-

Posts

148 -

Joined

-

Last visited

-

Days Won

12

Rob "Deblow" Deluce last won the day on July 17 2023

Rob "Deblow" Deluce had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Rob "Deblow" Deluce's Achievements

Advanced Member (4/10)

54

Reputation

-

aboutsib reacted to a post in a topic:

Project J.A.R.V.I.S

aboutsib reacted to a post in a topic:

Project J.A.R.V.I.S

-

aboutsib reacted to a post in a topic:

Project J.A.R.V.I.S

aboutsib reacted to a post in a topic:

Project J.A.R.V.I.S

-

aboutsib reacted to a post in a topic:

Project J.A.R.V.I.S

aboutsib reacted to a post in a topic:

Project J.A.R.V.I.S

-

RVFER reacted to a post in a topic:

[United Kingdom] Rob De Luce

RVFER reacted to a post in a topic:

[United Kingdom] Rob De Luce

-

RVFER reacted to a post in a topic:

[United Kingdom] Rob De Luce

RVFER reacted to a post in a topic:

[United Kingdom] Rob De Luce

-

TechLinMod reacted to a post in a topic:

[The Philippines] Claricce Lim

TechLinMod reacted to a post in a topic:

[The Philippines] Claricce Lim

-

Juanma García Gálvez reacted to a post in a topic:

[United Kingdom] Rob De Luce

Juanma García Gálvez reacted to a post in a topic:

[United Kingdom] Rob De Luce

-

Juanma García Gálvez reacted to a post in a topic:

[United Kingdom] Rob De Luce

Juanma García Gálvez reacted to a post in a topic:

[United Kingdom] Rob De Luce

-

Rob "Deblow" Deluce reacted to a post in a topic:

[The Philippines] Claricce Lim

Rob "Deblow" Deluce reacted to a post in a topic:

[The Philippines] Claricce Lim

-

Rob "Deblow" Deluce reacted to a post in a topic:

[United Kingdom] Jason Simm

Rob "Deblow" Deluce reacted to a post in a topic:

