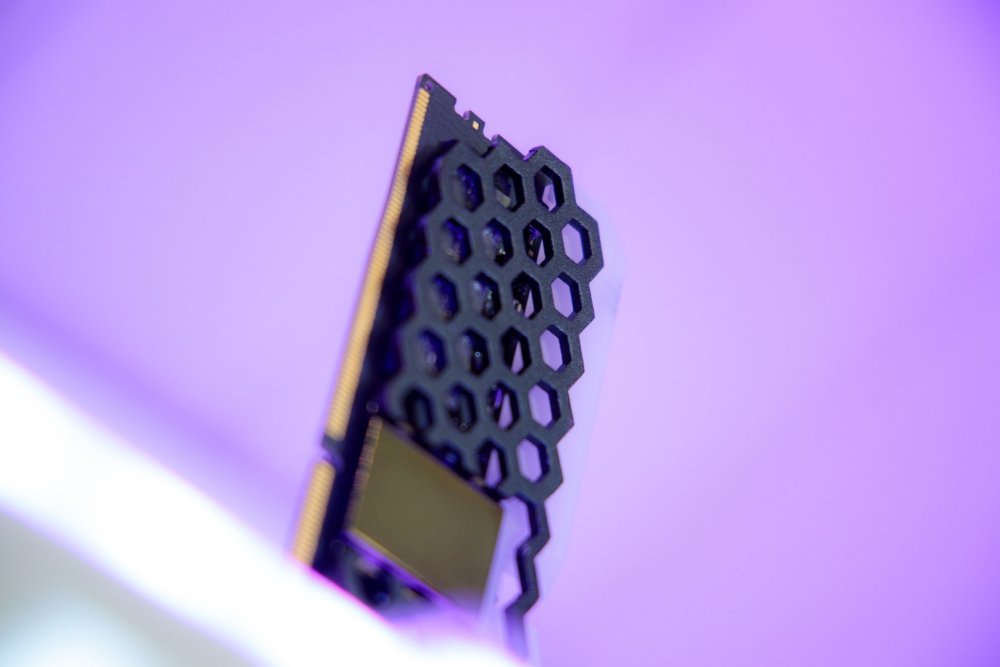

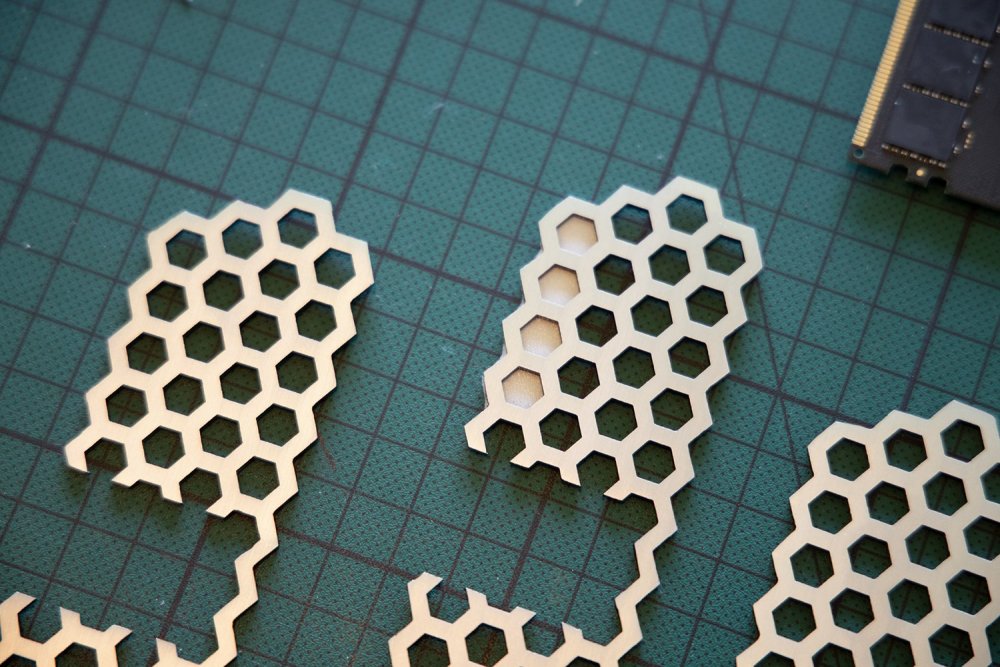

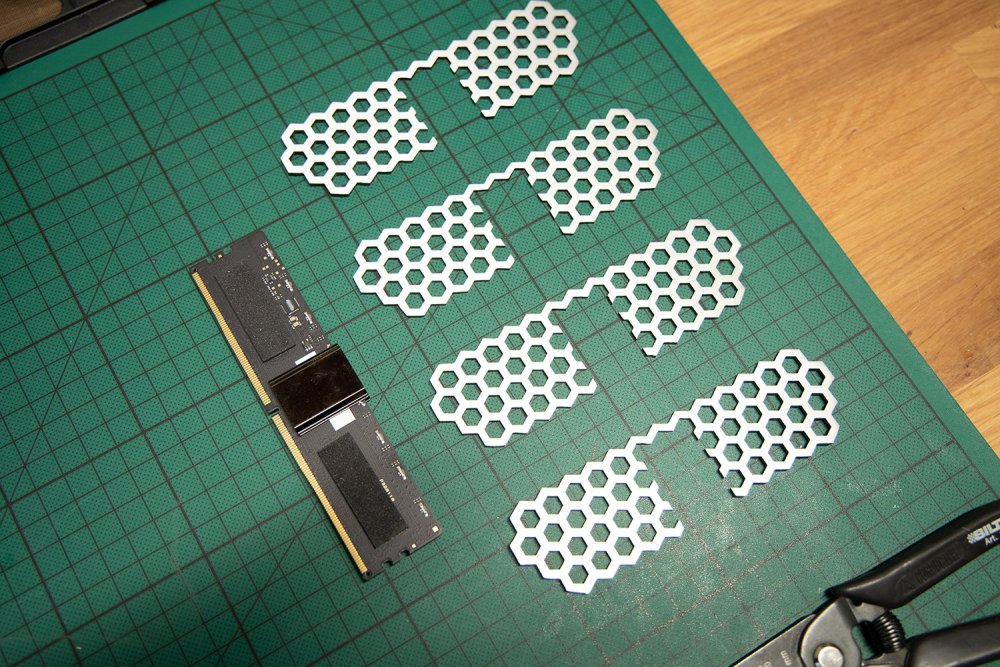

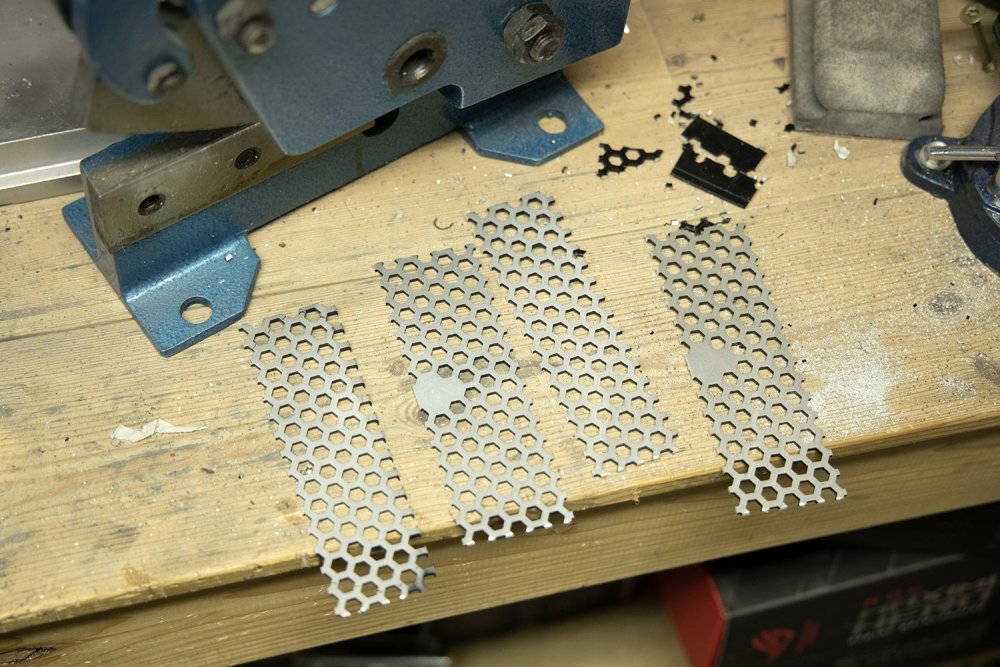

For the second set of 4 heat spreaders I decided to sand and polish the entire sheet before getting into any cutting. I realised that this was much more efficient as I could apply more force with my machine and still get an even surface. After som testing I've desided to go with final grit 600 and hand polish with abrasive cloth instead of mirror polish. This because it will catch the light much better! 80 - 120 - 240 - 400 - 600 grit passes make sure I get what I want With the sheet somewhat in the right finish it's time to start cutting. Did the outlines with my large bench cutter and the middle sections with an angle grinder. Final rough shaping and corner cutting and this is the result: After that I paired them together and use hand files to trim one pair at the time to the right pattern. At last the edges will be sanded and painted. I tried some accent color on some scrab metal I got from cutting and it did not meet my expectation. The black inside and outside edge is much more clean and goes way better with the smooth metal finish. -

[Sweden] Tim Malmborg

Timpelay replied to TT Amanda's topic in 2023 Thermaltake RAM MOD Invitational Season 1