[United Kingdom] Jason Simm

-

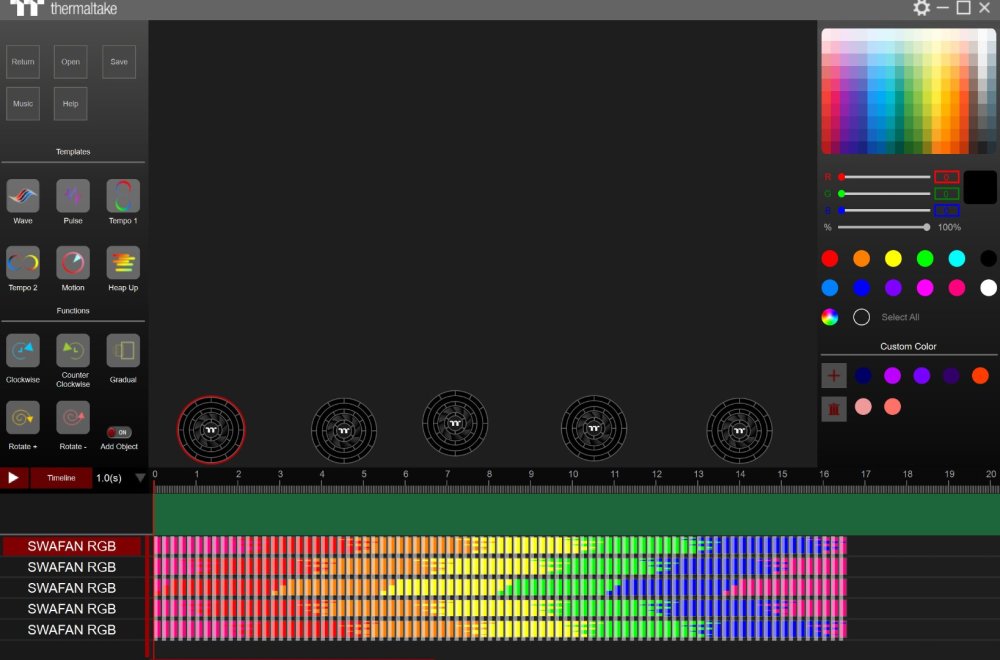

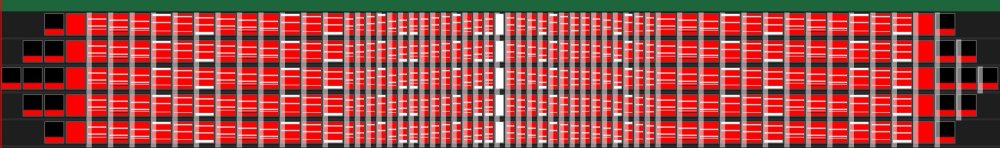

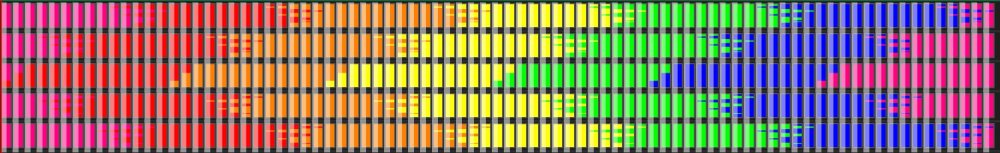

Here's my designs, had fun using the app once I got the hang of it, cant believe ive not used it until now. Most of the designs are ones I would use myself, sorry if the colours don't show well, bit hard for me to film lighting Good luck to fellow modders And heres a little unboxing and rundown on the fans

-

Fantastic! my 14mm Swafans have arrived so I cant start messing with the Neonmaker app, iv'e used the TT RGB app in the past and its done me proud, so hoping the same for this one. Looks a bit more complex, but that just means when mastered you should be able to do just about anything you want with the ARGB fans.....

-

Tefen reacted to a post in a topic:

Event Prediction Voting

Tefen reacted to a post in a topic:

Event Prediction Voting

-

Rob "Deblow" Deluce reacted to a post in a topic:

Event Prediction Voting

Rob "Deblow" Deluce reacted to a post in a topic:

Event Prediction Voting

-

Rob "Deblow" Deluce reacted to a post in a topic:

VOTE NOW

Rob "Deblow" Deluce reacted to a post in a topic:

VOTE NOW

-

Rob "Deblow" Deluce reacted to a post in a topic:

VOTE NOW

Rob "Deblow" Deluce reacted to a post in a topic:

VOTE NOW

-

[UK] Rob De Luce

Rob "Deblow" Deluce replied to TT Lily's topic in 2021 Thermaltake Ultra GIF Design Invitational Season 1

Dropbox link for all GIFs Any issues please let me know. https://www.dropbox.com/sh/53pdsp7dr2zx8ic/AAAnqboWao0ZLeeYfZvbCekha?dl=0 -

mainframe reacted to a post in a topic:

[UK] Rob De Luce

mainframe reacted to a post in a topic:

[UK] Rob De Luce

-

[UK] Rob De Luce

Rob "Deblow" Deluce replied to TT Lily's topic in 2021 Thermaltake Ultra GIF Design Invitational Season 1

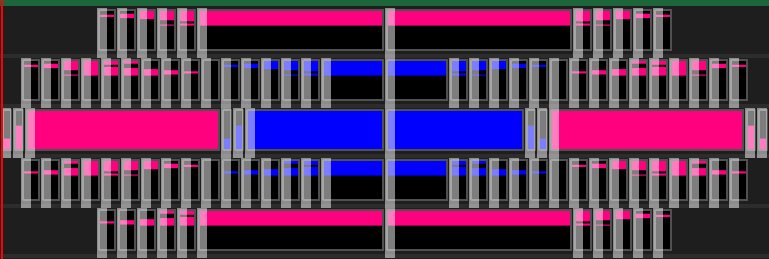

Here is the GIFs in action, forgive the film quality as its hard to show the actual image quality but be assured the screens look cool! -

[UK] Rob De Luce

Rob "Deblow" Deluce replied to TT Lily's topic in 2021 Thermaltake Ultra GIF Design Invitational Season 1

And here are some more extras that didn't make the top 5 for me but still might look good for some setups. GO WITH THE FLOE A phrase many will have heard, so had to be done. FLOE TEXT ver2 Another version of the first floe text using another version of water bubbles as background then added text created in photoshop. TT logo -

[UK] Rob De Luce

Rob "Deblow" Deluce replied to TT Lily's topic in 2021 Thermaltake Ultra GIF Design Invitational Season 1

ICE COLD (5th of main 5) Well as the Floe RC is a cooler it made sense to try something super cool like ice, this set of clips took the longest to do as they failed several times. Filmed on my cooker, floor using LED lighting and a hair dryer, each clip took about 20 minuets to melt the ice, then I added effects and reversed the video to make the text look to be icing up as its soooo super cool! This set can be used on CPU and RAM like most others by rotating them in the app, so I have left some 480x480 so you can decide, black space at the bottom of one so you can clearly see the PC stats also. Main set 5 -

[UK] Rob De Luce

Rob "Deblow" Deluce replied to TT Lily's topic in 2021 Thermaltake Ultra GIF Design Invitational Season 1

LIGHTNING FAST (4th of main 5) Ok so this one is a bit different, this is based on the DDR (ToughRAM RC) most have black backgrounds to help the text pop, but one also has another version of my water flow background. The lightning was the hard part, making it move with the text and flip without looking too fake. Main set 4 EXTRA Versions -

[UK] Rob De Luce

Rob "Deblow" Deluce replied to TT Lily's topic in 2021 Thermaltake Ultra GIF Design Invitational Season 1

FANTASTIC (3rd of main 5) You still need some fans when watercooling, so why not add a couple more fans to your setup. Filmed on my kitchen table with black background then I created the text and effects for the final GIF. Main set 3 -

[UK] Rob De Luce

Rob "Deblow" Deluce replied to TT Lily's topic in 2021 Thermaltake Ultra GIF Design Invitational Season 1

FLOE WATER & FLOE TEXT (2nd of main 5) Filmed using my sister tea jar, strong LED lighting at the bottom, black background and adding water to create the bubble flow effect. The text was done on my phone using a pen to wright the text and add the effect, some are individual letters that's been edited together, removing the black background from the text allowed me to add the water effect to the background for some extra flow. Main set 2 EXTRA Versions -

Rob "Deblow" Deluce reacted to a post in a topic:

REVIEW TO REDEEM!

Rob "Deblow" Deluce reacted to a post in a topic:

REVIEW TO REDEEM!

-

[UK] Rob De Luce

Rob "Deblow" Deluce replied to TT Lily's topic in 2021 Thermaltake Ultra GIF Design Invitational Season 1

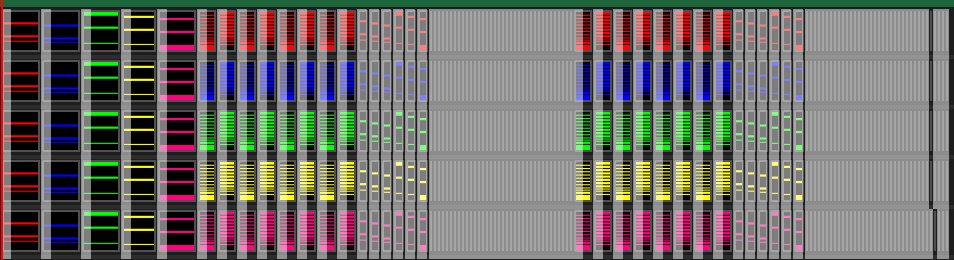

All my themes are mostly based on the product they're intended for and the main purpose of the Floe RC, cooling and waterflow. SANTA SNOW FLOE (1st of main 5) As its close to Christmas and Christmas is normally the coldest part of the year in the UK, I thought I would do a snow and Santa theme. I like to try different things and I'm never 100% happy most the time, so i have a couple of versions of many of the GIFs for people to pick from if they like them, fake snow, real snow, Santa and no Santa versions. Filmed using Tt RGB LED strips, fake snow on the ground, fake falling snow and most have animated snow falling or none. Several speeds and lighting conditions create the different effects. Main set 1 EXTRA versions -

[UK] Rob De Luce

Rob "Deblow" Deluce replied to TT Lily's topic in 2021 Thermaltake Ultra GIF Design Invitational Season 1

Some more progress vids, stage for the snow GIF and letter editing