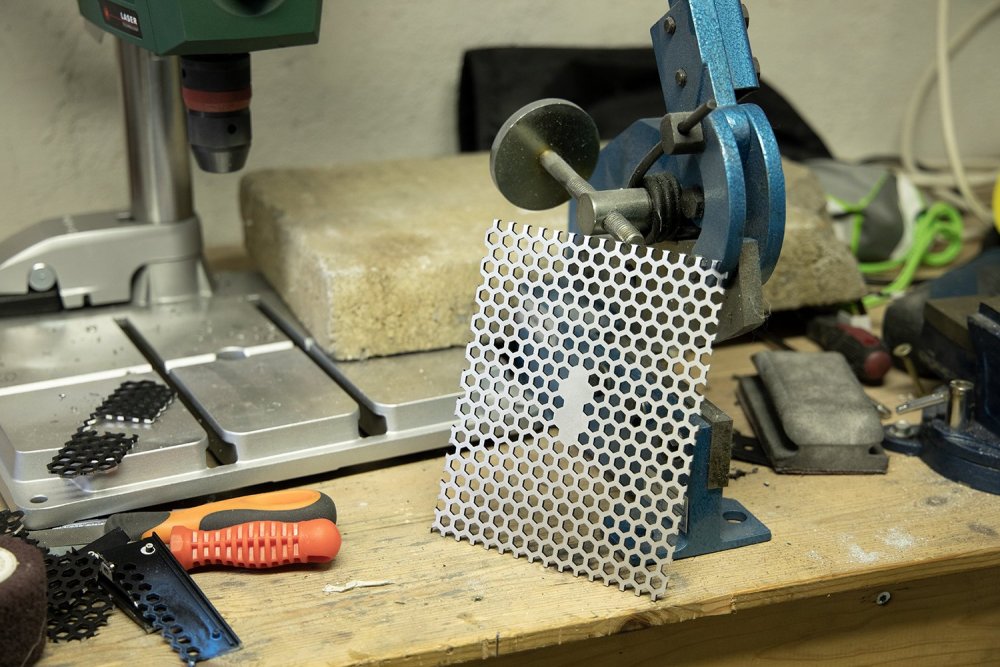

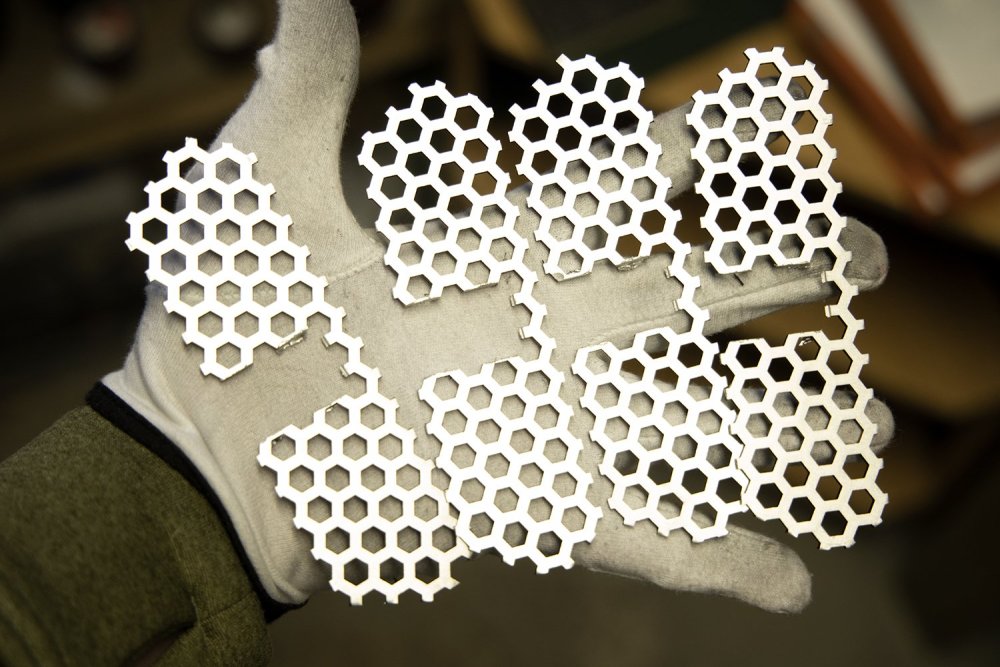

As I want to reuse material I decided to build with these aluminium side panels from another casemod. I tend to save alot of material that could be usefull in the future, and guess what, this is the perfect opportunity. The panels are something like 1,2 mm thick and got this honeycomb pattern that is what I use in many different variations for my brand. I will create new unique see-through heat spreaders for the ram and still be able to keep the center-piece and light diffuser at the top. The competition criteria to stay close to the original design, and yet be unique is important for me. Metal cutter, jiggsaw and files are base tools that I will use to get the heat spreaders into the right shape. The side sanded smooth. There will be a total of 8 heat spreaders when finished. But I'll start with 4 and then try what finish I think is the best. Right now it's tempting to high gloss polish the sides and paint the inside edge of the honeycombs in accent colors. Allthough the combination polished/black is really nice looking. I will probably have to try on some scrap metal to decide. -

[Sweden] Tim Malmborg

Timpelay replied to TT Amanda's topic in 2023 Thermaltake RAM MOD Invitational Season 1

About time to get started! I've been considering a couple of different options for this project before deciding which one to go with. When doing this I came to the conclusion of some things I want to achive: Re-use material or use recycled material. (Reusing aluminium side panels from previous casemods) 2 different surface finishes for the sticks using the same design for all of them. (Smooth bare metal with black edges on one side and blackout on the other) Maintain or improve cooling capacity with the new design. Work with non PC-controlled tools. (Manual metal cutter, jiggsaw, files, sanding/polishing) Focus 100% on the RAM itself Have you ever seen a see-through RAM heat spreader? -

Timpelay reacted to a post in a topic:

[Sweden] Tim Malmborg

Timpelay reacted to a post in a topic:

[Sweden] Tim Malmborg

-

Timpelay reacted to a post in a topic:

[Sweden] Tim Malmborg

Timpelay reacted to a post in a topic:

[Sweden] Tim Malmborg

-

Timpelay reacted to a post in a topic:

[Sweden] Tim Malmborg

Timpelay reacted to a post in a topic:

[Sweden] Tim Malmborg

-

Timpelay reacted to a post in a topic:

[Sweden] Tim Malmborg

Timpelay reacted to a post in a topic:

[Sweden] Tim Malmborg

-

[Sweden] Tim Malmborg

Timpelay replied to Tt Andy's topic in 2019 Thermaltake CaseMOD Invitational Season 2

Thanks! -

Timpelay reacted to a post in a topic:

[Sweden] Tim Malmborg

Timpelay reacted to a post in a topic:

[Sweden] Tim Malmborg

-

ZenModz reacted to a post in a topic:

[Sweden] Tim Malmborg

ZenModz reacted to a post in a topic:

[Sweden] Tim Malmborg

-

[Sweden] Tim Malmborg

Timpelay replied to Tt Andy's topic in 2019 Thermaltake CaseMOD Invitational Season 2

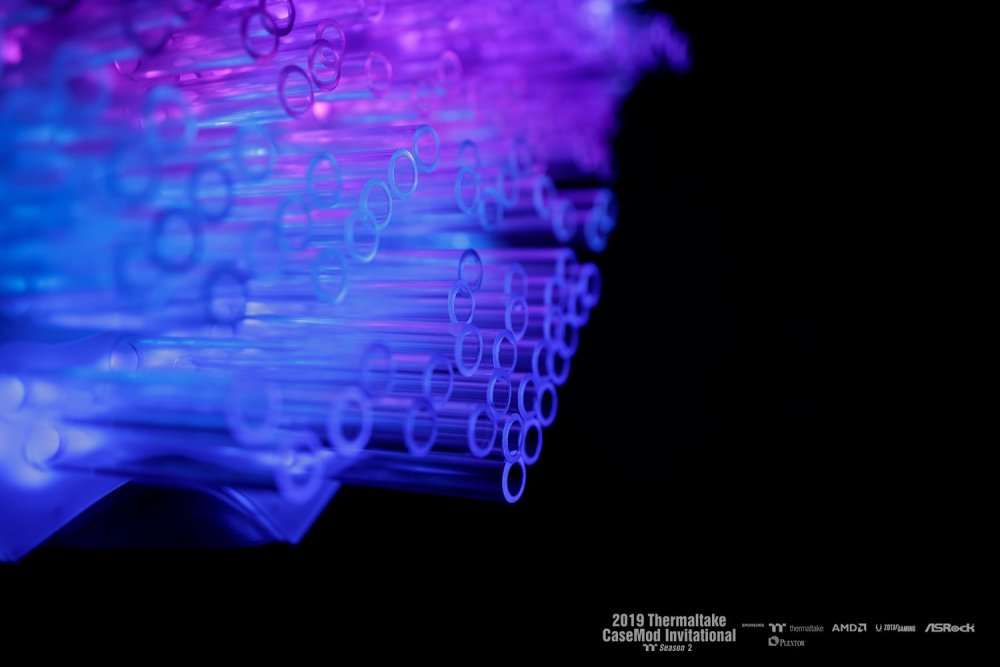

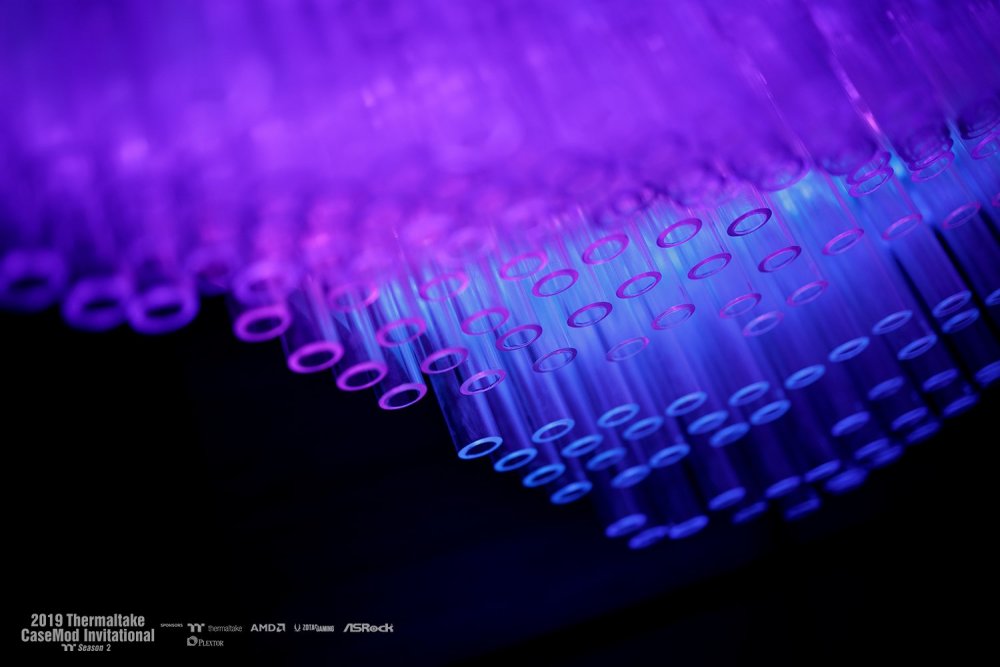

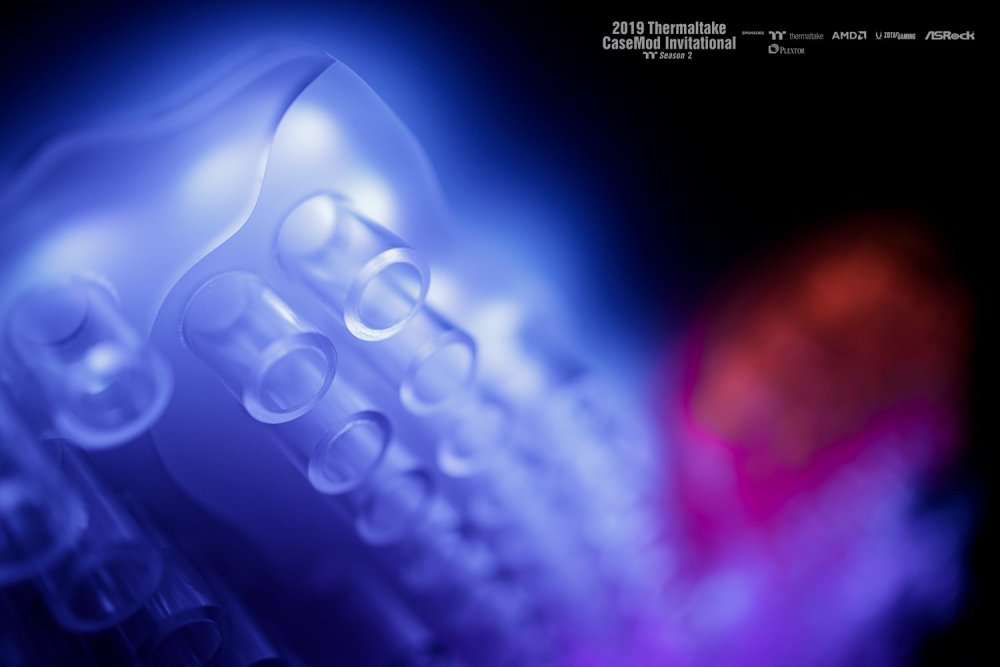

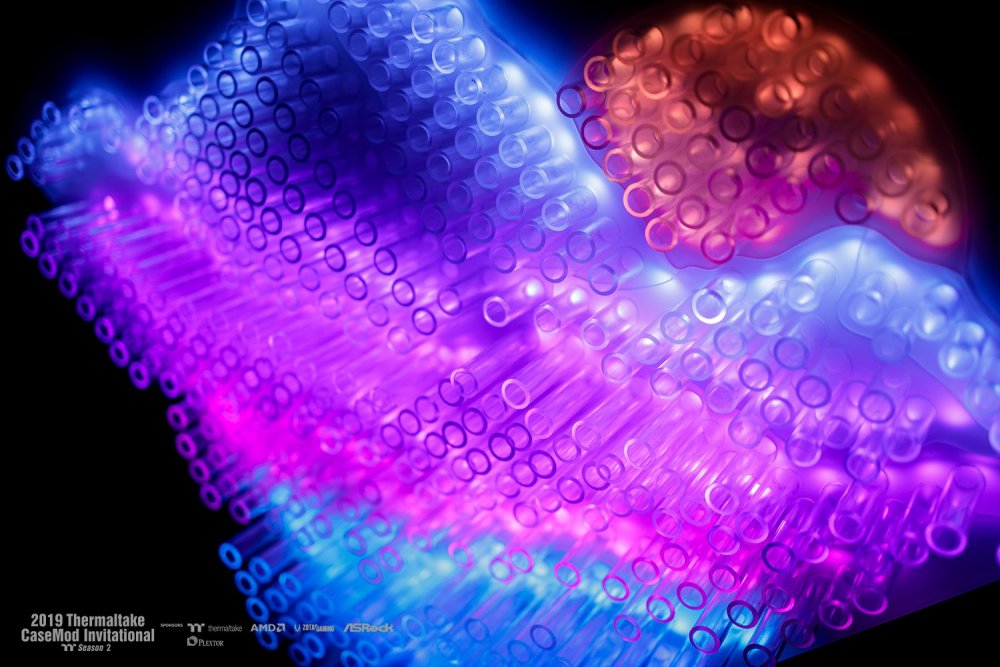

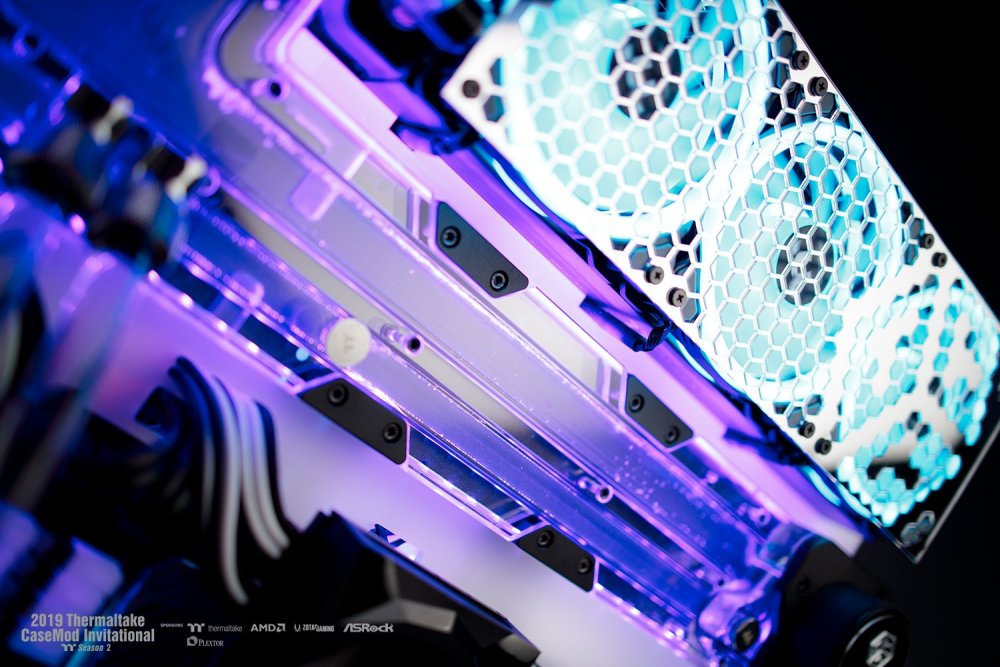

My ambition with this project has been to try somethings that’s not been done before. The Thermaltake P5 is the perfect case for this mission as it’s extremely popular and been previously modded beyond recognition by other modders all over the world. Two key points were set up before the start of this project. • The P5´s original character should be kept. For me, this means doing a casemod were you easily can recognise the original case in the finished mod. • Transforming this case without doing what someone else already have done with it. This meant scanning as many P5 (and similar TT cases) builds as possible before I began my project. The backside straw-art is made from three layers of acrylic. Bottom one acts as separator between light zones and also holds the LED-strips in place for each zone. Middle layer is the diffuse light screen for even light distribution to the pipes. It also acts as the sky with the back painted top section. Top layer holds all ~400 pipes in place creating this magnificent mountain view. As everything is built using TT RGB products ther's possibility to sync and controll by voice through TT RGB Plus - sync all. The front is built to be as slim and clean as possible with laser cut acrylic covers for the entire chassi. Things as CPU-block, pump, fan grille and PSU-shroud are personalized with thin mirror-acrylic. Not that you can't notice, but the entire case is turned to stand on one edge using a 3D-printed stand with a built in turning plate for rotation 360-degrees. Choose side each day! Specification: - TT Core P5 TG V2 - TT Toughpower PF1 ARGB 1200 watt, Platinum - Asrock x570 Steel Legend - AMD Ryzen 5 3400G - Plextor 256gb M9PE NVMe - Zotac RTX 2080 - 32gb TT Toughram RGB -

[Sweden] Tim Malmborg

Timpelay replied to Tt Andy's topic in 2019 Thermaltake CaseMOD Invitational Season 2

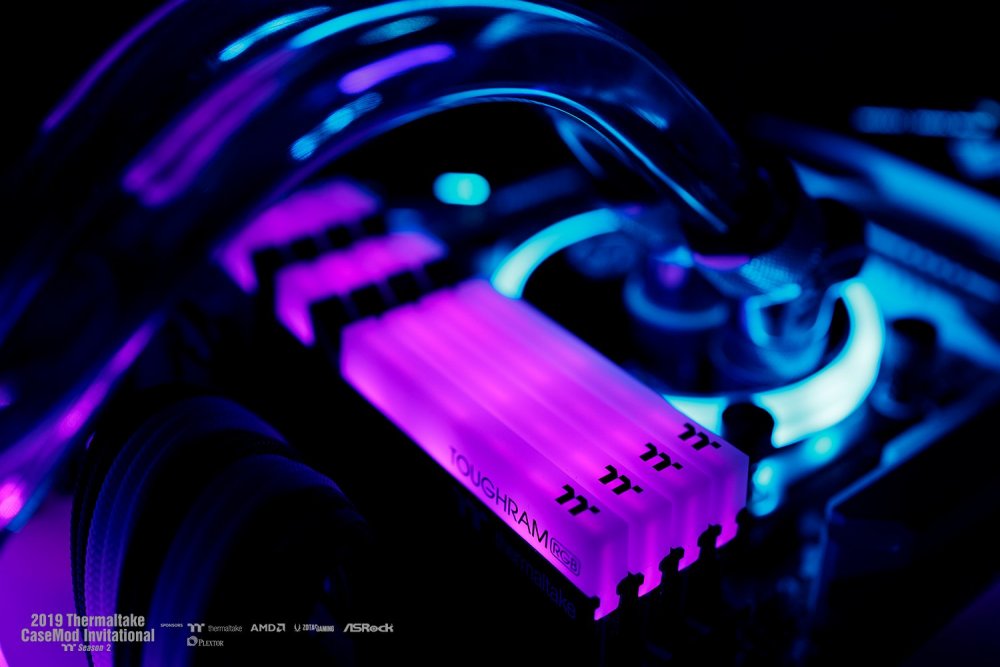

Final assembly! The best part when all parts come together and form what you have been working on for so long! There's much details to show but I will keep that to my final pictures! First start! How about we set som LEDs up See you at the finishline! -

[Sweden] Tim Malmborg

Timpelay replied to Tt Andy's topic in 2019 Thermaltake CaseMOD Invitational Season 2

Thanks! -

[Sweden] Tim Malmborg

Timpelay replied to Tt Andy's topic in 2019 Thermaltake CaseMOD Invitational Season 2

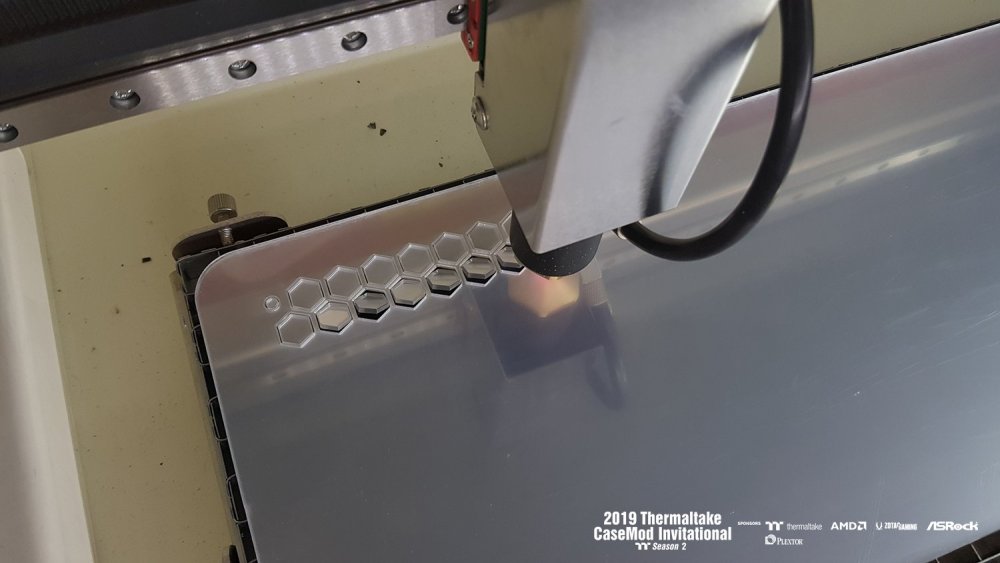

The entire front of the case will be covered with opal - white back painted acrylic. A job that took me alot of time measuring and drawing the case and its components. I then laser cut all pieces after my drawings and had them painted. Here on the picture with the blue protection still on. I also decided to design the covers to be single cable passthroughs for all my sleeved cables. It will look tidy and minimalistic with short cables just entering the acrylic. The sponsored SSD from Plextor is a PCI-E version with integrated M.2 SSD. My layout makes the PCI-E SSD placement tricky and not that clean. So I decided to use the M.2 straight on the motherboard and mod the SSD heatsink instead. I cut it down to a sleek shape and will use it as a cover for the PCI-E riser cable instead. Gonna look pretty #### cool As this mod will be an art piece I will use alot of mirror acrylic to put a new look on things! - Radiator cover - D5 pump back - CPU block - PSU cable shroud Here I'm cutting the radiator cover. I always try to implement my logo and design into every piece of my mods. Will look amazing with the protection removed! -

[Sweden] Tim Malmborg

Timpelay replied to Tt Andy's topic in 2019 Thermaltake CaseMOD Invitational Season 2

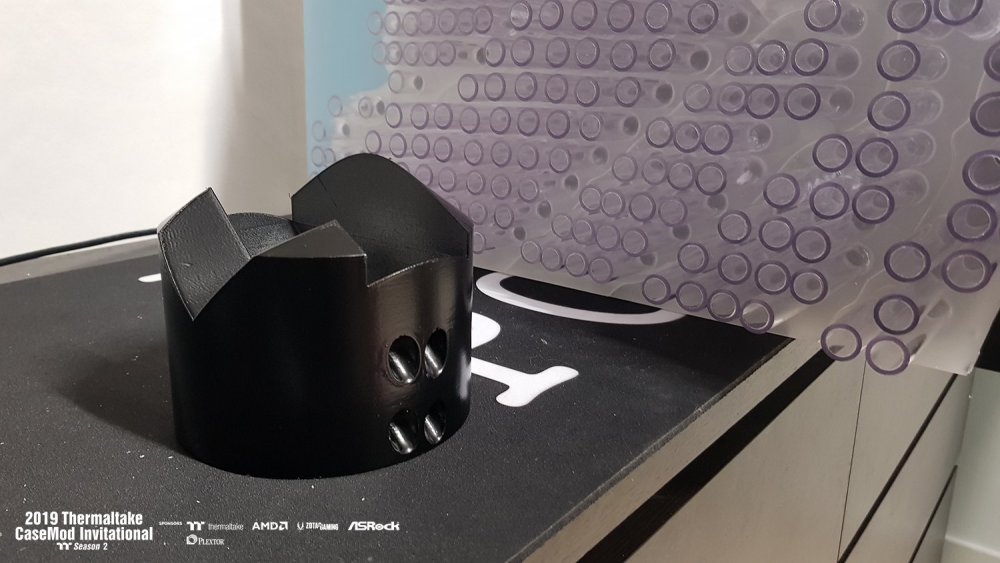

My second revision foot was printed in grey and needed a bit of surface treatment and black paint to keep up to the same level as the other parts. So the mounting procedure is done in a special way to get as stable and possible without any unessesary visual screws. I've attached a laser cut 4 mm thick acrylic ring to the bottom of the foot as the ball bearing turning plate builds approx 10 mm. Then I'll attach a second acrylic to the wooden plate/foot and countersink the turning plate a few mm into it for perfect fit. -

[Sweden] Tim Malmborg

Timpelay replied to Tt Andy's topic in 2019 Thermaltake CaseMOD Invitational Season 2

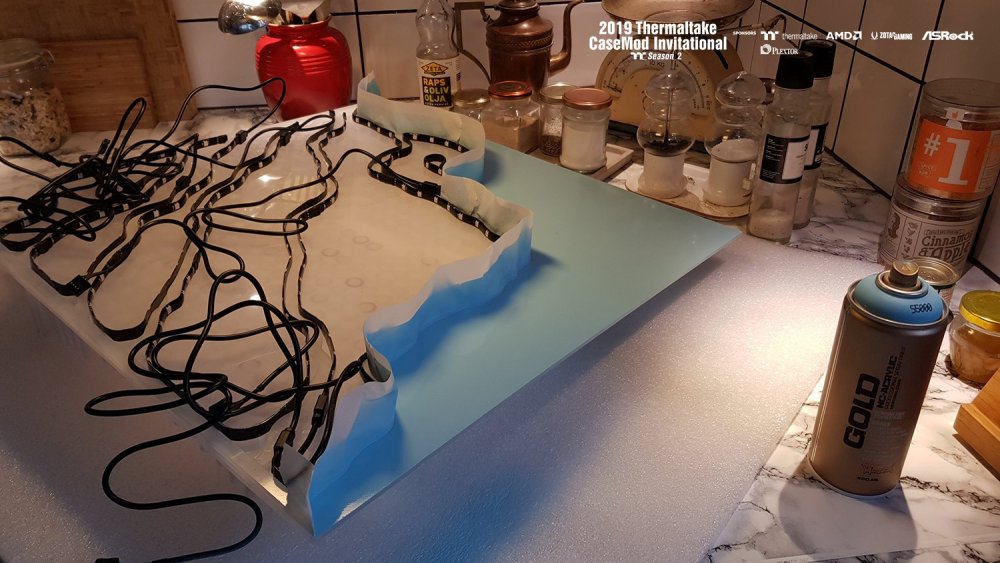

The back panel of the case will need a cut out in the same size as my mountain. This because I want to keep the chassi as slim as possible with the closes acrylic to fit in that space with the led strips. I printed the model on A3 sized paper and taped it together to get the proper outline. I attached it to the backside and used it to jiggsaw the right shape. Here we go! The radiator will still have like 75% direct air flow throughout the perforated section, But as the radiator will be fitted with a 40-50 mm gap all air will easily pass through the vents. The back side acrylic sheet closes to the chassi got the "sky" painted in a light blue color. As the acrylic is diffuse/white this back painted blue will leave a soft color to view at the front. I've decided to not have any lights in this section and also don't want any light to sneak out here. -

[Sweden] Tim Malmborg

Timpelay replied to Tt Andy's topic in 2019 Thermaltake CaseMOD Invitational Season 2

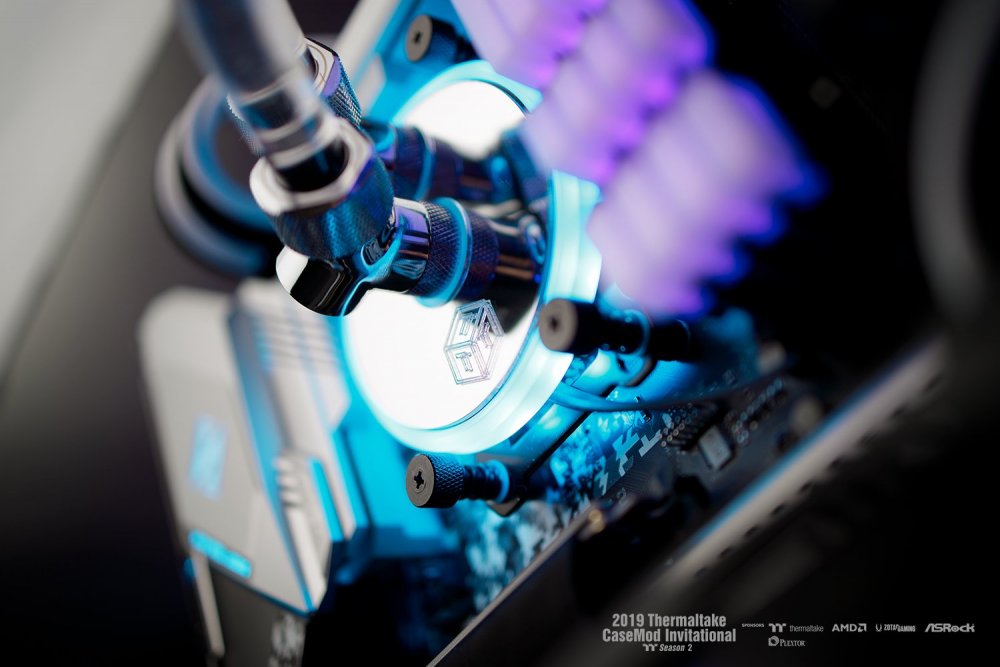

There is often cool to do crazy tube routes with bends, pass-throughs and other stuff. But as this will be an art PC I decided to go for minimalism and actually use just 4 pipes for the entire run. With my modded CPU-block I can use the same parallell bends for the CPU and for the radiator. Full chrome for the CPU and accent black for the radiator. I also choose to use open 45 degrees to the rad which means I can fill at the highest point is nessesary. So satisfied with the good looking bends and the ease of water flow they will provide.